Cheap Aluminium Coated Pet Mpet Film of Laminating Roll

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

cheap aluminium coated polypropylene pet mpet film of laminating film roll

Quality: 100% virgin pet

HS Code: 777309664

Processing Type: Multiple extrusion

Thinckness: 8mic-12mic

Main size: Width≤2350mm

Length 18000m/9000m/6000m

Usage: 1)PET food grade packing film2)PET printing film, pet release film

3)Metalized pet film,cpp/pet sealing film

4)Pet laminating film

Remark: All the indicators could be customized which includes the thickness, width, length, diameter.

Product Description

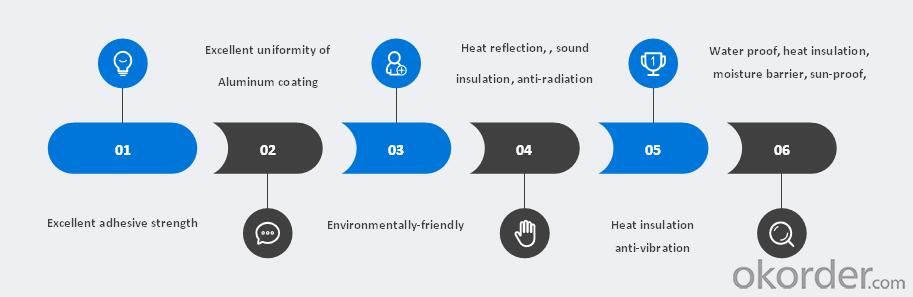

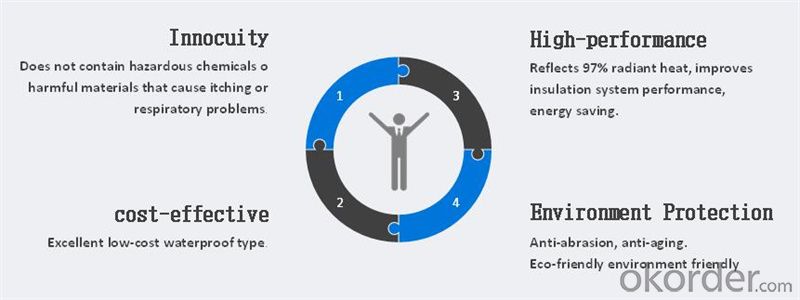

Our Advantage

Superiority of price: we control the whole process from raw materails purchasing to final product manufacturing.

Efficiency advantage: the fastest time of delivery is 7days.

Customization: all indicators could be customized which includes the thickness, width, length, diameter.

Usage

1) 12mic silver metalized PET film coated PE is used to laminated with EPE foam or Bubble as thermal Insulating materials, which could be used as underlay, wrap wall insulation materials,

2) To make sunshade or ice bag;

3) Used as emergency blanket, it can retains 80% percent of your radiant body heat

4) To make static shielding bag for electronic product

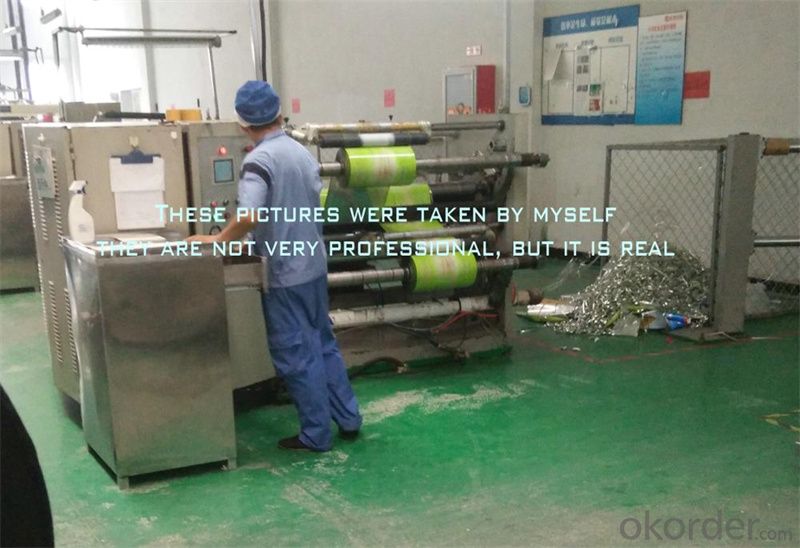

WorkPlace:

This is our metalized polyester pet film produce line,

you can visit our factory at anytime,

we asked workshop clean and tidy to ensure that the product with high quality and error-free.

Device Show

- Q: How to choose the plastic film for the salt packing bag?

- Indeed our common combination of corrugated carton packing bag, composed of inner and outer packing, is a kind of design idea, size material, performance, the design of the packing bag you need, but also need to design the packing box loading specifications, stacking layers, material strength, etc..

- Q: What are the factors affecting the permeability of plastic film?

- Water column height. In the water permeability test, the water quantity in the water cup is changed, indicating that the water column height has no influence on the test result, so the water quantity is not strictly controlled, and the amount of the water can be poured into the water permeable cup with proper amount of water.

- Q: The plastic film on the mattress doesn't tear off. Is it good for the body to sleep?

- The plastic film on the mattress doesn't tear off and the sleeping doesn't affect the body, because it also cushions the bed and makes the bed list.

- Q: In a bowl with the seeds covered with plastic film, you need time off the air

- Plastic film cover in order to keep the soil moisture in the soil, air breathing for seed germination and growth of enough, only to grow seedlings, to remove the cover film, otherwise the film may have a high temperature.

- Q: What is the density of the common PE films?

- PE film, that is polyethylene film. Polyethylene plastics are of high density, medium density and low density. Generally linear low-density polyethylene density: 0.91 - 0.965g/cm3 (g / cm3).

- Q: How can the weathering of the plastic film on the surface of FRP be removed?

- Corona treatment. It is commonly known as electrical discharge treatment, which is the most common treatment for plastic film production, printing and compounding. The process of EDM processing is that processor release high frequency and high power, produce small dense purple spark to the impact surface of plastic film, chemical bond breaking molecules on the surface of plastic film and degradation, increased the surface roughness. In addition, a large amount of ozone is generated at the same time of discharging, and the surface of the film is oxidized to produce a strong polar group, such as carbonyl group and peroxide, so that the surface of the plastic film is roughened, and the surface tension of the film is enhanced.

- Q: When will the plastic film be opened when the vegetables are sprouting?

- Plastic films are made of polyvinyl chloride, polyethylene, polypropylene, polystyrene and other resins. The surface tension of the plastic film depends on the free energy of the surface of the plastic film, and the surface energy of the film depends on the molecular structure of the film itself. Plastic film can be used in food packaging, electrical product packaging, daily necessities packaging, clothing packaging, etc..

- Q: What are the appliances for drawing plastic films?

- The tensile strength is divided into longitudinal and transverse directions. Plastic film material in a certain direction, through the tensile fixture test speed, tensile until fracture, showing the carrying capacity.

- Q: Does the plastic film on the bank card fall off and affect the use?

- No effect, POS bank card consumption is mainly using credit card, magnetic stripe information verification card, the card back card so that film damage does not affect the use.However, note that the convex character is useful, some businesses in the absence of POS, or when the equipment failure, the pressure of card transactions, especially in foreign businesses, so the card face film bad never mind, if if Braille was flattened, suggest you still for a new card.In addition, the film is not good, it is necessary to change the card

- Q: Why should a plastic film be covered after civil construction?What's the point? Do you have any requirements for plastic film?

- The plastic film has no special requirements, as long as the cover to prevent water evaporation. In the cold season construction to cover the mats and other things to keep the temperature.

Send your message to us

Cheap Aluminium Coated Pet Mpet Film of Laminating Roll

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords