Monolithic Refractories for Electric Power - Refractory Plastic Castable

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

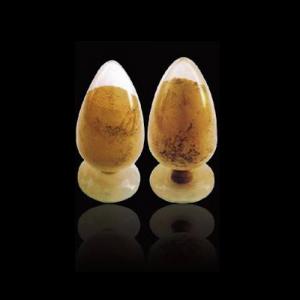

Supported by our robust infrastructure, we offer a range of phosphate bonded castables/plastic castable that are available in different specifications. Our range is widely used in various industries such as cement, steel, furnaces, foundries etc. Manufactured using best grade raw material, our range is widely demanded by our clients owing to its superior quality and excellent resistance to heat & temperature.

The raw material of plastic castable is high alumina clinker, corundum, mullite, and silicon carbide as aggregate or powder, and combined different binder, and admixture.

Characteristics of plastic castable:

1. Convenient for construction.

2. Good plasticity.

3. Excellent Wear Resistance.

Technical Data of Plastic Castable :

| Items | Index | NO. | |

| KS-1 | KS-2 | ||

| Al2O3% | 75 | 60 | |

| Bulk density (g/cm3) | 1000°C×3h | 2.65 | 2.35 |

| Cold Crushing Strength(Mpa) | 110°C×24h | 45 | 35 |

| 1000°C×3h | 85 | 70 | |

| Modulus of Rupture(Mpa) | 110°C×24h | 6 | 4.5 |

| 1000°C×3h | >11 | >9 | |

| Linear change after buring % | 1000°C×3h | ±0.5 | ±0.5 |

| Wear Resistance cm3 | 1000°C×3h | 5 | 6 |

| Thermal shock resistance(times) | 1000°C water cooling | 30 | 25 |

- Q: What is the construction method of ladle casting material? Where is the introduction of casting technology for unshaped refractories?

- Supply and demand imbalance, the industry must adjust the strategy, innovation has become a trend, at this point, network marketing strategy has been quietly probe.

Send your message to us

Monolithic Refractories for Electric Power - Refractory Plastic Castable

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords