Butt Fusion Machine RDH450

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 10 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

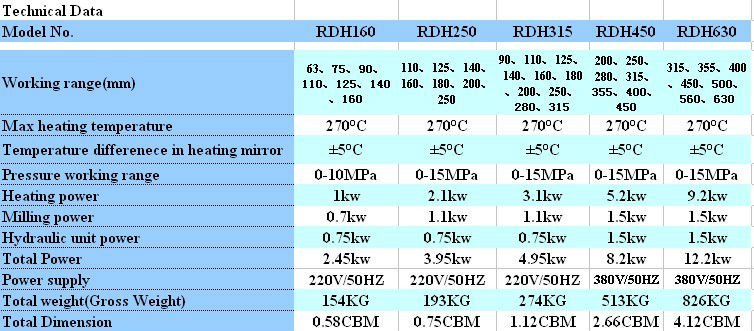

RDH450 butt fusion machine

1. welding range : 280mm~ 450mm

2.application: water,gas,irrigation,drainage,construction

RDH450 Butt Fusion Machine

PE Pipe Welding Machine, But Fusion Welding Machine, Hot-melt Welding Machine, Hydraulic butt fusion welding machine. Hydraulic butt welding machine, HDPE butt fusion machine. Welding machine. Butt fusion Equipment, HDPE Pipe Fitting welding machines. HDPE pipe fittings fusion Equipment

Application:

Suitable for welding of plastic pipes and fittings made of PE,PP,PVDF and can be operated in any complex working condition.

Features:

1. The machine body is equipped with four main clamps with the third clamp axially moved and adjusted.

2. Removable PTFE coated heating plate with separate temperature control system.

3. Electric milling cutter with reversible double cutting edge blades.

4. Hydraulic unit provides welding machine with compressing power.

5. Be made of lightweight and high strength material; simple structure and easy to operate.

6. Low starting pressure ensures reliable welding quality of small pipes.

7. Separate two-channel timer shows time in soaking and cooling phases.

8. High-accurate and shockproof pressure meter indicates clearer readings.

Introduction for RDH450 Butt Fusion Machine:

1), Four main clamps made of light weight alloy.

2), Detaching device is especially designed to break off melted pipes end from the heating plate on the expiry of heating up.

3), Safety switch enables the trimmer to start only when it is located in the operation position.

4), A mechanical lock excludes the disengagement of the trimmer during the operation

5), Removable heating plate with DuPont high quality non-stick PTFE coating, and also equipped with digital temperature controller

6), Low temperature difference in heating plate surface, within 5 degree

7), Incorporated with large easy to read scale pressure gauge, accumulator, pressure regulation valve, swing check valve, high pressure hoses, and quick couplers

8), Imported oil seal & Italian quick couplers

9), Fine operation panel with clearly strong meshing printing characters.

- Q: What should be paid attention to when welding the air conditioner copper pipe welding machine?

- The copper wire of the air conditioner is not long enough to be welded and connected. Will not affect the effect. The method is: after the direct cutting off, the connection head is connected, after connecting, welding, welding is good.

- Q: What is the welding machine for glass fibre reinforced plastic cable protection tube?

- Glass fiber reinforced plastic cable tube is mainly adhesive and socket connection, it can not be welded.

- Q: How to weld the air conditioner copper tube welding?

- Air conditioning copper pipe welding choose high-frequency welding, don't bother, which do not have welding, acetylene welding and environmental wind! Selection of high frequency welding choose Wei Edison, good quality, good effect!

- Q: Which brand is the best for plastic pipe welding machine? How to ensure the quality of PE pipe welding machine?

- Plastic welding is of course with the Swiss LEISTER brand well, can use the mirror to PE pipe welding butt welding

1. Manufacturer Overview

| Location | Hebei,China (Mainland) |

| Year Established | 2009 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe South Asia |

| Company Certifications | RoHS;CE certificate;CE certificate;Corporate Business license |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | tianjian port,shanghai port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Butt Fusion Machine RDH450

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 10 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords