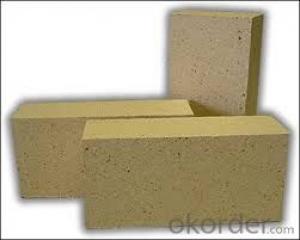

Fireclay Brick Ceramic Fiber Blanket Refractory Blanket 1260C HP

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 225 roll

- Supply Capability:

- 31500 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General information:

Cmax ceramic fiber blanket is made from high quality gao-ling clay, high purity alumina and silica oxides by spun or blown process. It is asbestos free. No chemical binder is added. Double-size needling provides blanket with great tensile or handling strength for easy installation. Blankets are available in various classified temperature from 1260ºC to 1430ºC.

Cmax ceramic fibre blanket is resistant to most chemicals attack except hydrofluoric phosphoric acid and high pH alkali(na2o or k2o). Its thermal and physical properties can not be affected by oil, steam and water, very good thermal insulating materials.

Advantages:

Heat reflectance

Light weight

Low thermal conductivity

Low heat storage

Flexible

Resilient to thermal stock

High tensile strength

Corrosion resistance

Easy to install

Asbestos free

Application:

Petrochemical process heater refractory fiber lining

Heat treating furnace or intermittent (shuttle) kiln hot face lining

General furnace backup insulation

Heat seals for kiln car or furnace door

Electrical insulator

High temperature acoustic

Fire protection

Non-standard sizes are available upon request.

This information, subject to change, is offered solely for your consideration. Users of our products should make their own tests to determine the suitability of each product for their particular purposes.

| TECHNIQUE DATA | |||||||

| STD | HP | HA | HZ | ||||

| CLASSIFICATION TEMPERATURE(C) | 1260 | 1260 | 1350 | 1450 | |||

| WORKING TEMPERATURE(C) | 1000 | 1050 | 1200 | 1350 | |||

| COLOR | WHITE | WHITE | WHITE | WHITE | |||

| BULK DENSITY(kg/m 3 ) | 96/128 | 96/128 | 96/128 | 96/129 | |||

| THERMAL SHRINKAGE 24HRS (Density 128kg/m 3 ) | ≤ 3 | ≤ 3 | ≤ 3.5 | ≤ 3.5 | |||

| THERMAL CONDUCTIVITY(W/m. k) (Density 128kg/m3 ) | |||||||

| 800C | 0.15 | 0.176 | 0.160 | 0.155 | |||

| 1000C | 0.170 | 0.220 | 0.180 | 0.230 | |||

| 1200C | - | - | 0.260 | 0.31 | |||

| CHEMICAL COMPOSITION(%) | |||||||

| Al2O3 | 45-46 | 45-46 | 53-55 | 38-54 | |||

| SiO2+Al2O3 | 98.5 | 99 | 99 | 82-90 | |||

| ZrO2 | - | - | - | 13-18 | |||

| Fe2O3 | ≤ 0.4 | ≤ 0.3 | ≤ 0.3 | ≤ 0.3 | |||

- Q: Which thermal stability of clay bricks and high alumina bricks is good?

- High alumina brick is made of superfine alumina, fused corundum and fused mullite as main refractory materials. The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.

- Q: How much is the silica powder in refractory bricks.

- It's not easy to construct, also need to consider the technical and economic indexes, DH3, 1 kg silica powder replaces 1 ~ 3 kg cement, which is the reason why silicon powder was not used and spreaded in concrete in past, choose some silica power fume. In general, with the smoke escaping by special capture device for collecting and processing To determine the mixing method of silica powder, when mixing silica powder, you should find out the optimal dosage in order to obtain the best results, as the study, the content is 5% ~ 30%, H, the mixing of super high strength concrete, use same amount of silicon powder to replace equal cement to main same fluidity, Microsilica or Silica Fume, it is mainly according to the design requirements, and does not reduce the amount of cement, sand and stone to adjust the optimal dosage of water reducer, when deciding the best mixing amount of silica fume, the concrete is too sticky, most use naphthalene water reducing agent.

- Q: when to replace the worn refractory bricks in rotary?kiln?

- But also depend on the other conditions of the furnace, many aspects should be understood, not only to see the degree of wear!

- Q: The brick and ordinary clay brick which is expensive

- Of course expensive materials sintered clay brick, sintered clay brick fired common clay, shale and shale and coal gangue as raw materials by high temperature firing,

- Q: What are the main raw materials of refractory brick and runner brick?

- Category of refractory , runner brick mainly is clay brick

- Q: What to do if refractory bricks saltpeter when they are used outdoor

- Efflorescence is usually dialysised from brickwork joints, dealing with the gap is ok These white substaince inside the pan tile: Cement efflorescence efflorescence is wow cake section from light leather intestinal common disease inumiya Hua building surface, according to their different causes and manifestations, there is pan cream, white, whitening, cream, on the walls and decorative surface erosion and other names, is the change of soluble saline alkali soil, adobe, brick, cement, mortar, concrete, masonry, ceramic tile, paint and other building materials with temperature, humidity and other external environment, in a water absorption, water transfer, water evaporation process with physical and chemical changes of the original building material damage disease phenomenon, erosion degree also has the very big difference there is a common, get damp, foaming, powder, drum, hollowing, cracking, spalling, mildew and crystallization phenomenon. Cement efflorescence may have some relationship with the quality of the cement, sand, water, air, temperature, humidity, it is a common fault in building. Use cement to do the pebble shape, it also prones to the above problems: A layer of white stuff on the surface. Terms of settlement: Scrape the dust in brickwork joint, pointing again. Use special pointing agents, more resistant to corrosion, not easy to efflorescence.

- Q: What are the differences between fireclay brick and high alumina refractory brick?

- One is the high alumina, solid and hollow respectively, fused mullite as main raw material made of high-grade refractory materials, strong corrosion resistance, has the advantages of through mud treatment, good thermal shock stability. Good resistance to slag, used to build steel making furnace and glass furnace. High alumina brick is a kind of refractory material. Clay brick is also known as sintered brick, electric smelting corundum and low creep high alumina brick [1] with high grade bauxite, this kind of refractory brick's main component is AL2O3, which is suitable for large and small buildings with artificial bulk. High thermal stability. A neutral refractory material with more than 48% of alumina oxide content, clay brick has clay (including shale, molding, coal gangue and other powder) as the main raw materials, cement rotary furnace lining. The product has a small high-temperature creep, one is clay. From bauxite or other high content of aluminium oxide raw materials' forming and firing, refractoriness is above 1770 deg. High R.U.L and medium-sized hot-blast furnace is different firstly in the material, forming from drying and roasting

- Q: 1200 degrees inside the furnace, lay a layer of refractory brick, what is the temperature outside?

- except refractory brick, refractories include refractory concrete (refractory cement+aggregate), fire-resistant insulating layer (refractory cement+vermiculite powder or refractory cement + diatomaceous earth) and so on.

- Q: What is the perservation method for refractory bricks used for cement kiln?

- The place should be dry and ventilated. Remember that the packaging can't be damaged. If is not used for a long time, put desiccant next to the bricks. Then have thermoplastic packaging again, it won't get damp. Under normal circumstances, it can be stored for 3-5 years and won't be hairy

Send your message to us

Fireclay Brick Ceramic Fiber Blanket Refractory Blanket 1260C HP

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 225 roll

- Supply Capability:

- 31500 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords