Building Hoist SC200/200B Construction Hoist high Quality

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Construction Hoist Description

The construction hoist product produced by Fangyuan has achieved internationally advanced level in terms of industrial design, control and the drive performance, as well as the operation safety and comfortableness.

And Fangyuan is also making efforts to keep improving the product, as what the construction hoist lifts is not only people and material, but also a kind of social responsibility and service concept…

The new generation SC series of construction hoists adopt modular structure, ergonomic design and advanced manufacturing technology, thus the adaptability and reliability of the product is greatly improved, e.g. the max. lifting height can reach 300 meters.

The product adopts multiple patented technologies, reaches advanced level in China, and the market share in domestic market is increasing year by year.

The product has also been exported to overseas countries like Russia, Turkmenstan, Vietnam, etc. winning the confidence of customers of both home and abroad

Main features of Construction Hoist

1. The cage drive system is equipped with buffering device, so the cage moves more stable.

2. The ergonomically designed cage interior improves comfortableness.

3. The unique structural design has applied for patent.

4. The typical technologies ensure the malposition difference of the guide rail.

5. The excellent parts in the industry ensures reliable quality of the machine.

6. Precise assembly and accurate drive.

7. Professional solutions for special projects.

8. The complete safety devices ensures reliable control system.

Construction Hoist Specifiction

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage construction elevator can be changed into single cage type, such as SCD200.

Model | SC200/200 | SC200/200BP | SCD200/200 | SC200/200B | ||

Configuration | Standard type | Frequency conversion | Counterweight type | Export type | ||

Rated load | kg | 2000/2000 | 2000/2000 | 2000/2000 | 2000/2000 | |

Cage size L×W×H | m | 3×1.3×2.2 | 3×1.3×2.2 | 3×1.3×2.2 | 3×1.3×2.2 | |

Passengers | 16/16 | 16/16 | 16/16 | 16/16 | ||

Max.lifting height | m | 150 | 300 | 150 | 150 | |

Max.height of free end | m | 9 | 9 | 9 | 9 | |

Lifting speed | m/min | 33 | 0~60 | 33 | 33 | |

Capacity of small hoist | kg | 200 | 200 | 200 | 200 | |

Std.section L×W×H | mm | 650×650×1508 | ||||

Electric motor | Type | Disc brake electic motor | ||||

Power | kW | 11×3/11×3 | 11×3/11×3 | 11×2/11×2 | 11×3/11×3 | |

Speed limiter | Action speed | m/s | 1.2 | 1.45 | 1.2 | 1.2 |

Rated brake load | kN | 40 | 40 | 30 | 40 | |

Model | SCD200/200B | SC100/100 | SCD200 | ||

Configuration | Counterweight type | No counterweight | Counterweight type | ||

Rated load | kg | 2000/2000 | 1000/1000 | 2000 | |

Cage size L×W×H | m | 3×1.3×2.2 | 3×1.3×2.2 | 3×1.3×2.2 | |

Passengers | 16/16 | 12/12 | 16 | ||

Max.lifting height | m | 150 | 150 | 150 | |

Max.height of free end | m | 9 | 9 | 9 | |

Lifting speed | m/min | 33 | 33 | 33 | |

Capacity of small hoist | kg | 200 | 200 | 200 | |

Std.section L×W×H | mm | 650×650×1508 | |||

Electric motor | Type | Disc brake electic motor | |||

Power | kW | 11×2/11×2 | 11×2/11×2 | 11×2 | |

Speed limiter | Action speed | m/s | 1.2 | 1.2 | 1.2 |

Rated brake load | kN | 30 | 30 | 30 | |

The above parameters are subject to change without prior notice, please refer to the actual product.

Note: Both cage size of 3×1.3×2.2 and 3.2×1.5×2.4 are available for of each model (Excl. export type).

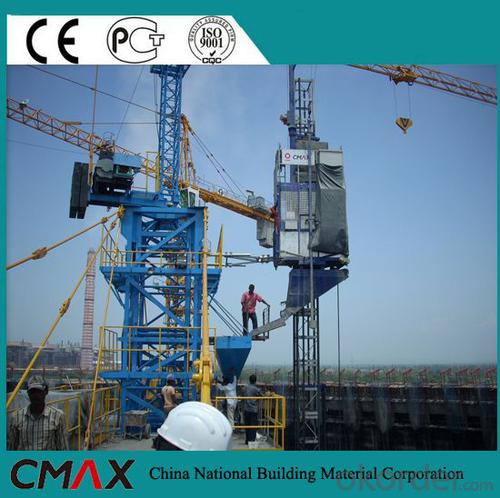

Images of construction hoist

FAQ of Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

- Q: Is it possible to use a single automatic building hoist to lift multiple objects simultaneously?

- <p>Yes, an automatic building hoist can be used to lift multiple objects at once, provided that the combined weight of the objects does not exceed the hoist's maximum load capacity. It is crucial to ensure that the hoist is designed for such operations and that all safety precautions are taken to prevent overloading, which can lead to accidents. The hoist should be equipped with a load limiter to automatically cut off power if the load exceeds safe limits, ensuring the safety of the operation.</p>

- Q: This question asks for a guide on how to change the tightness of the ropes on a construction hoist.

- <p>Adjusting the tension on a building hoist involves several steps. First, ensure the hoist is powered off and secured to prevent any movement. Locate the rope tensioning mechanism, often found at the base or top of the hoist. This could be a ratchet system, a spring-loaded mechanism, or a manual adjustment bolt. For ratchet systems, adjust the tension by turning the ratchet handle to tighten or loosen the rope. For spring-loaded mechanisms, adjust the spring tension by turning the adjustment bolt. Ensure the rope is properly seated in the pulley system and not frayed or damaged. After adjusting, test the hoist with a small load to ensure the tension is appropriate and the hoist operates smoothly. Always refer to the manufacturer's manual for specific instructions and safety precautions.</p>

- Q: This question seeks to understand the various types of electric lifting equipment utilized in the construction industry.

- <p>In the construction industry, various types of electric lifting equipment are used to facilitate the movement of heavy materials and equipment. Some of the common types include: 1. Electric Hoists: These are used for vertical lifting and lowering of loads. 2. Electric Cranes: They are mobile lifting machines with a long boom and can move loads horizontally and vertically. 3. Electric Forklifts: They are used for lifting and transporting heavy loads in a warehouse or construction site. 4. Electric Scissor Lifts: These are mobile platforms that can be raised to allow workers to reach high areas. 5. Electric Stackers: Used for stacking and unstacking materials in a warehouse. 6. Electric Pallet Trucks: These are used for moving heavy pallets of materials. Each type of equipment serves a specific purpose and is chosen based on the requirements of the construction project.</p>

- Q: Is it permissible to use a building hoist for the purpose of lifting hazardous materials?

- <p>A building hoist is typically not designed for lifting dangerous materials. It is meant for the transportation of construction materials and personnel within a building. Lifting hazardous materials requires specialized equipment and procedures to ensure safety. Always refer to the manufacturer's guidelines and local regulations for the appropriate use of hoisting equipment and handling of dangerous materials.</p>

- Q: This question asks for the safety precautions that should be taken when operating electric-hydraulic construction hoists.

- <p>Safety measures for using electric-hydraulic building hoists include regular maintenance and inspection to ensure all components are in good working order. Operators must be trained and certified, following all safety protocols. Never exceed the hoist's load capacity. Ensure that safety hooks and chains are in place and secure. Keep the hoist area clear of debris and unauthorized personnel. Use proper lifting techniques and avoid sudden starts or stops. Always inspect the load before lifting to ensure it is stable and secure. Emergency stop switches should be easily accessible. Ensure that all safety guards are in place and functioning properly. Adhere to all local regulations and manufacturer's guidelines.</p>

- Q: How many people are there for construction workers

- At the end of the 20th century, the elevator was powered by the permanent magnet synchronous towing machine. It greatly reduces the space of the machine room, and it has the advantages of low energy consumption, energy efficiency and speed, which has greatly contributed to the development of real estate. Thyssenkrupp elevator company has developed a new type of "multiple lift" that can operate vertically. Take the size of a common car The size of the escalator is quite different: but the total area is required in the national standard. Give you a general calculation The width of the well is the width of the car. Well, the depth of the well = the car depth + 600 (for the reside) The width of the well is the width of the car. Well, the depth of the well = the car's depth + 1200 (for the rear-end). The u-shaped tourist ladder is usually around 1000kg The car is usually about 1300x1800 The steel structure shaft is width between 2200 and 2400, depending on the size of the door. The depth of the structure is about 1500, and the rear wall is empty.

- Q: How large a leakage protector is used for the construction elevator

- If it is 33KW, direct start, single cage, 160A, leakage action current 50ma-75ma, movement time 0.1 s, electrical machine leakage protector. The best.

- Q: What are the necessary steps and checks required to maintain a building hoist to ensure its safe and efficient operation?

- <p>Building hoists require regular maintenance to ensure safety and efficiency. This includes daily inspections of the hoist's mechanical and electrical components for any signs of wear or damage. Monthly, a thorough inspection should be conducted by a qualified technician, including checking the hoist's cables, brakes, and safety devices. Lubrication of moving parts and replacement of worn components are also crucial. Annually, a comprehensive inspection and certification by a professional is necessary to comply with safety regulations. Adherence to the manufacturer's guidelines is essential, and any malfunctions should be addressed immediately to prevent accidents.</p>

- Q: What types of materials can be transported using a building hoist?

- <p>A building hoist can lift a variety of materials, including construction supplies such as bricks, cement, sand, and gravel. It can also transport larger items like steel beams, prefabricated concrete elements, and heavy machinery. Additionally, it is used to move tools, equipment, and sometimes personnel within the construction site. The specific materials that can be lifted depend on the hoist's capacity and the safety regulations in place. It's crucial to ensure that the load does not exceed the hoist's weight limit to maintain safety standards.</p>

- Q: This question asks for the cost of a building hoist, which is a type of construction equipment used for lifting materials.

- <p>The cost of a building hoist can vary significantly depending on factors such as the hoist's capacity, type, and features. On average, a basic building hoist can cost anywhere from $10,000 to $50,000. However, for more advanced models with higher capacities or additional safety features, the price can range from $100,000 to $200,000 or even more. It's important to consider the specific needs of your construction project and consult with equipment suppliers for accurate pricing.</p>

Send your message to us

Building Hoist SC200/200B Construction Hoist high Quality

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords