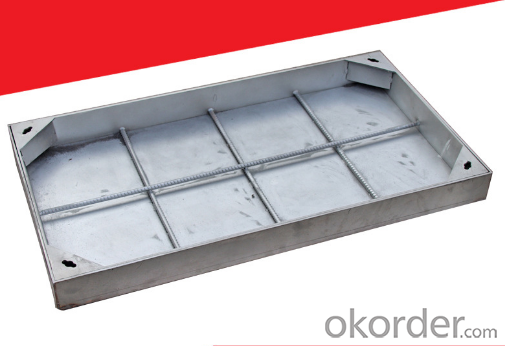

Casting Ductile Iron Manhole Covers B125 D400 with Competitive Price in Hebei

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type: round type and Square type, triangle

4) Sand casting

5).we can produce as per customers' drawings

6)ISO9001:2008

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| PCE300 | C250 | 200×200 | 300×300 | 35 | 8 |

| PCE400 | C250 | 300×300 | 400×400 | 35 | 13 |

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1.Can I get free samples?

A: Yes, we can provide you the free sample, but you need to bear their own delivery costs.

2.Can I request to change the form of packaging and transportation?

A:Yes,We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

3.Can I request to advance the shipment?

A: It should be depends on whether there is sufficient inventory in our warehouse.

4.Can I have my own Logo on the product?

A: Yes, you can send us your drawing and we can make your logo, but you have to bear their own the cost.

- Q: How to calculate the price of casting parts?

- According to the complexity of the workpiece, material and casting requirements and process yield

- Q: What are the requirements for casting steel castings?

- 2, the plane should be placed on the following.3, thin parts should be placed below.

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angle

- Q: Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- Annealing is needed to eliminate stress and refine grain

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- The molten iron (molten iron, scrap steel, scrap casting, iron alloy) is melted into cast iron by means of an electric furnace or cupola, and is poured into a casting.

- Q: How to cast iron and wrought iron collocation

- 2, listen: Pig beating sound boring, wrought iron beating sound loud.

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q: What kind of flaw detector is better for casting parts?

- Casting using the detector test, you must first determine the detection process, such as the detection of surface and near surface crack defects, such as casting, recommended by CYD-3000, or CYD-5000 mobile magnetic testing machine for testing.

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- Tangshan Yongding automobile spare parts factory also give a lot of supply, casting factory of Tangshan n to the car enterprises casting wheel gearbox etc.The team of casting experts welcome you to ask questions and accept questions!

- Q: Heat treatment process and purpose of casting parts

- Natural aging (also known as Chang Hua): lost in the open, the sun and rain, can have experienced years of wind and frost.

Send your message to us

Casting Ductile Iron Manhole Covers B125 D400 with Competitive Price in Hebei

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches