Carbon Steel Pipe Fittings FLANGED PIPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

pipe fitting elbow

Certificate:ISO:9001-2000

New material,completely meet asme and din standard

Best price

1. type: AISI ASTM A234 WPB BW Con Elbow

2. Size: 1/2"-48"(1/2"-24"is seamless and 26"-48"is welded)

3. Wall thickness: sch10-160, STD, XS, XXS

4. Material: A234WPB, A420WPL6, A420WP5, WP11, WP12, WP22, etc

5. Welding line: seamless

6. Angle of bend: 30, 45, 90, 180degree

7. Bending radius: SR, LR

8. Standard: ANSI B16.9, JIS, SB, DIN, GB

9. Surface treatment: black paint, vanis paint, black rust-proof oil,

transparent oil, hot galvanizing

10. Application: petroleum, electricity, chemical, natural gas, metallurgy,construction,

shipbuilding and other fields because of its high pressure, high temperature, etc

11. connection: welding

12. technics:forged

13.Certificate:ISO9001 - 2000, CE, SGS, etc.

14. packaging: wooden case, pallet, container or in accordance with the

requirement of customers

15. Principle: quality fist, customer first, credit first

16. payment: L/C T/T

17. delivery time: 7-25 days after payments

18. Notes: the bevel can be made in accordance with the special requirements

of the customers

19. Others: we can also produce the products according to the requirements

of the customers

The main production:

1. PIPE FITTINGS: elbows, tees, bends, reducers, cap, flanges and sockets etc.

2. PIPE: bult welded pipes, seamless pipes, threaded pipes, etc.

We sincerely welcom customers at home and abroad to visit us and seek common development.

- Q: What are the properties of high-strength steel for structural applications?

- High-strength steel for structural applications possesses properties such as exceptional strength, excellent toughness, and superior corrosion resistance. It can withstand heavy loads and external forces while maintaining its structural integrity. Additionally, high-strength steel exhibits a higher yield strength and ultimate tensile strength compared to regular steel, allowing for the creation of lighter and more efficient structures.

- Q: What are the different types of steel roofing materials?

- There are several types of steel roofing materials available, including galvanized steel, galvalume steel, zincalume steel, and stainless steel. Each type offers different properties and advantages, such as corrosion resistance, durability, and aesthetic appeal.

- Q: What are the different types of steel gratings and walkways available?

- There are several types of steel gratings and walkways available, including welded steel gratings, press-locked steel gratings, and riveted steel gratings. Additionally, there are various options for surface treatments, such as galvanized or painted coatings, to enhance durability and resistance to corrosion. These steel gratings and walkways can be customized in terms of size, shape, and load-bearing capacity to suit specific industrial or architectural requirements.

- Q: How is steel rebar used in concrete construction?

- Steel rebar is used in concrete construction to provide reinforcement and strength to the concrete structures. It is typically placed within the concrete forms before pouring, forming a framework that helps to distribute the load and prevent cracking or failure. The rebar enhances the tensile strength of the concrete, allowing it to withstand greater forces and improve the overall durability and longevity of the structure.

- Q: What are the different types of steel coatings for corrosion prevention?

- There are several types of steel coatings available for corrosion prevention, including galvanized coatings, metallic coatings, organic coatings, and ceramic coatings. Galvanized coatings involve applying a layer of zinc to the steel surface to provide a protective barrier against corrosion. Metallic coatings, such as aluminum or zinc-aluminum, offer excellent corrosion resistance due to their sacrificial properties. Organic coatings, such as epoxy or polyurethane, create a protective film on the steel surface to prevent contact with corrosive elements. Ceramic coatings, like porcelain enamel or vitreous enamel, offer high resistance to corrosion, chemicals, and extreme temperatures. Each type of coating has its advantages and suitability for specific applications.

- Q: What are the different types of steel reinforcements used in construction?

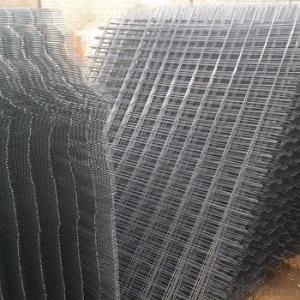

- There are several types of steel reinforcements used in construction, including rebar, wire mesh, and steel fibers. Rebar, short for reinforcing bar, is a common choice and is typically made of carbon steel. It is used to provide strength and stability to concrete structures. Wire mesh, made of interconnected steel wires, is used to reinforce concrete slabs and walls. Steel fibers, on the other hand, are small, thin strands of steel that are added to concrete to enhance its strength and durability. These different types of steel reinforcements are used depending on the specific needs and requirements of the construction project.

- Q: What are the different types of steel shelving systems?

- The different types of steel shelving systems include boltless shelving, rivet shelving, wire shelving, and pallet racking systems.

- Q: How is steel used in the construction of amusement parks and entertainment venues?

- Steel is commonly used in the construction of amusement parks and entertainment venues due to its strength, durability, and versatility. It is used to build roller coasters, ferris wheels, ride structures, and various other attractions. Steel provides the necessary support to ensure the safety and stability of these structures, allowing for thrilling and enjoyable experiences for visitors.

- Q: What are the different types of steel meshes and their applications?

- There are several different types of steel meshes with various applications. Some common types include welded wire mesh, expanded metal mesh, and woven wire mesh. Welded wire mesh is frequently used in construction, agriculture, and fencing due to its strength and durability. Expanded metal mesh is often utilized for grating, walkways, and filters due to its high load-bearing capacity and ventilation properties. Woven wire mesh is commonly used in industries such as mining, filtration, and security due to its versatility and ability to withstand heavy-duty applications. Overall, steel meshes serve diverse purposes and are chosen based on their specific properties and intended applications.

- Q: What are the properties and characteristics of stainless steel?

- Stainless steel is a corrosion-resistant alloy that contains a minimum of 10.5% chromium, which forms a passive layer on the surface, preventing further oxidation. It is known for its high strength, durability, and heat resistance, making it suitable for various applications. Stainless steel is also easy to clean, non-magnetic, and has excellent hygiene properties, making it ideal for use in the food and medical industries. It is available in different grades, each with specific properties, such as increased corrosion resistance or improved strength, to suit different applications.

Send your message to us

Carbon Steel Pipe Fittings FLANGED PIPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords