Catwalk for Ringlock System Metal Planks with Hook 500*50*1.5*1200mm CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

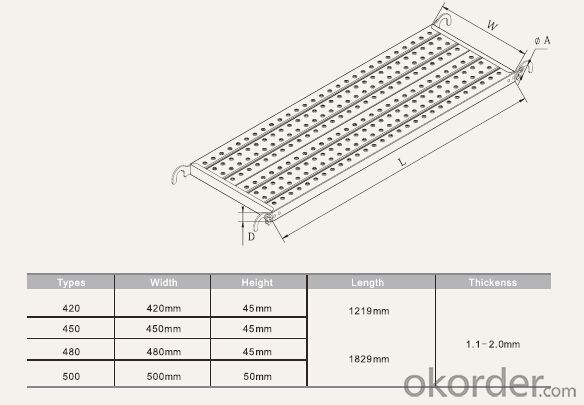

Quick Details of Catwalk for Ringlock System Metal Planks with Hook 500*50*1.5*1200mm

Material :Q235/Q345 carbon steel

Surface treatment :Hot dip galvanized, pre-galvanized

Thickness :1.0mm,1.1mm,1.2mm,1.5mm,1.8mm

Length :900MM/1200MM/1500MM/2000MM/2500MM/3000MM

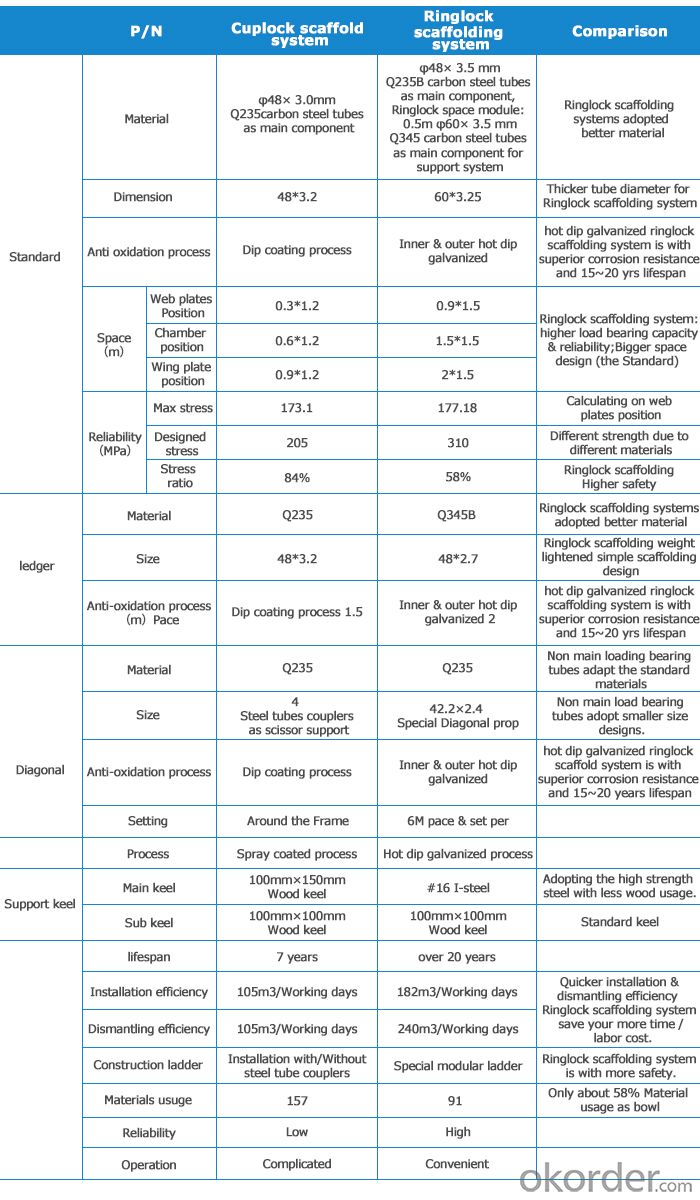

Descriptions of Catwalk for Ringlock System Metal Planks with Hook 500*50*1.5*1200mmRinglock scaffolding and ringlock support system are popularly used in building construction, external scaffolding, cast-in-situ beam, formworks support, canopy frame, bridge & tunnel, stage construction applications and welcomed by building construction companies, construction & decoration companies, leasing companies, media & advertising companies and other users。

Our patented Ringlock scaffolding and Ringlock support system with surface galvanizing process provided the buyers with higher safety & benefits. 7000 tons annual output.

The strong ringlock scaffold system is with 2~3 times installation & dismantling efficiency higher than the cuplock scaffolding system, but only with half steel usage and 75% investment cost.

Our low cost & high benefits Ringlock scaffolding system with hot dip galvanized surface treatment are easy to installation & disassembly.

Our Ringlock Scaffolding and Ringlock support system with 200 KN high loading bearing capacity are buyers’ safe & professional choice.

Patented R&D and production; Single personal installation with a hammer only. Greatly saved the steel usages compared to steel tube with couplers.

Catwalk Details:

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Im hoping to get an industrial/scaffold piercing done at the very beginning of the summer holidays.Is it possible that they can be pierced with 2 separate pieces of jewellery rather than one bar.Also would it be healed in time to take it out once the holidays are over (6 weeks)??Please help??!?Thanks x

- nope! Cartilage piercings take about a year to fully heal up. Yes, you can get 2 separate bars, but let the piercer know thats what you want. Industrials are VERY hard to take care of. Make sure to listen to EVERYTHING the piercer says!

- Q: What's the film where gene Kelly dances on scaffolding? And at a gym?

- I think it's Living in a Big Way.... I could be wrong...

- Q: I would like to ask how much scaffolding steel prices, scaffolding steel pipe use what are the requirements?

- Scaffolding steel pipe1, set up a high-level scaffolding, the various materials used must meet the quality requirements.2, the foundation must be firm, before the erection of the calculation, to meet the load requirements, and according to the construction code set up, do drainage measures.3, scaffolding erection technical requirements shall comply with the relevant provisions of the code.4, we must attach great importance to a variety of structural measures: scissors, pull nodes, etc. should be set according to requirements.5, the level should be closed: the first step, every step or two, covered with planks or hand foot fence, scaffolding to laying along the long, joints should be overlapped in the small bar, do not appear short board. And in between in the pole and the wall every four steps long laying safety bottom fence.6, vertical closure: from the second step to the fifth step, each step required in the outer row of pole side door set like baluster 1.00m high and block feet or to set up protective net, rod (net) and the vertical rod fastened; more than fifth steps in a protective railing, should all the safety fence or security legislation net; in the street or densely populated areas, should be from the second step, the safety fence or outside of all network security legislation.

- Q: Is it easier to build a disc scaffolding system than a bowl buckle scaffold?

- It is widely used in bridge engineering, tunnel engineering, workshop, elevated water tower, power plant, oil refinery... Support design and special plant, is also applicable to overpass span scaffolding, storage shelves, chimney, water tower and indoor and outdoor decoration, large concert stage, the background frame, stands, balcony frame, stairs, other party system, stage setting, sports watch station project.

- Q: Construction scaffolding right angle fastener, rotary fastener, butt fastener weight? There are more than one meter steel pipe?Thank you!!!

- Weight: 48kg above 3, single piece weight in 20Kg or so, easy to carry and construction operation. 4, the installation and removal of only bare handed, greatly improved the efficiency of the door scaffolding installed than the fastener steel tube fast 1/2 time, faster than bamboo scaffolding 2/3 time. 2 the maximum weight of a single piece is not more than 20 kg, so lifting, assembling and disassembling and transportation are convenient

- Q: scaffolding piercing.. do they hurt? and how much are they in england? thanks x?

- Yes, they hurt, quite a lot. But how rad they look outweighs the pain. :D

- Q: Can anyone give a very brief description on all three scaffold scenes in The Scarlet Letter?

- concentration your interest on who's on the scaffold, how they react to the regularly occurring public shaming, and what the reader learns with regard to the character from examining the define of them on the scaffold.

- Q: Scaffold removal should comply with those requirements......

- Demolition safety requirementsThe removal order should be 1 layers from the top down, at the same time no homework.2 remove the frame rods and connectors, springboard and other materials, should be used in rolling, prohibited throw down. The foot lever and remove the plate have been demolished, should be disposable.3 all the pieces of the wall should be removed from the scaffold layer by layer, it is strictly forbidden to take the whole or a few layers of the demolition of the wall and then dismantle the scaffolding; the demolition of the height difference should not be greater than two steps, such as the height difference is greater than the two step should be added to strengthen the wall.4 when the scaffolding removed to the lower part of the last long steel pipe height, according to the needs of the site in the appropriate position to take temporary support reinforcement, after the demolition of the wall.

- Q: He pushes a can over the scaffold at 15 meters and it takes 3.25 seconds for it to land.I keep doing the problem over and over. the Correct answer is 20.5 m/s, however I keep arriving to the solution of 17 m/s. I solved it by doing Vf^2 = Vi^2 + 2adwhere the initial velocity is zero and the acceleration is -g. I made my coordinate system so that down is negative in which the distance will be negative. This however, did not give me the correct answer. Am I right or is the book right?

- The initial velocity is not zero since the scaffold is moving upward when the can gets pushed over. And final velocity, vf, does not represent the speed of the scaffold (if that is what you're trying to solve). y = (vo)(t) - (1/2)gt? 15 m = (vo)(3.25 s) - (1/2)(9.81 m/s?)(3.25 s)? vo = +20.5 m/s

- Q: Fastener type steel pipe scaffold composed of which components?

- Reference to "construction safety of steel tubular scaffolding safety technical specifications" JGJ 130 - 2011, 8, page parts3.1 steel pipe3.1.1 scaffolding steel pipe should be used in the current national standard "straight welded steel pipe" GB/T13793 or "low pressure flowQ235 steel pipe for the welded steel pipe used for conveying body; the steel quality of the steel pipe shall be GB/T3091In accordance with the existing national standard "carbon structural steel" GB/T700 Q235 steel provisions.3.1.2 scaffolding steel pipe should be used 48.3 * 3.6. The maximum quality of each steel pipe shall not be greater than25.8kg.

Send your message to us

Catwalk for Ringlock System Metal Planks with Hook 500*50*1.5*1200mm CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords