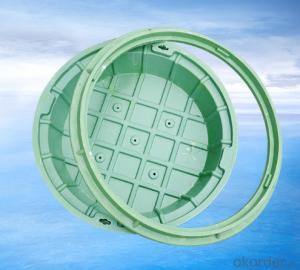

Cast iron Concrete Manhole Covers, Ductile iron Manhole Cover in Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1) Material

a) Ductile Iron GGG500-7 & 400-12

b) Grey Iron GG20

2) Designs.

a) EN124 A15, B125, C250, D400, E600 and F900

b) A60005 for casting design

c) Major standards designs available

d) As per customers' drawings or samples

3) Process

c) Molding boards

d) Green sand with hand molding

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| PBC400 | B125 | 300×300 | 400×400 | 30 | 18 |

| PBC500 | B125 | 400×400 | 500×500 | 35 | 17 |

| PBC550 | B125 | 450×450 | 550×550 | 35 | 21 |

Advantages:

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life

(at least 30 years). The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than. Contain no metal and no recovery value, anti-theft.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our products: produced by the hydraulic Press. Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

5. Our price: we are the factory, we provide the most competitive price with good quality, and large order quantity will get big support by us!

6. Professional technical support with free charge.

Delivery Time

30-45 days depends on the demand quantity

FAQ

1. Are you a trader or manufacturer ?

We are professional manufacturer for more than 30 years .Our company products including ductile cast iron rain grate,nodular cast iron manhole covers,ductile iron anti-theft covers,urban greening tree pit cover plate etc.

2. What is your products advantage ?

A.All kinds of size as customer's requirements;

B.Small quantity trial order is welcome

C.Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D.Quality control and Promtly delivery

E.Good after sales servic

- Q: How to calculate the price of casting parts?

- Cost of raw materials + electricity (fuel) costs + workers' wages + managers' wages + transport costs + raw materials burned + accessories costs + equipment maintenance depreciation costs + management fees + tax. The most convenient, the raw material market price plus 2000 yuan, plus you want profits on the line.

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- Because the grinding machine is layer by layer. And the material inside the casting is not completely uniform.

- Q: What are the requirements for casting steel castings?

- 4 thickness, most should be placed above the.5 and try to reduce the number of.6, the sand core should be used in classification of flat surface

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- 2 improve the crystal structure, enhance the formation and stability of spherical carbon crystal;Forgings are generally stress bearing members, and most of them are made of high strength medium carbon steel (alloy), which is formed by forging and fine crystalline. After the shell is annealed or quenched and tempered, the mechanical properties of the shell are more superior, and it has better strength and better elasticity;Welding materials.

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: What method of casting does not rust? I think the sample is like oil

- Close to the solder, and slowly dissolve is hot melt double-sided adhesive, otherwise it is oily double-sided adhesive.

- Q: What are the casting parts processing engineering?

- According to the classification of process methods, sand casting and special casting.

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- The finish of reaming depends on the material and the sharpness of the reamer, as well as the speed and speed of the top and bottom. Marine machine tool

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Our country has a national standard for casting tolerance levels. This national standard applies to you in malleable iron, grey cast iron, and ductile iron.

Send your message to us

Cast iron Concrete Manhole Covers, Ductile iron Manhole Cover in Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords