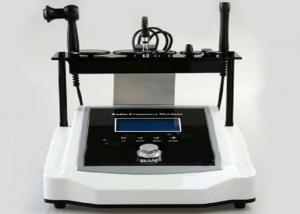

Ultrasonic Plastic Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 80 Pieces per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

plastic welding machine

1.welding round plastic product

2.perfect effect, air-tight and water-tight

3.custom making is ok

quality plastic welding machine, weld round plastic items

1.for welding round plastic product

2.easy maintenance

3.perfect effect, air-tight and water-tight

4.custom making is welcome

5.made of quality stainless steel

Applications:

to weld any round plastic, globe plastic item, such as kettle, ball, float ball, bucket, cup, thermos shell etc

- Q: What's the difference between metal welding machine and plastic welding machine?

- From the point of view of laser welding:For general thin plate metal welding, a solid pulsed laser or a medium power fiber laser is adopted; a thicker metal plate is welded; a high power Co2 laser or a high power light laser is used.Plastic welding has CO2 laser welding, semiconductor 808nm975nm welding, fiber laser also used in plastic welding.

- Q: What are the causes of the high power transistors in ultrasonic plastic welding machines?

- The driving signal drives the high power triode (IGBT) to work at high frequency (hard switching), which is susceptible to interference (mainly high-frequency)

- Q: What are their differences? What are the manufacturers of high frequency welding machines?

- To tell you the truth, products from different processes use different equipment. The main idea is what the product is and what kind of equipment is plastic decided to use?!

- Q: What's wrong with high ultrasonic plastic welding machines that have been overloaded?

- 1, no-load test, such as the normal operating current, may be exposed to welding welding head and welding parameters of objects or between the seat should not touch the regulation failure.2 、 no-load test is not normal(1) to observe whether there are cracks in welding, installation is firm(2) remove the ultrasonic welding machine welding head of no-load test, whether the exclusion is the transducer horn + problems, step by step out. The possibility of falling horn failure + transducer, the new head replacement to judge.3, sometimes no-load tests are normal, and can not work normally, there may be an internal welding energy original change, lead to poor transmission of energy, there is a relatively simple method to judge: hand touch method.The welding head or horn surface normal work when the amplitude is very uniform, hand is silky smooth, when the sound transmission is not smooth, it will have a bubble or burr feeling touch, then we must use exclusion to exclude parts of the problem. The generator is not normal, can also have the same situation, because normally detection transducer input waveform should be as smooth as a sine wave, sine wave can produce this kind of phenomenon is also the peak or abnormal waveform, then can be replaced with discrimination in a sound training element.

- Q: What kind of factory will use big ultrasonic plastic welding machine?

- Application industry:Plastic welding machine is widely used in the automotive industry, electronics industry, medical industry, household electrical appliance industry, non-woven clothing, office supplies, packaging industry, toy industry, etc..The automotive industry: plastic body parts, car doors, car auto meter, auto lamp, sun visor, interiors, filter, reflective material, reflective spike, bumper, cable, motorcycle plastic filter, radiator, brake fluid tank, oil tank, oil tank, air duct, exhaust purifier, filter plate, tray;Plastic electronics: prepaid water meter, communication equipment, cordless telephone, mobile phone accessories, mobile phone shell, shell, battery charger, valve controlled sealed lead-acid battery maintenance, 3 inch floppy disk, U disk, SD card, CF card, USB connectors, bluetooth;Toys stationery: folders, photo albums, folding box, PP hollow board, pen, ink cartridges, toner cartridges;Medical Daily: watches, kitchenware, oral liquid bottle, bottle cap, mobile phone accessories, some gold soft brush, daily necessities;Health products: Children's products, air mattress, racks, knife, gardening supplies, kitchenware sanitary ware, shower, gold soft brush, shower head, bottle, cosmetic bottle, coffee pot, washing machine, air dehumidifier, electric irons, electric kettle, vacuum cleaner, metal box cover and geogrid etc..

- Q: What's the difference between ultrasonic plastic welding machine and ultrasonic plastic hot melt machine?

- It's all one thing

- Q: Ultrasonic plastic welding machine die is not durable, what material good?

- Titanium alloy will certainly be better. Just expensive.

- Q: Why do my ultrasonic plastic welding machines here, some of the mold is always unstable after installation, and some are very stable?

- Ultrasonic power is not enough, but also some of the material problems caused by the product

- Q: Which brand is the best for ultrasonic plastic welding machine?

- South Nekon Machinery Co., Ltd. is a large-scale ultrasonic equipment research and development, production and marketing enterprises, the company was founded in 1997, the division is specialized in producing all kinds of plastic welding standard 2600W-3200W plastic welding machine, plastic welding machine, plastic welding machine 4200W-5200W high-power welding equipment; 15K, 20K, 28K, 40K and other precision welding equipment, and all kinds of non-standard plastic welding equipment, plastic welding machine, plastic welding machine, four head six head plastic machine, hollow board glue box special welding machine, welding machine, guardrail tube, rotary hot plate welding machine, welding machine, automotive dashboard welding, automobile sunshade plate welding machine, welding machine, automobile lamp automobile bumper welding machine, and designed specifically for customers all kinds of non-standard automatic plastic welding equipment.

- Q: What kind of hot air plastic welding torch and plastic welding machine made in China? Used to weld plastic sheets and tubing

- The quality is imported, the price is expensive, the domestic good should be Wenzhou LANSITE welding equipment factory production of Lansite brand welding gun, plastic welding machines. You can go to Taobao to find out. The heater in their house is good

1. Manufacturer Overview

| Location | Guangdong, China (Mainland) |

| Year Established | 1993 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | 1-2 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

Ultrasonic Plastic Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 80 Pieces per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords