Building Lifter SCD320/320 Hoist Crane in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of SCD320/320 Building Lifter Description

To serve the increasing demand for highrise construction, we developed the high speed VF hoist, with a max.lifting speed of 96 m/min.

It has the following structure:

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/F control: the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoids slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the energy consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack,pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection, low voltage protection, overcurrent, overload and anti-stalling protection functions.

Main Features of SCD320/320 Building Lifter

1. The recomended cage dimension(L*W*H)(m): 2.0*1.0*2.5, 2.5*1.0*2.5, 2.5*1.3*2.5, 3.0*1.5*2,5, 3.2*1.5*2.5, 3.8*1.5*2.5, 4.0*1.5*2.5, 4.2*1.5*2.5 etc. We can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to yout requirements.

3. The mast section and the tie-in surface can adopt paint-spray, or hot galvanizing processing.

4. Both domestic and imported driving systems are available.

SCD320/320 Building Lifter Specification

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage building hoist can be changed into single cage type,

| Type | Payload(kg) | Lifting Speed (m/min) | Motor Power(kw) | Safety Device | ||

| Twin Cage Hoist | No Counterweight | SC100/100 | 2*1000 | 0~60 | 2*3*11 | 2*SAJ30-1.4 |

| SC120/120 | 2*1200 | 0~60 | 2*3*11 | 2*SAJ30-1.4 | ||

| SC160/160 | 2*1600 | 0~60 | 2*3*15 | 2*SAJ30-1.4 | ||

| SC200/200 | 2*2000 | 0~60 | 2*3*15 | 2*SAJ40-1.4 | ||

| SC250/250 | 2*2500 | 0~60 | 2*3*18.5 | 2*SAJ50-1.4 | ||

| SC270/270 | 2*2700 | 0~60 | 2*3*18.5 | 2*SAJ50-1.4 | ||

| SC300/300 | 2*3000 | 0~60 | 2*3*22 | 2*SAJ50-1.4 | ||

| SC320/320 | 2*3200 | 0~60 | 2*3*22 | 2*SAJ50-1.4 | ||

| With Counterweight | SCD200/200 | 2*2000 | 0~60 | 2*2*15 | 2*SAJ40-1.4 | |

| SCD250/250 | 2*2500 | 0~60 | 2*2*18.5 | 2*SAJ50-1.4 | ||

| SCD270/270 | 2*2700 | 0~60 | 2*2*18.5 | 2*SAJ50-1.4 | ||

| SCD300/300 | 2*3000 | 0~60 | 2*3*15 | 2*SAJ50-1.4 | ||

| SCD320/320 | 2*3200 | 0~60 | 2*3*15 | 2*SAJ50-1.2 |

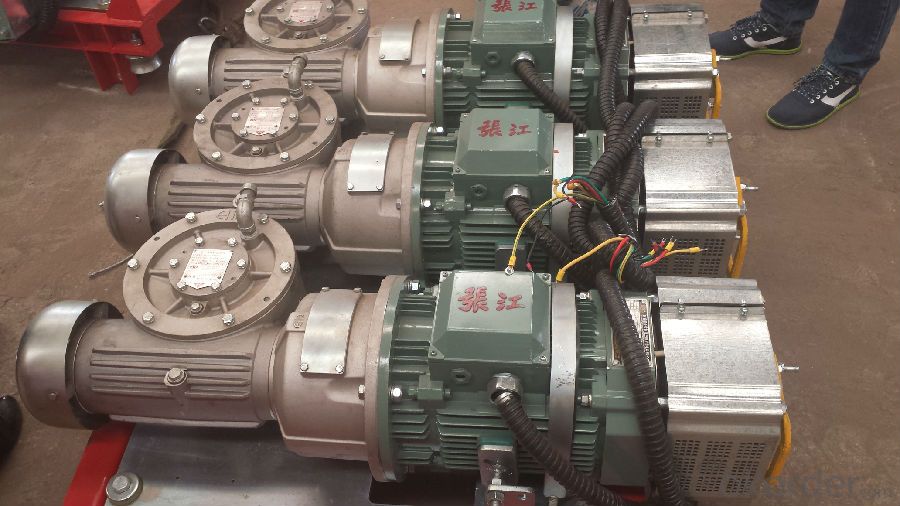

Images of SCD320/320 Building Lifter

FAQ of SCD320/320 Building Lifter

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: What are the primary parts that make up a building hoist system?

- <p>The main components of a building hoist include the hoist machine, which is the driving mechanism; the hoist shaft, a vertical structure that houses the hoist; the lifting platform or cage, which carries materials and personnel; the mast or tower, providing support and stability; the counterweight, which balances the load; safety devices such as limit switches and brakes; the control system for operation; and the electrical system that powers the hoist. Additionally, there are guide rails, cables, and buffers that ensure smooth and safe operation.</p>

- Q: What's going on with the decline in construction lift

- Check to see if there is any problem with holding the brake. There is no problem with the contactless contactor, which is the most common cause of the vehicle. Normal contactor will rebound at the moment of you to stop operation, adhesion would be stuck there for a few seconds and then bounce back, in a few seconds the brake coil is charged, the brake is still in open state, but the motor has stopped working, so will decline, it's adhesion change the same contactor change.

- Q: This question asks about the process of installing a new building hoist, which is a piece of equipment used in construction to lift materials and personnel.

- <p>Installing a new building hoist involves several steps: 1) Site preparation, ensuring the area is clear and level. 2) Unpacking and inspecting the hoist components for any damage. 3) Assembling the hoist tower, starting with the base and working upwards. 4) Installing the drive unit and cable system. 5) Attaching the counterweight and safety devices. 6) Rigging the hoist to the building structure for stability. 7) Conducting a thorough inspection and testing the hoist for safety and functionality. 8) Obtaining any necessary permits and approvals. 9) Training operators on the safe use of the hoist. It's crucial to follow the manufacturer's instructions and local regulations when installing a building hoist.</p>

- Q: This question asks for methods to reduce the time a lifting device, such as a building hoist, is not operational and the expenses associated with its upkeep.

- <p>Minimizing downtime and maintenance costs for lifting equipment, including building hoists, involves a combination of proactive measures and regular maintenance. Implement a preventive maintenance schedule to address potential issues before they cause significant downtime. Use high-quality components to reduce the frequency of repairs. Train operators to handle equipment correctly and perform basic troubleshooting. Regularly inspect and lubricate moving parts to prevent wear and tear. Implement a condition monitoring system to detect early signs of malfunction. Finally, keep spare parts readily available to expedite repairs and minimize downtime.</p>

- Q: This question asks for the method to determine the maximum weight an object can safely be lifted by a lifting device.

- <p>To calculate the weight of an object that can be safely lifted by a lifting device, you must consider several factors. First, determine the lifting capacity of the device, which is the maximum weight it is designed to handle. This information is typically provided by the manufacturer. Next, account for the weight of any additional equipment, such as slings or cables, that will be used in the lift. Subtract this from the lifting capacity to find the maximum weight the object can be. Ensure all safety margins and regulations are observed, as these can affect the safe weight limit. Always err on the side of caution to prevent overloading the lifting device.</p>

- Q: This question asks about the procedures and methods for maintaining and repairing a building hoist, which is a type of lifting equipment used in construction.

- <p>To maintain and repair a building hoist, follow these steps: Regularly inspect the hoist for any signs of wear and tear or malfunction. Lubricate moving parts as per the manufacturer's recommendations to reduce friction and prevent rust. Check and replace worn cables, pulleys, and other components. Ensure that safety devices like limit switches and emergency stops are functioning correctly. For repairs, address any mechanical failures, replace broken parts, and make sure the electrical system is in good condition. Always follow the manufacturer's guidelines and consult with a professional if the issue is complex or beyond your expertise. Regular maintenance and prompt repairs can extend the life of the hoist and ensure safe operation.</p>

- Q: What are the necessary maintenance tasks and considerations for ensuring the safe and efficient operation of a building hoist?

- <p>The maintenance requirements for a building hoist include regular inspections, lubrication, and checks on all mechanical components. It is crucial to inspect the hoist's cables, pulleys, and brackets for wear and tear. The drive mechanism and safety devices should be tested for proper functioning. Lubrication of moving parts is essential to reduce friction and prevent overheating. Additionally, the electrical system should be checked for any faults or damage. It's important to keep the hoist clean and free of debris to prevent any operational issues. Following the manufacturer's guidelines for maintenance intervals and procedures is vital to ensure the hoist remains safe and efficient.</p>

- Q: Is it possible to use two lifting devices simultaneously to lift an object that is heavier than the maximum weight each device can handle individually?

- <p>Yes, two lifting devices can be used together to lift a heavier object than either one can handle alone, provided that both devices are capable of supporting the combined weight and are properly synchronized. This requires careful planning and coordination to ensure the safety of the operation and the integrity of the lifting devices. The total weight capacity of the combined system should be greater than the weight of the object being lifted, and the devices must be designed to work in tandem without overloading or causing damage.</p>

- Q: Is it feasible to utilize a building hoist for lifting heavy objects when the ground is not level?

- <p>A building hoist is generally designed for vertical lifting in a stable and level environment. Using it on uneven ground can be hazardous and is not recommended due to the risk of tipping or instability. For lifting heavy objects on uneven ground, it's advisable to use specialized equipment like mobile cranes or all-terrain forklifts that are designed to handle such conditions. Always consult the manufacturer's guidelines and safety regulations before using any lifting equipment.</p>

- Q: Is it possible to utilize a building hoist for elevating construction materials at construction sites?

- <p>Yes, building hoists are commonly used for lifting materials at construction sites. They are designed to transport heavy construction materials and personnel vertically, which is essential for multi-story construction projects. These hoists are equipped with safety features and are operated by trained personnel to ensure the secure and efficient movement of materials and workers.</p>

Send your message to us

Building Lifter SCD320/320 Hoist Crane in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords