CAMX Co-rotating Conical Twin-screw Plastic Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

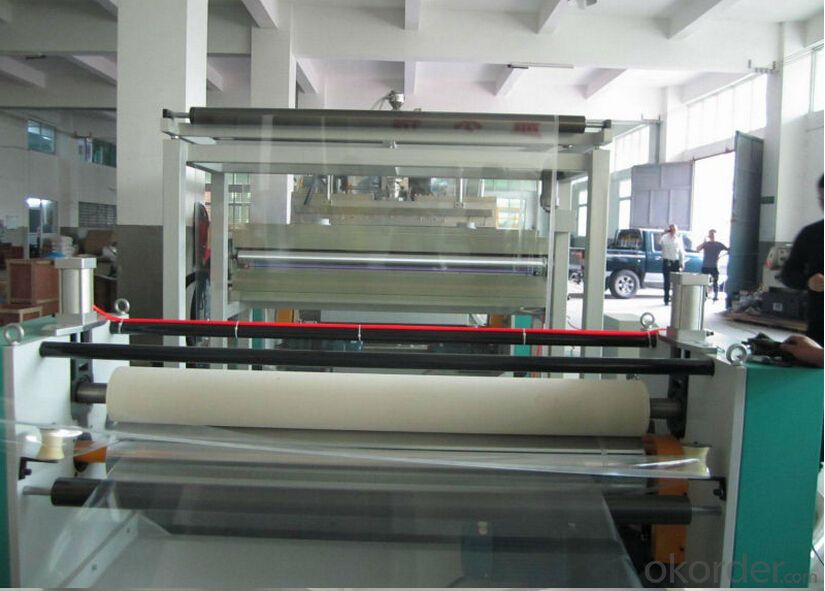

Introduction

Good Quality PEVA Car Cover Film Extruder uses LDPE, PP, EVA, PEVA, LLDPE, HDPE, TPU as raw material, and then laminates the extruded film onto various kinds of substrates, such as nonwoven fabric, BOPP, BOPET, BOPA, and paper etc. The final products are widely used for hygienic and medical products, the packaging of food, chemical industry, electrical products and metallurgy etc.

Packaging & Delivery

| Packaging Detail: | Best Sea transportion package to avoid damagement |

| Delivery Detail: | 60 days |

In order to the customer’s technics requirement for the conveter belt,CNBM successfully develops serials conveyer belt cover extruder and relation mould,it can be molding for the pvc belt’s surface,adjust the thickness of the cover,leave out the others.This extruder install on the left and right,have good plastic,high output,low power and the high design for the produce

Technical parameters

| Model | Screw Diameter | Screw L/D ratio | T Die Width | Film Width | Film Thickness | Liner Speed |

CMAX-LY-1250 | 90mm | 36:1 | 1250mm | 1000mm | 0.02-0.3mm | 30-80m/min |

CMAX-LY-1900 | 110mm | 36:1 | 1900mm | 1600mm | 0.02-0.3mm | 30-80m/min |

CMAX-LY-2300 | 120mm | 36:1 | 2300mm | 2000mm | 0.02-0.3mm | 30-80m/min |

CMAX-LY-2600 | 135mm | 36:1 | 2600mm | 2300mm | 0.02-0.3mm | 30-80m/min |

Applications:

1) Hygieneproducts: sanitary napkin, lady pad, baby diaper, medical surgical gown, pet cushion, disposable underpad and etc.

2) Daily necessities: raincoat, umbrella, tablecloth, western style suit cover, glove, apron, bath curtain, bath hat and etc.

3) Packaging: computer cover, electric appliance cover, shoes cover, cosmetic soft package, shopping bag, gift bag, document folder, file cover and etc.

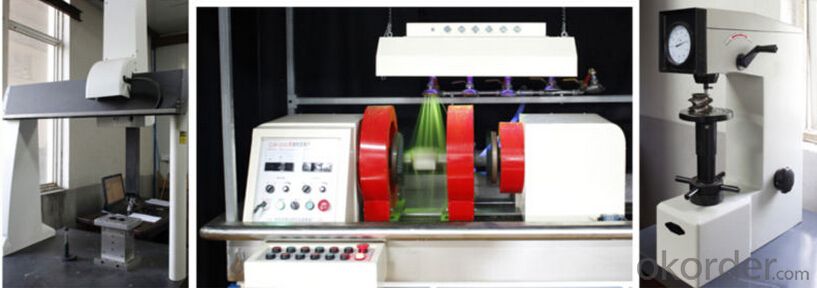

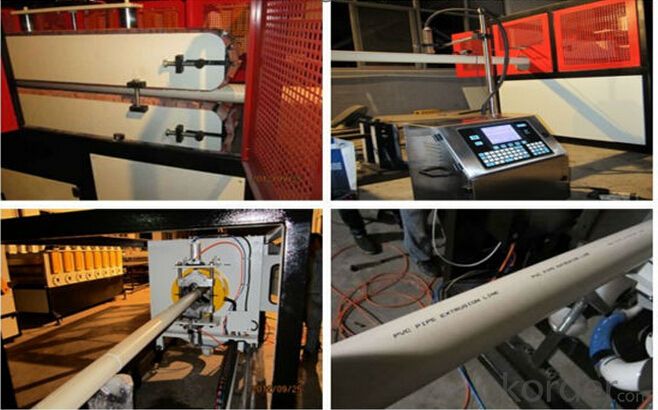

Product show:

FAQ:

1. What are CNBM coming from?

CNBM made the first Chinese screw and barrel in 1978 in brand. Nowaday, in this location BEIJING city, there are more than thousands of companies. After more than 35 years development, CNBM is the TOP 1 extrusion machine supplier in China

2. Why should I choose CNBM?

We follow Germany type of business heading as the worldwide reliable supplier of plastic extrusion line. We have already provided more than 500 lines located in all countries because we are providing the lastest technology, qualified machine, reliable component and best after-service. 300 Engineers are travelling in the world throughout year for installation and test of machine, the after-service are free and availble forever. That's why we grow up from 10 staff company to 3000 staff Pioneer of Chinese extrusion machine supplier.

- Q: What is an extruder?

- This method of forming is continuous molding, such as pipes, plastic profiles, films and so onThe machine also has a single screw, twin-screw, multi screw points.The forming methods are single extrusion and coextrusion only.

- Q: extrusion machine prone to coke material, what is the cause? How to improve or solve?

- Is the place where the material is easy to burn rough? Add stabilizers and lubricants appropriately. Or the outer lubrication part of low molecular weight is replaced by macromolecule lubrication

- Q: What impact does the extruder vacuum pump open or close on the extrusion product?

- If the vacuum pump is opened, the air in the extruded product will be removed and the product material will be more closely packed.

- Q: What are the two types of extrusion?

- Extrusion? The extruder. The extruder is divided into single screw extruder and twin screw extruder, and the twin screw extruder is divided into two parts: flat, double and cone.

- Q: Before and after the original good tune, up and down again before and after the tune, before and after, and up and down again

- The nose is not accurate enough or wornOr the screws are not screwed in placeOr die inappropriate, too large

- Q: Why? What is the raw material of plastics? What is the process flow of the process?.

- 1. injection molding2., the structure is relatively complex, high appearance requirements. Extrusion does not meet requirements3. most are: ABS, ABS+PC, PP and so on4., according to color requirements granulation - drying particles - filling the mold ---- debugging injection molding machine ---- injection molding production - after the selection of finished packaging (if silk screen requirements, but also the need for silk screen)

- Q: What should be paid attention to in the daily maintenance of the extruder?

- HostCheck the patency of cooling water, temperature (general / 26 C), feeding, cylinder temperature and pressure, friction condition of screw and barrel.NoseThe size loss of the perforated plate, the damage and corrosion of the runner surface, and whether the obstruction occurs affect the appearance and output of the product.

- Q: Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- Can, but need feeding machine and related auxiliary mixing granulator, the cost is not low, but the effect is less than double make flat,

- Q: There is a 90 extrusion machine, used in the production of communication cables (outside the cable core is extruded with a layer of LLDPE), now is the configuration of Y2-280M-490KW167A inverter type ACS510197A + ABB), General Motors now found low speed when the current is too large, what reason? How to solve? The details are as follows: used for communication cable production HYA30*2*0.4, 1, line speed is 50 m / min, inverter display frequency 35.3HZ current: 116A; 2, line speed is 40 m / min, inverter display frequency of 28.2hz, current: 140A3, line speed is 35 m / min, the frequency converter significantly method: 157A 24.6HZ frequency current, because the product variety and technical reasons, we need to be in the frequency of 10HZ production. Now, it seems that if I reduce the speed again, the current will probably exceed the rated current. What should I do? Is the motor changed to frequency conversion motor? Or inverter? How to solve? Please heroes pointing, thank you!

- See the ACS510 manual, this type of inverter used in fan pump type, 2605 control methods of determining its U/F, the default value is 2 (the square type, namely fan pump type); for constant torque load, should be set to 1 (linear). When not available, does the debugger not modify the parameter to 1? If that's the case, will the top floor say what happened?

- Q: Wire and cable extrusion machine extrusion die how to quickly adjust the core degree, how can I touch it by hand?,

- It depends on experience, and the lines made by squeezing it are solid. When you make the line, you can see the expansion and skewness of the material!

Send your message to us

CAMX Co-rotating Conical Twin-screw Plastic Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords