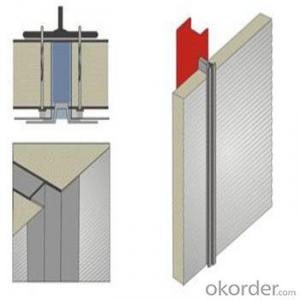

Calcium Silicate Board with EPS Foam Board Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meters m²

- Supply Capability:

- 100000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

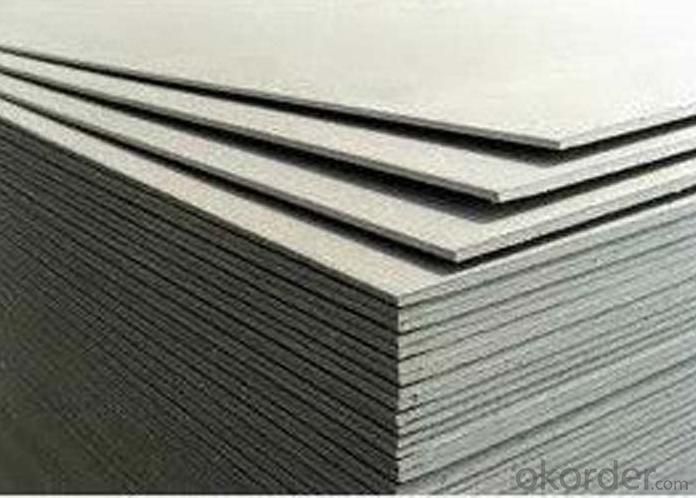

-calcium silicate board

-fiber reinforced cement board

-waterproof

-fireproof

-ideal ceiling and wall partition material

Product technical parameters | |||||||||||||||

| |||||||||||||||

|

- Q: How to cover the building shape to make the building insulation system better

- The connection between the pipe end connection and the steel ring The advantages and disadvantages of the connection: The connection of the pipe end is made by the butt welding method

- Q: Cold storage installation commonly used in insulation materials can be divided into what

- Temporary electricity, scaffolding, foundation pit support, templates, tower crane, material hoist, material Taiwan, lifting, demolition, blasting, winter rain season.

- Q: Will the use of aluminum alloy body notebook which have Please elaborate!

- Overload fever. If you use the 2.5 square, you touch, to determine the high temperature, then change the wire 4 square, anyway than the original wire a large size, if the careless, ignoring this situation, if short-circuit breakdown burning, then the bubble Can help burn Oh

- Q: Roof to do color steel composite board insulation which set which subheading

- With the deepening of reform in recent years, the development of the construction industry is also constantly innovating, the construction of the management model and technical means to a certain extent, has been innovative

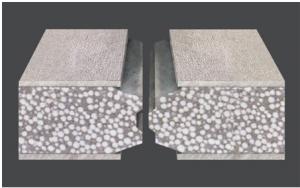

- Q: EPS stupid foam board is composed of what material

- Color steel sandwich panels can not be bent, because the color steel sandwich panels have a certain thickness, bending shear stress will make the core and color steel surface separation, loss of color steel sandwich board carrying capacity, change is very soft. If you need special (curved) Caigang sandwich panels, can be customized to the factory processing, absolutely can not take their own flat bending.

- Q: What is the density of extruded polystyrene board insulation? Insulation

- 1-outer rod; 2-under-pole; 3-horizontal horizontal bar; 4-horizontal horizontal bar; 5-rail; 6-foot plate; 7-angle fastener; 8-rotating fastener; ; 10 - lateral brackets; 11 - main pole; 12 - auxiliary pole; 13 - throwing; 14 - scissors; 15 - pad; 16 - longitudinal sweeping; 17 - lateral sweeping; Type of steel tube household Fu cream Wei Wei puddle pupil pendulum scaffolding position of the bar.

- Q: The outer wall of the pre-sprayed real stone paint, the existing cracks seepage, and now spray rain rainbow good Shi 120 can effectively waterproof it?

- 2) Lap length should not be less than 1m, should be equidistant set 3 rotating fasteners fixed

- Q: House insulation layer in the end is what to do the best

- Commonly used insulation materials: extruded polystyrene foam (extruded board), molded polystyrene foam (ordinary foam board), is sprayed foam polyurethane, foam polyurethane insulation board (products), foam glass, foam Concrete (foam mortar), lightweight aggregate insulation concrete (ceramsite mixed performance class gnawing rescue bugs, etc.), inorganic insulation mortar (glass beads insulation mortar), polystyrene insulation mortar, mineral wool (Rock wool), phenolic resin plate ---------- better expansion of perlite insulation mortar and so on.

- Q: What is the waterproof insulation material on the building?

- 3 When using reinforced concrete piles, the excavation standard is the pile concrete to reach (after design strength) 4 Artificial excavation earth, the two operating distance should be maintained (1 m)

- Q: What can be used after the white foam has been melted?

- Flexible management is a concept of modern economic management category, and rigid management corresponds

1. Manufacturer Overview

| Location | Guangdong,China |

| Year Established | 2009 |

| Annual Output Value | |

| Main Markets | South America20.33% Africa 2.32% Mid East 3.39% Eastern Asia 4.64% Central America 2.14% Northern Europe 5.14% Domestic Market 62.04% |

| Company Certifications | ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Guangzhou,Shenzhen |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcium Silicate Board with EPS Foam Board Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meters m²

- Supply Capability:

- 100000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords