Building Hoist Mast Section with 6.4ton Capacity.

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Building Hoist Description

The hoist can be widely used in industrial and civilian construction, bridge, under well, big chimney as well as shipping industry to carry people and materials. As permanent or semi-permanent equipment, hoist can be used in different sites such as warehouse, high tower, etc.

With the advantages of reliable performance, safety, easy carrying, high adaptability, it can reduce operators’ work intensity.

With many advanced technology integrity, strict control on each making process, high ratio of price and quality, CMAX hoist has become a symbol of lifter with high quality and excellent after-sales service.

Packaging & Delivery of Building Hoist

Packaging: nude and wooded box Delivery: 25-30days

Mains Parts of Building Hoist

1.Metal structure including the mast, tie in and cabin ,could be spay-painted and hot galvanized. Mast section is produced with high quality Q345B seamless steel pipe.

2.Electric parts are all equipped with Schneider , Siemens and other top brands.

3.The electrical system can be adopted with the normal control method and VVVF+PLC control method. Inverter we adopted is from Schneider. Yaskawa and other world famous brand.

4.Cabin exit door adopts ramping type. The ramping door likes a bridge between the building hoist and construction building.

5.The cabin floor is produced from 3MM thickness steel riffled board(Hot dip galvanized), and 15MM thickness wooden board which can reduce the vibration and deformation a lot.

6.Driving unit is adopted the products from ZHANGJIANG and other reputed maker, or from SEW, NORD.

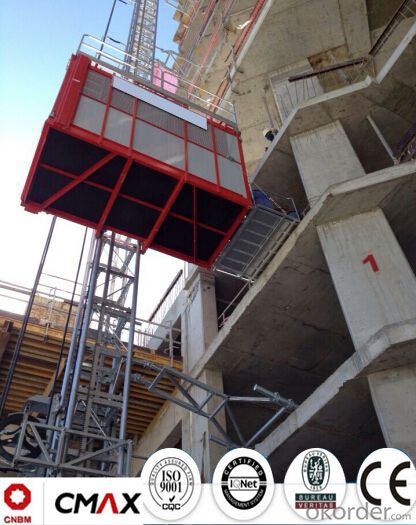

Building Hoist Images

Building Hoist Specification

FAQ of Building Hosit

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: This question asks whether a building hoist can develop operational issues due to incorrect usage or lack of maintenance.

- <p>Yes, a building hoist can malfunction due to improper use or inadequate maintenance. Improper use may include overloading the hoist, using it in unsuitable conditions, or operating it without proper training. Inadequate maintenance can lead to wear and tear, lubrication issues, and component failures. Regular inspections, proper usage guidelines, and timely repairs are crucial to prevent malfunctions and ensure the safety of the hoist and its operators.</p>

- Q: Is it safe to use a building hoist for lifting heavy objects when there is wind?

- <p>Using a building hoist in windy weather is generally not recommended due to the increased risk of accidents. Wind can cause the hoist to sway, potentially leading to loss of control and dropping of the load. Safety guidelines typically advise against hoisting operations when wind speeds exceed certain limits, often around 20-30 miles per hour (32-48 kilometers per hour). It's crucial to check local regulations and the manufacturer's guidelines for the specific hoist model to determine safe operating conditions. Always prioritize safety and ensure that all necessary precautions are taken to secure the load and the hoist in windy conditions.</p>

- Q: This question asks for the steps or procedures to keep a building hoist in good working condition.

- <p>Maintaining a building hoist involves regular inspections, lubrication, and repairs. Ensure all safety features are operational and that the hoist is clean and free of debris. Check cables for wear and replace them if necessary. Lubricate moving parts as per the manufacturer's recommendations. Inspect the electrical system for any signs of damage or wear. Regularly test the hoist's load capacity and emergency stop functions. Keep a maintenance log to track all inspections and repairs. If any issues are identified, address them promptly to prevent accidents and ensure the hoist operates safely and efficiently.</p>

- Q: What is the main function of the construction elevator safety guard

- Falling to a certain speed will automatically card death

- Q: This question asks about the procedures and practices for regularly maintaining and inspecting a building hoist to ensure its safe and efficient operation.

- <p>Regular maintenance and inspection of a building hoist are crucial for safety and efficiency. It involves daily checks before use, including visual inspections for any visible damage, proper functioning of safety devices, and ensuring the hoist is clean and free of debris. Weekly inspections should focus on the mechanical components, such as gears, cables, and brakes, and checking for any unusual noises or vibrations. Monthly inspections may include more in-depth checks of the electrical systems and the structural integrity of the hoist. Annual inspections typically involve a thorough examination by a certified professional, who will assess the overall condition and safety of the hoist, ensuring it complies with all relevant safety standards. Always follow the manufacturer's guidelines and local regulations for maintenance and inspection schedules.</p>

- Q: Is the construction elevator a special equipment

- The construction elevator is a special equipment. Special equipment is related to life safety, greater danger of boilers, pressure vessels (including gas cylinders), pressure pipes, elevators, lifting machinery, passenger ropeway, large-scale amusement facilities and field special motor vehicles (factory) in these eight types of equipment. In order to guarantee the safe operation of the special equipment, the state of all kinds of special equipment, in three stages: from the production, use, the examination has strict rules, is a whole process supervision. According to a 2013-2017 China special equipment inspection testing industry market foresight strategic planning and investment analysis report statistics, by the end of 2011, the national special equipment comprehensive inspection agency has reached 545, including quality inspection department inspection institutions, industry inspection institutions and enterprises self-checking, in addition to type testing institutions, nondestructive testing institutions, cylinder inspection institutions, etc.

- Q: What are the financial expenses associated with buying and keeping a building hoist in good condition?

- <p>The costs of purchasing and maintaining a building hoist include the initial purchase price, which can range from $10,000 to $50,000 depending on the hoist's capacity and features. Maintenance costs involve regular inspections, lubrication, and part replacements, averaging around $1,000 to $3,000 per year. Operating costs include labor for hoist operation and potential rental fees if the hoist is not owned. Additionally, there may be costs for safety training and compliance with regulations. These costs can vary widely based on the specific hoist model, usage frequency, and local regulations.</p>

- Q: Identify the elements that influence the durability and operational lifespan of lifting machinery, specifically focusing on Building Hoists.

- <p>The lifespan of lifting equipment, including Building Hoists, is influenced by several factors: 1) Material Quality: The type and quality of materials used in construction directly affect durability and resistance to wear and tear. 2) Design and Engineering: Proper design ensures optimal performance and reduces stress on components. 3) Frequency of Use: More frequent use can lead to faster wear and tear. 4) Maintenance and Repair: Regular maintenance can extend the lifespan, while neglect can shorten it. 5) Operating Conditions: Environmental factors such as temperature, humidity, and exposure to corrosive substances can impact longevity. 6) Load Capacity: Overloading can cause premature failure. 7) Compliance with Safety Standards: Adhering to safety guidelines can prevent accidents and damage. 8) Technological Advancements: Newer models may have improved features that extend lifespan.</p>

- Q: Explain the distinctions between electric and electric-motorized building hoists.

- <p>Electric building hoists are powered by electricity and typically use a motor to lift and lower loads. They are designed for vertical transport of materials in construction settings. Electric-motorized hoists, on the other hand, are a specific type of electric hoist that emphasizes the use of an electric motor for operation. The primary difference lies in the level of automation and control. Electric-motorized hoists often have more advanced features like variable speed control and may be integrated into larger systems for automated material handling. Both are efficient, but electric-motorized hoists offer higher precision and control, making them suitable for more complex applications.</p>

- Q: What are the expenses involved in buying and maintaining a building hoist?

- <p>The costs of purchasing and operating a building hoist include the initial purchase price, which can range from $10,000 to $50,000 depending on the model and capacity. Operating costs involve maintenance, which may be around $1,000 to $5,000 per year, and electricity for operation, which can vary based on usage. Additionally, there may be costs for installation, insurance, and potential repairs. Labor costs for operating the hoist should also be considered, as well as costs for compliance with safety regulations. These costs can vary widely based on location, the specific hoist model, and the scale of operations.</p>

Send your message to us

Building Hoist Mast Section with 6.4ton Capacity.

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords