Building Lifter SCD250/250 Chinese Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of SCD250/250 Building Lifter Description

To serve the increasing demand for highrise construction, we developed the high speed VF hoist, with a max.lifting speed of 96 m/min.

It has the following structure:

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/F control: the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoids slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the energy consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack,pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection, low voltage protection, overcurrent, overload and anti-stalling protection functions.

7. The System applies the special software for hoists developed by our company, making the operation more safe and reliable.

Main Features of SCD250/250 Building Lifter

1. The recomended cage dimension(L*W*H)(m): 2.0*1.0*2.5, 2.5*1.0*2.5, 2.5*1.3*2.5, 3.0*1.5*2,5, 3.2*1.5*2.5, 3.8*1.5*2.5, 4.0*1.5*2.5, 4.2*1.5*2.5 etc. We can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to yout requirements.

3. The mast section and the tie-in surface can adopt paint-spray, or hot galvanizing processing.

4. Both domestic and imported driving systems are available.

SCD250/250 Building Lifter Specification

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage building hoist can be changed into single cage type,

| Type | Payload(kg) | Lifting Speed (m/min) | Motor Power(kw) | Safety Device | ||

| Twin Cage Hoist | No Counterweight | SC100/100 | 2*1000 | 0~60 | 2*3*11 | 2*SAJ30-1.4 |

| SC120/120 | 2*1200 | 0~60 | 2*3*11 | 2*SAJ30-1.4 | ||

| SC160/160 | 2*1600 | 0~60 | 2*3*15 | 2*SAJ30-1.4 | ||

| SC200/200 | 2*2000 | 0~60 | 2*3*15 | 2*SAJ40-1.4 | ||

| SC250/250 | 2*2500 | 0~60 | 2*3*18.5 | 2*SAJ50-1.4 | ||

| SC270/270 | 2*2700 | 0~60 | 2*3*18.5 | 2*SAJ50-1.4 | ||

| SC300/300 | 2*3000 | 0~60 | 2*3*22 | 2*SAJ50-1.4 | ||

| SC320/320 | 2*3200 | 0~60 | 2*3*22 | 2*SAJ50-1.4 | ||

| With Counterweight | SCD200/200 | 2*2000 | 0~60 | 2*2*15 | 2*SAJ40-1.4 | |

| SCD250/250 | 2*2500 | 0~60 | 2*2*18.5 | 2*SAJ50-1.4 | ||

| SCD270/270 | 2*2700 | 0~60 | 2*2*18.5 | 2*SAJ50-1.4 | ||

| SCD300/300 | 2*3000 | 0~60 | 2*3*15 | 2*SAJ50-1.4 | ||

| SCD320/320 | 2*3200 | 0~60 | 2*3*15 | 2*SAJ50-1.2 |

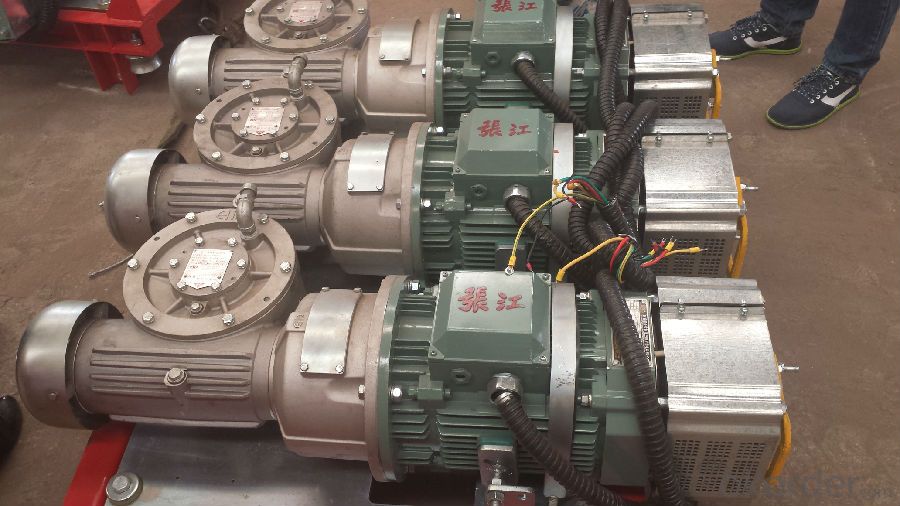

Images of SCD250/250 Building Lifter

FAQ of SCD250/250 Building Lifter

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks for a description of the process of using an electric motor in the context of a building hoist, which is a device used for lifting and lowering materials in construction.

- <p>To use an electric motor with a building hoist, first ensure the hoist is properly installed and secured. Connect the hoist to a power source and check that all safety features are operational. Turn on the motor and test the hoist's movement in both directions to confirm functionality. When lifting materials, ensure they are evenly distributed and securely attached to the hoist. Operate the motor to lift or lower the load, maintaining a steady speed and monitoring for any signs of strain or malfunction. Always follow the manufacturer's guidelines and safety precautions to prevent accidents.</p>

- Q: Explain the distinctions between electric and hydraulic power sources used in building hoists.

- <p>Electric hoists use electric motors to generate power, which is more environmentally friendly and requires less maintenance. They are often quieter, easier to control, and can be more energy-efficient. Hydraulic hoists, on the other hand, rely on fluid pressure to generate power. They can provide greater lifting capacity and are often used in heavy-duty applications. Hydraulic systems can be more complex to maintain and repair, and they may not be as energy-efficient as electric hoists. However, they offer smooth and controlled lifting, which is beneficial in certain construction scenarios.</p>

- Q: This question asks for methods to reduce the time a lifting device, such as a building hoist, is not operational and the expenses associated with its upkeep.

- <p>Minimizing downtime and maintenance costs for lifting equipment, including building hoists, involves a combination of proactive measures and regular maintenance. Implement a preventive maintenance schedule to address potential issues before they cause significant downtime. Use high-quality components to reduce the frequency of repairs. Train operators to handle equipment correctly and perform basic troubleshooting. Regularly inspect and lubricate moving parts to prevent wear and tear. Implement a condition monitoring system to detect early signs of malfunction. Finally, keep spare parts readily available to expedite repairs and minimize downtime.</p>

- Q: What are the primary materials and components typically utilized in the construction of building hoists?

- <p>Building hoists, also known as construction hoists, are typically made from a combination of steel, aluminum, and sometimes plastic. The frame and main structure are usually constructed from steel for strength and durability. Aluminum is often used for components like the platform and railing due to its lightweight properties, which can reduce the overall weight of the hoist. Plastic components may be used for certain parts to enhance resistance to weather and corrosion. Additionally, hoists may incorporate electrical and mechanical systems, which include cables, gears, and motors, to facilitate the hoisting and lowering of materials and personnel.</p>

- Q: This question asks for the steps or methods to fix a building hoist that is not working properly.

- <p>To repair a malfunctioning building hoist, first, ensure the hoist is powered off and disconnected from any power source to ensure safety. Inspect the hoist for visible damage or loose parts. Check the motor, cables, and control panel for any signs of wear or damage. If the issue is mechanical, such as a stuck cable or a jammed pulley, disassemble the affected parts and clean or replace them as necessary. For electrical issues, inspect the wiring and connections for any shorts or breaks. Consult the hoist's manual for troubleshooting guides specific to the model. If the problem persists or if you're unsure about any steps, it's best to contact a professional technician for repair to avoid further damage or safety hazards.</p>

- Q: Is it safe to use an electric lifting device indoors if it is not certified for indoor use?

- <p>It is not advisable to use an electric lifting device indoors if it is not certified for such use. Non-certified devices may not meet safety standards for indoor environments, including electrical safety, structural integrity, and risk of fire. Using uncertified equipment can lead to accidents, injuries, or property damage. Always ensure that any lifting equipment complies with local regulations and is suitable for the intended environment to maintain safety.</p>

- Q: What specific regulations or conditions must be met when utilizing lifting equipment in construction or factory environments?

- <p>Yes, there are special requirements for using lifting equipment in construction sites and factories. These include adherence to safety regulations, regular maintenance and inspection, proper operator training, and ensuring the equipment is suitable for the task. Compliance with local and national laws such as OSHA in the U.S. or CE marking in the EU is crucial. Equipment must be certified safe for use, and operators must be licensed and follow safety protocols. Additionally, load capacities must be respected, and lifting operations must be planned and supervised to prevent accidents.</p>

- Q: The construction elevator should have those procedures

- The construction elevator is short for construction. It is an important equipment in high-rise building construction, and construction site accident hazards easily, because it can cause many major accidents, injuries in the inspection should be listed as a key to check the content.

- Q: This question asks for the method to change the angle at which a building hoist operates.

- <p>Adjusting the angle of a building hoist involves several steps. First, ensure the hoist is turned off and disconnected from power sources. Next, locate the hoist's tilt adjustment mechanism, which is typically found at the base or on the mast. This mechanism often consists of a set of bolts or pins that can be loosened to allow the angle to be changed. Adjust the angle by moving the mast or base to the desired position, ensuring it is level and stable. Once the correct angle is achieved, tighten the bolts or pins to secure the hoist in place. Always follow the manufacturer's guidelines and safety precautions when making adjustments to prevent accidents.</p>

- Q: Is it possible to use two lifting devices simultaneously to lift an object that is heavier than the maximum weight each device can handle individually?

- <p>Yes, two lifting devices can be used together to lift a heavier object than either one can handle alone, provided that both devices are capable of supporting the combined weight and are properly synchronized. This requires careful planning and coordination to ensure the safety of the operation and the integrity of the lifting devices. The total weight capacity of the combined system should be greater than the weight of the object being lifted, and the devices must be designed to work in tandem without overloading or causing damage.</p>

Send your message to us

Building Lifter SCD250/250 Chinese Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords