Centrifugal Casting Furnace roll for cold milling CAL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 10000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Brand Name: | Application: | petrochemistry | ||

| Material: | Stainless steel,Cr25Ni12 | out diameter: | 150mm | surface: | coated |

Packaging & Delivery

| Packaging Detail: | Packed by wood ,Specifications according to buyers need to order the product specifications. |

| Delivery Detail: | between one and three months |

Specifications

1 low price and high quality

2 CCS certificated

3 used in annealing line and galvanizing line

4 export to CMI

1. Materials: wear-, heat- and corrosion-resistant alloy steel

such as ZG40Cr25Ni20Si2, 1Cr18Ni9, ZGCr25Ni35Nb, ZGCr28Ni48W5 HK40, HT, HU, HH, 22H, 304, 316, super 22H, HP-Nb, More1, More2, 1.4848, 1.4855, 1.4852, 2.4879, and so on.

2.Process: body is centrifugal casted and machined subsequently

Cones will be made by static casting or precision casting

Shafts will be forged, welded and machined according to relevant drawings

3.Outer diameter: 56 to 2000mm or customized

Deflector/steering rolls: 800mm

Deflector rolls: 1200mm

Entry seal rolls: 200mm

Guide rolls: 200 and 250mm

Bridle roll: 800mm:

4. Each piece has to go through our strict inspection, PT, UT, LT, or according to customers' needs.

5. Application: the furnace roll is widely used in petrochemistry, metallurgary and steel group

annealing furnace, heating furnace and hot dip galvanizing line

- Q: How is steel used in the production of laboratory furniture?

- Steel is commonly used in the production of laboratory furniture due to its durability, strength, and resistance to corrosion. It is used to make sturdy frames for lab benches, cabinets, and shelves, providing a reliable and long-lasting support system for the equipment and materials used in laboratory settings. Additionally, steel can be easily sterilized and cleaned, making it a hygienic choice for laboratory furniture.

- Q: How is steel wire rope manufactured?

- Steel wire rope is manufactured through a process called wire drawing, where steel rods are drawn through a series of dies to reduce their diameter. These drawn wires are then laid into strands and twisted together to form a rope. The strands are usually twisted around a central core to provide additional strength and stability. The finished steel wire rope is then subjected to various heat treatments and coatings to enhance its durability and resistance to corrosion.

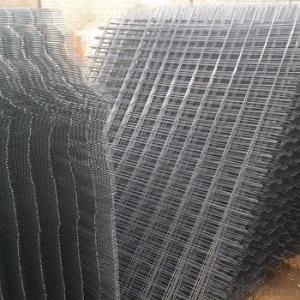

- Q: What are the applications of steel mesh?

- Steel mesh is widely used in various applications such as construction, reinforcement, fencing, landscaping, and industrial sectors. It is commonly used for concrete reinforcement, providing strength and stability to structures like buildings, bridges, and highways. Steel mesh is also utilized in fencing systems, ensuring security and safety in residential, commercial, and agricultural settings. Additionally, it is employed in landscaping projects to support plants and prevent soil erosion. In industrial settings, steel mesh is used for filtration, sieving, and separation processes. Overall, the applications of steel mesh are diverse, making it a versatile and essential material in various industries.

- Q: How are steel products used in the manufacturing of consumer goods?

- Steel products are widely used in the manufacturing of consumer goods due to their strength, durability, and versatility. They are commonly used in the production of appliances, automobiles, construction materials, packaging, and even household items like cutlery and furniture. Steel provides stability and structural integrity to these goods, ensuring their longevity and safety for consumers.

- Q: How is steel used in the manufacturing of elevator systems?

- Steel is used in the manufacturing of elevator systems primarily for its strength and durability. It is used to construct the frame, support beams, and shafts of the elevator, providing structural stability and ensuring the safe transportation of passengers or goods. Additionally, steel is used in the fabrication of elevator doors, car panels, and other components due to its excellent resistance to wear and tear.

- Q: How is steel forgings inspected for quality assurance?

- Steel forgings are inspected for quality assurance through various methods, including visual inspection, dimensional checks, and non-destructive testing. Visual inspection involves examining the surface for any defects, such as cracks or porosity. Dimensional checks ensure that the final product meets the required specifications and tolerances. Non-destructive testing techniques, such as ultrasonic or magnetic particle testing, are used to detect internal defects or irregularities. These inspection methods help ensure the quality and integrity of steel forgings before they are used in various applications.

- Q: What are the different types of steel scaffolding and support systems available?

- There are several types of steel scaffolding and support systems available, including tube and clamp scaffolding, system scaffolding, frame scaffolding, and suspended scaffolding. Tube and clamp scaffolding consists of steel tubes and clamp fittings that can be connected in various configurations to create a stable structure. System scaffolding uses pre-fabricated components and is quick to assemble and dismantle. Frame scaffolding features a simple frame structure with horizontal and diagonal braces. Suspended scaffolding is suspended from above and is commonly used for tasks such as window cleaning or painting on tall buildings.

- Q: How do steel products contribute to the construction of research laboratories and scientific facilities?

- Steel products play a crucial role in the construction of research laboratories and scientific facilities. They provide structural support and durability, ensuring the safety and integrity of the buildings. Steel beams, columns, and frames are commonly used to create large open spaces, allowing for flexible layouts and accommodating various equipment and machinery. Additionally, steel is resistant to fire, corrosion, and pests, making it an ideal choice for laboratories where hazardous materials and sensitive experiments are conducted. Overall, steel products are essential components in creating efficient, functional, and secure research facilities.

- Q: How do steel products contribute to the defense and security sector?

- Steel products contribute to the defense and security sector in several ways. Firstly, steel is widely used in the manufacturing of military vehicles and equipment, providing strength and durability necessary for combat operations. Additionally, steel is utilized in the construction of military infrastructure and facilities, such as bases and fortifications, ensuring their resilience and protection. Furthermore, steel is crucial in the production of munitions and firearms, delivering essential components for defense forces. Overall, steel products play a vital role in strengthening the defense and security sector by providing the necessary materials for robust and reliable military operations.

- Q: How are steel products used in the marine and shipbuilding industry?

- Steel products are widely used in the marine and shipbuilding industry due to their strength, durability, and corrosion resistance. They are used to construct the hull, decks, bulkheads, and other structural components of ships and offshore structures. Additionally, steel is utilized in the fabrication of equipment, such as propellers, shafts, and anchoring systems. Its use in the marine industry ensures the safety and reliability of vessels, making it essential for shipbuilding and maritime operations.

Send your message to us

Centrifugal Casting Furnace roll for cold milling CAL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 10000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords