Monolithic Refractories for Electric Power:Alumina Spinel Castable for Ladle and Tundish

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

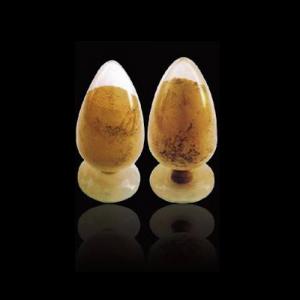

Made as per international standards, CMAX alumina spinel castable for Ladle and Tundish is known for its excellent corrosion resistance, long operating life and high refractoriness. Further, these can be provided in different specifications as required by the clients.

Feature

Excellent corrosion resistance

Long operating life

High refractoriness

Application

Ladle and Tundish

Technical Data

Item | Alumina Spinel Castable for Ladle and Tundish | |||||

Al2O3 | % | ≥ | 72 | |||

MgO | % | ≥ | 10 | |||

CaO | % | ≤ | — | |||

SiO2 | % | ≤ | 9 | |||

SiO2+ Fe2O3+ Al2O3 | % | ≤ | ||||

Bulk density ≥ | g/cm3 | — | ||||

C.C.S. (MPa) ≥ | 110℃×24hrs | 90 | ||||

1500℃×3hrs | 100 | |||||

M.O.R.(MPa) ≥ | 110℃×24hrs | 11.5 | ||||

1500℃×3hrs | 11.5 | |||||

Refractoriness (℃) ≥ | — | |||||

Grain size (mm) ≤ | — | |||||

Permanent linear change | 1500℃×2hrs | -0.2~0.35 | ||||

1500℃×3hrs | — | |||||

Life time (hr) | — | |||||

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

- Q: What is the construction method of ladle casting material? Where is the introduction of casting technology for unshaped refractories?

- Now the situation is, Hua Heng refractories factory workers wages rose, financial costs are rapid growth, so the refractory products price index continues down.

Send your message to us

Monolithic Refractories for Electric Power:Alumina Spinel Castable for Ladle and Tundish

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords