Ceramic Fiber Blanket for Petrochemical Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

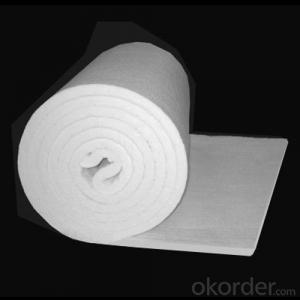

Ceramic Fiber Blanket for for Petrochemical Insulation

Composite of Ceramic Fiber Blanket for Petrochemical Insulation

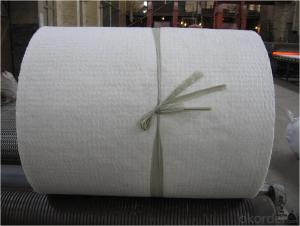

Ceramic Fiber Blanket for Petrochemical Insulation is made from high quality clay, high

purity alumina and silica oxides by spun or blown process.

Types of Ceramic Fiber Blanket for Petrochemical Insulation: ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products used different materials. Performance of Ceramic Fiber Blanket for Petrochemical Insulation also has difference, and they are suitable for different working temperatures.

Main Features of the Ceramic Fiber Blanket for Petrochemical Insulation

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Application of Ceramic Fiber Blanket for Petrochemical Insulation

◆Petrochemical process heater refractory fiber lining

◆General furnace backup insulation

◆Heat treating furnace or intermittent(shuttle) kiln hot face lining

◆Electrical insulator

◆Heat seals for kiln car or furnace door

◆High temperature acoustic

◆Fire protection

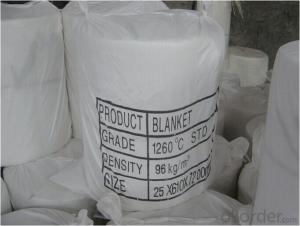

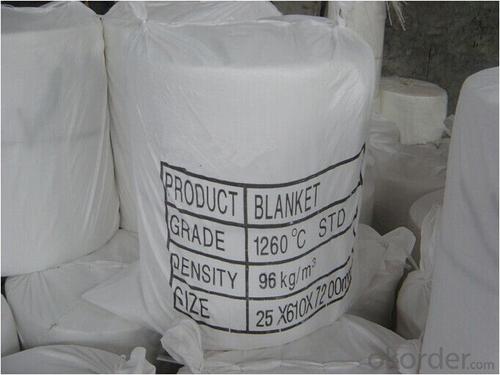

Ceramic Fiber Blanket for Petrochemical Insulation Images

Ceramic Fiber Blanket for Petrochemical Insulation Specification

Type | STD | HP | HA | HZ | |

Classification Temperature (°C) | 1260 | 1260 | 1350 | 1430 | |

Working Temperature (°C) | 1050 | 1100 | 1200 | 1350 | |

Color | Spotlessly white | spotlessly | spotlessly | spotlessly | |

white | white | white | |||

Density (kg/m3) | 64,96, | 64,96, | 64,96, | 64,96, | |

128,160 | 128,160 | 128,160 | 128,160 | ||

Shrinkage on heating (%) | ≤3 | ≤3 | ≤3.5 | ≤3.5 | |

(24 hours, density as 128/m3) | (1150°C) | (1250°C) | (1300°C) | (1350°C) | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.15(800°C) | 0.176(800°C) | 0.18(1000°C) | 0.23(1000°C | |

0.17(1000°C) | 0.22(1000°C) | 0.26(1200°C) | 0.31(1200°C) | ||

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | |

(density as 128kg/m3) | |||||

Chemical | AL2O3 | 45-47 | 45-46 | 53-55 | 38-54 |

composition | AL2O3+SIO2 | 98.5 | 99 | 99 | 82-90 |

(%) | ZrO2 | - | - | - | 10-18 |

FAQ of Ceramic Fiber Blankt for Petrochemical Insulation

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can U accept the detective of the third-party verification company ?

A:YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

- Q: I know that vampires don't exist (although I must say I'm interested in vampiric lore and mythology), but I'm just curious if one can survive just by drinking bloodIt seems like blood has all elements, which our metabolism require but I think I'm wrong and there have to be also some digestive problems (which?).

- No,one cannot survive just by drinking human blood and for many reasons including: 1Human blood is a specialized fluid primarily used for transporting oxygen, nutrients, etcIt is not an accurate representation of the chemical makeup of the human body.We require all sorts of vitamins, minerals and chemical fuel that are in short supply in bloodYou'd end up with severe potassium deficiency (you'd need to drink 10 gallons of blood per day to get your recommended daily allowance of potassium) as well as deficiency of all the fat-soluble vitamins2Even a small amount of blood in the stomach will make a person throw upThis is why bloody noses or certain injuries can cause people to vomit-they've inadvertently swallowed blood3Iron poisoning can even be a problem4.You'd become wildly constipated (complete lack of fiber and clotting nature of the blood), which can also kill you5.May also lead to rapid dehydration and electrolyte imbalance leading to cardiac arrhythmia and death.

- Q: I'm crocheting a dog for someone and I'm trying to make it look like her dogHer dog has a lot of little black spots (to small to crochet)I heard you can use fabric markers.What brand fabric markers?Can you use regular Sharpies?Thank you for any advice

- Cotton, cotton and extra cottonthank you for asking :-) And rayon, too ~ it looks like cotton and hangs superlook at We Be Bop for wild rayon topsi've got have been given one in all their patchwork button-united statesthat is super as an 'over shirt' with tank tops and skorts, and a pair caftans that look surprising with capris for summer time casual yet sorta dressy activities(purely went on OKorder to determine what they have have been given ~ no longer that i want extra outfits:-) in elementary terms have been given a number of that faux stuff for actual gown up activitiesyou be conscious of, the poly blends.

- Q: thermal paste (Arctic Silver ceramic) After reassembly, I fired it upIt ran fine at stock ( 2.5ghz)After 3 days at stock speed to let the paste set, I started stepping it upEventually getting a stable run ( though pretty hot) at 3.7 I turned it down to 3.33, the speed I normally run it at in the summerNow the question Before this process at 3.33 I idled at around 29 C and under heavy load peaked at around 60 Since the rebuild, I am idling at around 40 but even under hours of heavy load I am peaking at 52Can anyone explain to me, why this paste seems to preform poorly (in comparison) under light load, but better under heavy load? Is this typical? Could it be related to the marriage of heat sink and chip rather than the paste ( personally I doubt that, as it should get worse under load.), etcAny thoughts( the one hard ware difference with the reassembly is a more efficientt corsair PSU, ( 80 plus) replacing a generic one.)

- Try home depots website and type in insulation kitsThey show many productsI have actually installed insulation 12 years ago in walls and ceiling and they did not have a kit per se however it was really easy, just cut to size and nail upAt the time there were a few types to choose fromSingle foil backed (I used) and the more efficient 2 foil sided however this is more expensiveHope this helps

- Q: In your opinion what’s negative about using expanding foam for insulation?Currently I’m using fiber batts, R-19 and R-30 and in some places they don’t fit right or don’t fit at all in small spacesI’m concern that foam would make it hard during future repairs, specially electricAnd if there is an arch in wiring it could cause fireAnyways, thanks for advice.

- Call the Super and see if there is any opening in the bottom where you can checkIf not then you would have to call the Elevator Repair person.

- Q: i am wanting to buy some bamboo needles and need a little adviceshould I look for needles that are carbonized or will they be soft and harder to work with? or are waxed needles the way to go? i read that lacquered needles can have a lot of imperfectionsif anyone has any recommendations, they would be appreciated.

- It rather depends on what fiber you plan to knit with, tooBamboo and wood needles tend to have more tooth or grab to them with the yarn and are best for plant and man-made fibers, rather than animal fibers (other than silk)The cheapest ones tend to split and splinter, though, and bamboo splinters are wicked sharpYour best bet is to buy a pair of the style you prefer (personally, for bamboos I'd suggest Clover or, if you have the money, Addi Naturas) as the best knitting and smoothest needles.

- Q: woven fabric ,adft

- eat breakfast there have been so many studies done that show that people who eat breakfast lose more weight

- Q: I have gotten a used dish and it has no markings on the bottomHow can I tell if it is safe for baking? It is shiny everywhere but the bottomIt is quite large, is round and looks like it would be a baking dishHow do I know?

- Hard to tell from the description but here are some suggestions Some pottery can withstand more shock than others Reduce thermal shock by starting in a cold oven away from the elements When removing the hot dishplace on a folded towel EDIT - I know a number of people that make ceramic casseroles intended to go in the oven say to start in a cold ovenThe cooking time needs to be increased A reasonable increase is 5 to 10 minutesDepending on what you are doing like a slow roasted dish or a oven baked stew this would work well A lot of glazes for food should also be safe for baking as long as it is around 400 degrees Farenheit I have mixed glazes and bought mixed glazes - most are deliberately food safe I was told by several people to start in a cold ovenThere are special clay that can withstand more stress but when in doubt be carefulOne of the people makes and bakes in her piecesShe has some problems with thermal shock herselfThis is the best advise I can giveThe piece could still break even taking thes precautionsCeramic is similar to glass if it gets a sudden temperature change it can crack or shatter

- Q: just types and methods people used for house insulation in the past 100 yearz.

- Insulation dates back to as ancient as the Egyptian civilization and the Roman EmpireCorks from cork oak trees grown in Portugal, Spain and North Africa were used to insulate pipes and roofsIn Quebec, the Ural Mountains and in South Africa, fibers from stones (asbestos) were found to have excellent heat resistant propertiesAfter World War 1, there was a growth in the insulation industry, many asbestos products, rock wool insulations, as well as diatomaceous silica products were developedIn the late 1930s, major glass making companies developed and started to sell glass foam and glass fiber insulationsThere was another growth spurt in World War 2Rock wool was the major building insulation, with cotton, wood fiber and aluminum suppliers marketing their productsDuring the 1940s and 1950s, plastic foams were being developed in EuropeStyrene foams (extruded and bead board)Then urethane were tested for insulation applications, however, not very successfulIn the 1970s, various manufacturers started trying out phenolic foam but removed it from the market due to severe metal corrosion problems.

- Q: What are the specifications of ceramic fiber rope?

- Thickness: 1.5, 2, 3, 5, 6mm. Width: 20-900mm(Nickel chromium alloy wire, stainless steel wire and glass fiber are all reinforced.) Other specifications can be produced according to customers’ requests. Asbestos products have been acknowledged to be harmful to the human body and environment in recent years, and they are prohibited from production and have limited uses in the developed countries.

Send your message to us

Ceramic Fiber Blanket for Petrochemical Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords