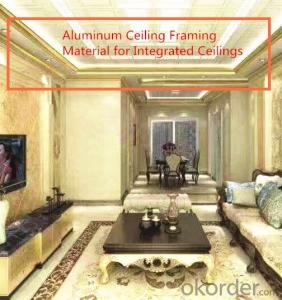

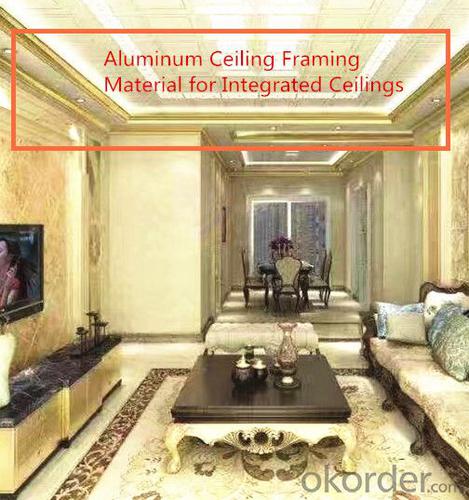

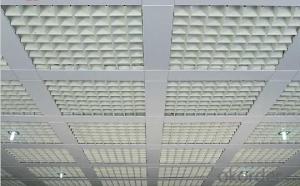

Aluminium Perforated Ceiling Singapore - Ceiling Framing Material for Integrated Ceilings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Introduction

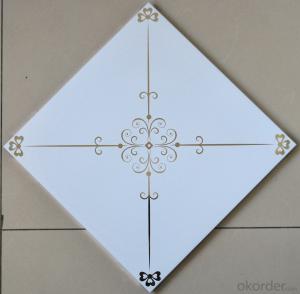

As aesthetic values evolve, wood grain effect finishing is now becoming more and more popular in the fields of architectural decoration, furniture, electronics and home appliances. Wood grain effect finishing is a special powder coating process based on the latest technology in the surface finishing.

The wood grain finished aluminum profile is a perfect integration of the excellent aluminum properties with the natural appearance of natural resources such as wood, marble, etc. It is a wonderful combination of the state-of-the-art technology and aesthetics. The products have stable quality, appealing appearance and therefore a higher value of decoration.

2. Wood Grain Effect Features

(1). Materials:

can be transferred to all kinds of substrate shapes, including sheets.

(2). Effects:

The decorative effects of pictures, text and graphs, and all kinds of natural sceneries (such as wood, marble or granite grains) can be achieved through photographic technology.

(3). Aesthetic Value:

Patterns of the most precious woods, such as oak, chestnut, cherry and walnut, can be imitated.

(4). Durability:

Excellent weathering-resistance performance, durable in all kinds of applications.

(5). Cost Savings:

Maintenance free, will resume original effect simply by regular cleaning.

(6). Environmental Friendliness:

The special decoration needs can be realized without using wood; meanwhile the products can be recycled.

(7). Fields of Applications:

The wood effect can be applied to windows, furniture, components, appliances, transportation vehicles (airplanes, ships and cars) and other decorating materials. It can be furnished according to customer requirements

3. Chemical composition

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al |

6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | 0.1 | 0.1 | 0.15 | Rest |

6061 | 0.4-0.8 | 0.70 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.15 | Rest |

6005 | 0.6-0.9 | 0.35 | 0.1 | 0.1 | 0.4-0.6 | 0.1 | 0.1 | 0.1 | 0.15 | Rest |

4. Mechanical property

Alloy | Temper | Tensile strength | Yield strength | Elongation |

6061 | T6 | ≥ 265Mpa | ≥ 245Mpa | ≥ 8% |

6063 | T5 | ≥ 160Mpa | ≥ 110Mpa | ≥ 8% |

T6 | ≥ 205Mpa | ≥ 180Mpa | ≥ 8% |

5. Anodized

Grade | Anodizing thickness | Hole scaling quality of oxide layer | |

Average thickness | Local thickness | P. Cr acid-erosion weight less method | |

AA10 | ≥10um | ≥8um | ≤30 mg/d m2 |

AA15 | ≥15um | ≥12um | |

6. Powder coating & wooden-grained

Coating thickness | Coating impress rigidity | Adhesive force of coating layer |

40-120um | Indentation hardness>80 | 0 grade

|

7.

Material | 6063,6060,6061,6005 |

Temper | T4,T5,T6 |

Surface treatment | Mill Finish,Anodized,Eletropharesis,Powder Coated, Wooden Finish, Polish |

Colour | Silver,Black,Red,Blue,or as required |

Length | ≤6m |

Shape | Round,Square,T-slot,or as per the drawings and samples |

Fabrication | cutting,drilling,punching,bending,etc |

Wall thickness | ≥0.5mm |

Package | inner plastic paper interleaving each piece profile,outer fixed by plywood, or as per your requirements |

- Q: Aluminum slab plate 300 × 300 panel lights up to the number of watts

- 300300's routine is 24W The largest words can also reach 30W drive current can be transferred Details can be asked on the 1688 platform, China Green Fu photoelectric

- Q: Most of their prices include installation fees, right? Is there a price of tens of dollars now? Less than 100 yuan per level are false, right? thank you all

- No, aluminum buckle is one of the integrated ceiling.

- Q: The top of the kitchen ceiling of the ceiling of the ceiling

- Fine work, take the first piece of plastic plate with a plastic sucker (or tape) to take, be careful to get the buckle plate is not easy to install.

- Q: How much is the price of an inch? Pack material

- According to the brand and thickness, specifications, etc. to determine, generally the cheapest also more than 60 yuan, the thickness of only 0.4mm less than.

- Q: Integrated ceiling aluminum slab plate for you

- Will remove the buckle board, homeopathic will need to replace the buckle plate installed back on it!

- Q: Can the aluminum plate be cut and installed?

- Kouban can be cut to install, the buckle is stuck in the metal card above the no problem, the direction of the cut is best horizontal, vertical a little problem.

- Q: Aluminum buckle board a side of the edge of how fixed

- Aluminum-plastic plate Construction process: keel layout and elastic line → installation and leveling keel → installation of aluminum-plastic plate → trim sealing. 1), the elastic line: to determine the elevation control line and keel layout line, if the ceiling has a variable height, the corresponding part of the variable section should be determined, and then along the elevation line fixed angle aluminum. 2), to determine the keel position line: According to the size of aluminum-plastic panels and ceiling Aluminum plate is made of aluminum alloy plate, through the open material, shear angle, molded, aluminum plate surface using a variety of different coating processing to get a variety of aluminum plate products, aluminum slab plate, the most important two Type, one is home improvement integrated Lvkou Ban, the other is the engineering Lvkou Ban, home-made aluminum slab board mainly to roll and frost the main series of two, with the development of home improvement integrated aluminum plate has been Variety of different processing technology are used to them, such as thermal transfer, glazed, ink printing, mirror, 3D and so on series is the most popular in recent years, home improvement integrated aluminum slab plate, home improvement integrated aluminum plate is Board surface fancy, service life, board advantage and so on to obtain market recognition, engineering aluminum slab board is commonly used roller coating, powder coating, film, scrub and other surface coating, the surface is relatively simple, the color is solid , Of which milky white is the most expensive to use aluminum slab plate, engineering aluminum plate to buy the most important depends on the coating, coating color protection is the primary consideration, the coating to maximize the life to ensure that the owners interest.

- Q: Why kitchen ceiling is not recommended with plastic buckle plate? Why can not the aluminum buckle kitchen with a hole in the bathroom can be used with holes?

- Bathroom and kitchen ceiling can not use holes with aluminum plate

- Q: The top of the kitchen is decorated with an aluminum plate or a good gypsum board

- Kitchen bathroom should be used aluminum plate, that is, integrated ceiling! Aluminum is suitable for the kitchen is not beautiful, the greater use is anti-fumes, pollution, corrosion, easy to clean up! Toilet selection integrated ceiling is the best choice for the internal space, waterproof and strong, for the toilet bath and other electrical operation to provide better protection!

- Q: Which out of the color, better?

- The effect is good for aluminum-plastic panels Most of the billboards are made of aluminum But also available acrylic ah better effect of smooth gloss and good

Send your message to us

Aluminium Perforated Ceiling Singapore - Ceiling Framing Material for Integrated Ceilings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords