Automatic Ultrasonic Plastic Welder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

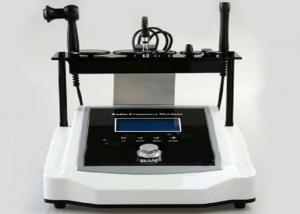

automatic plastic welder

1.high quality material

2.fast welding on plastic item

3.Custom-made is available

4.Warranty

Automatic Ultrasonic Plastic Welder

our factory designs and make custom-purpose welding machines

Features:

1.high quality air-drive mechanism & components

2.ceramic coated converter, ensure constant and powerful output

3.titanium alloy booster

4.fast welding on plastic item

5.Custom-made is available

6.Easy Maintenance

CUSTOM MAKING IS WELCOME

Model |

HN-400 |

HN-800 |

HN-1200 |

HN-1500 |

HN-2000 |

Ultrasonic Power |

400W |

800W |

1200W |

1500W |

2000W |

Ultrasonic Frequency |

28/40 Khz |

28/40 Khz |

15/20 Khz |

15/20Khz |

15/20Khz |

Pneumatic Cylinder |

75 mm |

75 mm |

75mm |

75mm |

75mm |

Ultrasonic Time |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

Stay Time |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

Lingerin Time |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

Power supply | AC110-120V, AC220-240V | AC110-120V, AC220-240V | AC110-120V, AC220-240V | AC110-120V, AC220-240V | AC110-120V, AC220-240V |

- Q: What's the difference between metal welding machine and plastic welding machine?

- Just look at the name. Ah, a welding plastic, a metal welding

- Q: What does ultrasonic plastic welding machine "15k20k" mean?

- Refers to the frequency of the transducer is 20KHz or 15KHz?

- Q: What are the causes of the high power transistors in ultrasonic plastic welding machines?

- The driving signal drives the high power triode (IGBT) to work at high frequency (hard switching), which is susceptible to interference (mainly high-frequency)

- Q: For example: can PP and HDPE be soldered together? What's the strength?

- The same kind of material is easy to solder, PP melting point is higher, not easy to weld, try a good point

- Q: How many kinds of ultrasonic welding machine power are there?

- Single machine can do 200W - 5600W ultrasonic welding machine.

- Q: What's the difference between ultrasonic plastic welding machine and ultrasonic plastic hot melt machine?

- Ultrasonic welding machine is to use high-frequency vibration to produce high temperature plastic welding. Hot plate welding is done by heating the tube directly against the heating of the plastic.

- Q: Ultrasonic plastic welding machine die is not durable, what material good?

- Titanium alloy will certainly be better. Just expensive.

- Q: Why do my ultrasonic plastic welding machines here, some of the mold is always unstable after installation, and some are very stable?

- Ultrasonic power is not enough, but also some of the material problems caused by the product

- Q: Ultrasonic plastic welding machine power, the better the better?

- Of course not, the greater the power the better, but according to the size of the plastic products to determine the size of the welding surface, the need for power

- Q: What kind of hot air plastic welding torch and plastic welding machine made in China? Used to weld plastic sheets and tubing

- Used a DSH-D type of hot air welding plastic guns, very good, especially suitable for welding plates, different nozzles can also be welded plastic cloth, seems to be 780 yuan, and spent two years, has not been a problem

1. Manufacturer Overview

| Location | Guangdong, China (Mainland) |

| Year Established | 1993 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | 1-2 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

Automatic Ultrasonic Plastic Welder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords