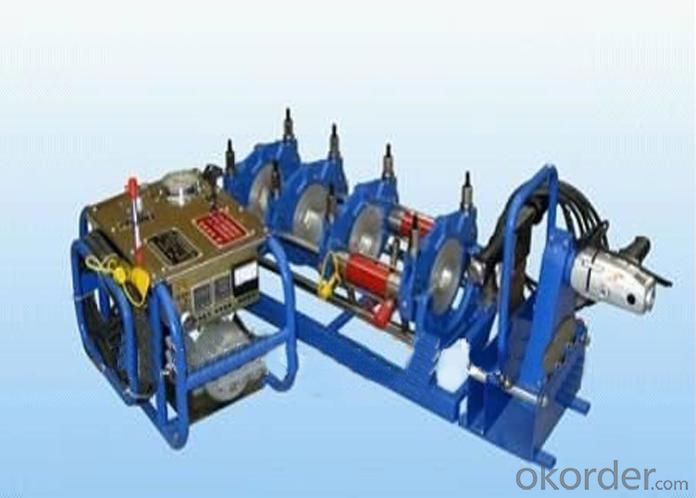

Butt Fusion Machine RDH160

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 Sets set

- Supply Capability:

- 60 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

RDH160 butt fusion machine

1. welding range : from 63mm~ 160mm

2.application: water,gas,irrigation,drainage,construction

RDH160 butt fusion machine

PE Pipe Welding Machine, But Fusion Welding Machine, Hot-melt Welding Machine, Hydraulic butt fusion welding machine. Hydraulic butt welding machine, HDPE butt fusion machine. Welding machine. Butt fusion Equipment

Application:

Suitable for welding of plastic pipes and fittings made of PE,PP,PVDF and can be operated in any complex working condition.

Features:

1. The machine body is equipped with four main clamps with the third clamp axially moved and adjusted.

2. Removable PTFE coated heating plate with separate temperature control system.

3. Electric milling cutter with reversible double cutting edge blades.

4. Hydraulic unit provides welding machine with compressing power.

5. Be made of lightweight and high strength material; simple structure and easy to operate.

6. Low starting pressure ensures reliable welding quality of small pipes.

7. Separate two-channel timer shows time in soaking and cooling phases.

8. High-accurate and shockproof pressure meter indicates clearer readings.

RDH160 butt fusion machine

Welding ranges |

63mm—75mm—90mm-110mm-125mm-140mm-160mm |

Ranges of application |

PE,PP and PVDF |

Working voltage |

~220V ±10%,50Hz |

Environment temperature |

-10° ~ 45° |

Total power |

planing tool: 0.7 kW, heating plate: 1 kW , hydraulic unit motor: 0.75kW |

components |

basic frame, heating plate, planing tool, and support (for planing tool & heating plate) |

heating plate characteristics |

PTFE coated heating plate, adjustable knob for temperature control, difference in heating plate surface temperature ≤±7°. |

Other devices |

Electronic count-down timers for heating and cooling time. |

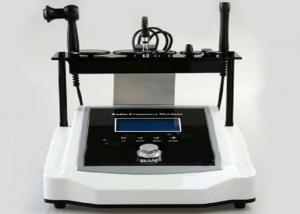

- Q: What does ultrasonic plastic welding machine "15k20k" mean?

- Ultrasonic plastic welding machine 15k20k refers to the transducer working frequency is 15KHz, 20KHz. And the ultrasonic plastic welding machine also has 35KHz, 40KHz. The higher the relative frequency of ultrasonic plastic welding machine, the more expensive the price.15KHz ultrasonic plastic welder power can be divided into 2200W, 2600W, 3000W, 3200W, 4200W five kinds, 20KHz ultrasonic welding machine power 1200W, 1500W, 1800W, 2000W and so on.Ultrasonic plastic welding machine is widely used for traffic equipment industry, automobile industry, electronics industry, communications equipment industry, plastic industry, communication industry, medical industry, household appliances industry, non-woven clothing, stationery and office supplies, packaging and environmental protection industry, food industry, cosmetic industry, toy industry and other daily necessities.Equipment features of LH-2012F ultrasonic plastic welding machine:1 、 adopt the German PINOT original transducer, titanium alloy horn, the output power is large and stable, strong and durable, standard welding mode.2 、 Germany high-quality automatic shock constant balance circuit, automatic frequency tracking function.3, the design of the whole machine is smart, the German linear cross rail device, the chassis platform 4 point level design, very convenient operation.4 、 Japan man-machine interface, PLC control, control time accuracy up to 0.01 seconds. Chinese and English input operation, simple and convenient.5 、 Visual limit adjustment mode, convenient adjustment, high accuracy.6 、 visual fine tuning depth control mode design, cylinder, transducer three in one, direct drive, welding stability.7 、 this machine is specially used for welding precision microelectronic plastic workpieces.8, but also suitable for precision workpiece spot welding, riveting, embossing, dots and other welding processes.

- Q: Ultrasonic plastic welding machine die wave is not strong, how to repair?

- The gray section of the section (whether it looks like a powder after breaking) should be caused by excessive welding and possible causes:1, the welding time is too long, can be appropriate to reduce the delay time or welding time, welding speed or decrease;2, the machine power is too large, you can reduce gear, or choose a smaller power of the machine.If it feels that the wave is not strong, it can be modified as follows: reduce the total height, increase the frequency, and increase the waist height to reduce the frequency. But be careful not to drift out of the best total height.In addition, there may be a strong wave transfer mode is improper, as current mode without impaction, not adjusted to the best state.

- Q: For example: can PP and HDPE be soldered together? What's the strength?

- It depends on the fusion of the two materials,In general, the probability of fusion is small!

- Q: What's the difference between ultrasonic plastic welding machine and ultrasonic plastic hot melt machine?

- HelloBy ultrasonic Xiaobian for you to answer: the principle of ultrasonic plastic welding machine 20KHz is generated by the generator (or 15KHz) high voltage and high frequency signal, through changing systems, converts the signal into high frequency mechanical vibration on plastic workpieces,Through the surface of the workpiece and friction between molecules and the transfer to the interface temperature, when the temperature reaches the melting point of the workpiece itself, the interface is rapidly melting, and then fill in the gaps between the interface, when the motion stops, workpiece cooling under pressure at the same time, then achieve perfect welding.The hot melt machine adopts a pumping plate structure, and the heat of the heating plate is transferred to the welding surface of the upper and lower plastic heating parts by the electric heating method. The surface is melted, and the heating plate is rapidly exited, and the upper and the lower two heating elements are heated, and the fused surface is fused, solidified and integrated.Therefore, ultrasonic plastic welding machine through high-frequency mechanical vibration, friction heat generation plastic welding, and hot melt machine is heated by electric heating plastic softening welding

- Q: Ultrasonic plastic welding machine die is not durable, what material good?

- Titanium alloy will certainly be better. Just expensive.

- Q: Must be able to believe 8700AD ultrasonic plastic welding machine often appear failures and treatment methods?

- BRANSON 8700 imported from the United States, as long as the maintenance of good, nothing

- Q: Why do my ultrasonic plastic welding machines here, some of the mold is always unstable after installation, and some are very stable?

- Causes the ultrasonic machine work to be unstable, the reason has: 1 ultrasonic modulation pattern parameter establishment causes; 2 supersonic wave mold quality question (usually the ultrasonic mold accompanies has the fever phenomenon)

- Q: Please describe in detail the 2015 mould material manufacturing process, pay attention to the problem, the relevant difficult solution

- To do ultrasonic mold of the same product, method of making diversification (material is usually Aluminum Alloy / titanium alloy / steel is also useful; and as the shape but round / square / combination and so on, are different), I can't say this two can let everyone know (because the design of ultrasonic mold needs the knowledge, such as: material mechanics / acoustic / wave, etc.) but must have the ultrasonic testing equipment to ensure the quality of ultrasonic mold.

- Q: Which brand is the best for ultrasonic plastic welding machine?

- Imports are better than domestic, domestic too much, almost the same. Now the ultrasonic plastic welding machine is not stable

- Q: What kind of hot air plastic welding torch and plastic welding machine made in China? Used to weld plastic sheets and tubing

- Used a DSH-D type of hot air welding plastic guns, very good, especially suitable for welding plates, different nozzles can also be welded plastic cloth, seems to be 780 yuan, and spent two years, has not been a problem

1. Manufacturer Overview

| Location | Guangdong, China (Mainland) |

| Year Established | 1993 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | 1-2 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

Butt Fusion Machine RDH160

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 Sets set

- Supply Capability:

- 60 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords