Calcium Silicate Bricks Price for High Duty Silica Ceramic Kiln

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 pallet

- Supply Capability:

- 30000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

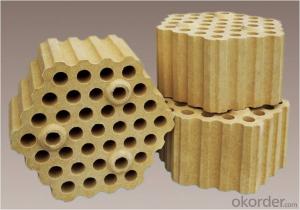

Ceramic firing kiln refractory Silica Brick Description:

Refractory Silica Brick is mainly made of top class silica, via shaping and burning under the high temperature,

Possesses high temperature resistant, high strength and low impurities, etc.

It is mainly used for blast furnaces and hot blast stove.

Features

Ceramic firing kiln refractory Silica Brick Advantage:

1) Silicon oxide is above 95%.

2) Good acid erosion resistance.

3) High softening point

Applications:

Light weight silica bricks are primarily used for furnaces and kilns in metallurgy, steel, power, chemical industry, and electric power and machine building etc areas

Ceramic firing kiln refractory Silica Brick specifications:

Product | AZM-1550 | AZM-1650 | AZM-1680 | |

Index | Index | Index | Index | |

chemical composition | SiC+SiO2 | ≥35 | ≥30 | ≥32 |

Al2O3 | ≥60 | ≥65 | ≥65 | |

Bulk Density(g/cm3) | ≥2.55 | ≥2.65 | ≥2.70 | |

Apparent Porosity (%) | ≤20 | ≤19 | ≤19 | |

Cold Crushing Strength(Mpa) | ≥80 | ≥90 | ≥100 | |

Refractoriness Under Load | ≥1550 | ≥1650 | ≥1680 | |

Thermal Shock Resistance | ≥10 | ≥15 | ≥20 | |

- Q: Physical solid waste disposal

- Reduce crack production and improve yield. The amount of addition is related to the shape and weight of the brick. The bricks can be added to 20% weight less than 25kg; bricks above 25kg can be added to 30%; for the specific type of brick can be added 30%. into waste silica brick should pay attention to this problem

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- The main damage of silicon carbide side wall brick is stress damage, not chemical erosion. Chemical damage is formed prior to the formation of the groove, and the damage to the chemical erosion is little after the formation of the groove.

- Q: Why is the new trend of the high thermal conductivity of silica brick

- The use of high thermal conductivity of silica brick, reducing coke fuel consumption, reduce emissions of pollutants such as NOx, with considerable economic benefits and social benefits, is the future direction of the new technology of using coke oven refractory.

- Q: Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick with silicon oxide content, low melt index, mainly used for glass kiln crown, parapet, wall hanging, small furnace arch superstructure and regenerator.

- Q: The brick is mainly used in the place?

- Open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts.

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly depends on the color and density of brick. Another black clay brick and brick with iron oxide formation and how much the size of bricks

- Q: Why is the three oxidation of two silicon is very harmful impurities in silica brick

- Can generate the material needs is the best way to see the impurity problem!! the first consideration is whether can get the material impurities with what method choice after the time! Miscellaneous reactions cannot have new impurity formation! Selected cannot and need material reaction reagent!

- Q: How to improve the thermal conductivity of the coke silicabrick rate?

- To improve the thermal conductivity of silica brick for coke oven rate method:Manufacture of high density and high thermal conductivity of silica brick, adding additives such as CuO, Cu2O, TiO2, Fe2O3, (FeO), can improve the thermal conductivity of silica brick.

- Q: What are the main constituents of refractory bricks?

- (a) containing refractory brick brick, refers to more than SiO293%, is the main varieties of acid resistant brick. It is mainly used for coke oven building, also used in furnaces all kinds of glass, ceramic and carbon calciner, refractory brick arches and other load-bearing parts, is also used in high temperature bearing part of hot blast stove, but should not be used in thermal equipment below 600 DEG C and the temperature fluctuation in the.

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.

Send your message to us

Calcium Silicate Bricks Price for High Duty Silica Ceramic Kiln

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 pallet

- Supply Capability:

- 30000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords