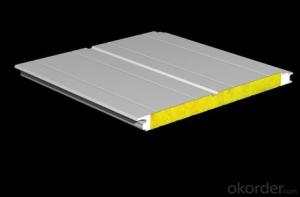

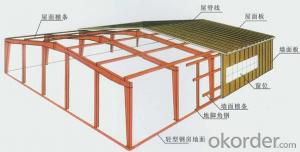

Honeycomb Sandwich Panels - Fireproof EPS Building Construction Material for Exterior Walls

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | pieces in pallets and pallets in container for fireproof eps sandwich panels |

| Delivery Detail: | Three weeks after down payment |

Specifications

fireproof eps sandwich panels

-Factory price

-Heat preservation

-SGS/CE certificate

Building construction material fireproof eps sandwich panels for exterior wall

Product Description

Brief Introduction of eps sandwich panels :

Our fireproof eps sandwich panels is made from fiber reinforced cement board

(medium density), natural quartz, polystyrene particles, light weight portland cement

and many additives, etc, which takes fiber reinforced cement board as its surface panel.

It can be widely applied to interior and exterior non-bearing walls.

Product technical data of eps sandwich panels :

Item | Unit | 150mm | 125mm | 100mm | 75mm | 50mm |

Dry Shrinkage | mm/m | 0.35 | 0.35 | 0.36 | 0.35 | 0.36 |

Sound Insulation | dB | ≥52 | ≥50 | ≥46 | ≥46 | / |

Anti-impact | Times of no through cracking | 10 | 10 | 10 | 10 | 5 |

Destroy Loading | The multiple of the board’s self-weight (loading) | 3.5 | 3.5 | 4 | 4.5 | 4.2 |

Compressive Strength | Mpa | 3.6 | 3.6 | 3.7 | 3.7 | 4.2 |

Hanging Strength | N | 1000 | 1000 | 1000 | 1000 | 800 |

Fire Rating | H | ≥3 | ≥3 | ≥3 | ≥2 | 1 |

Heat Transfer Coefficient | W(m2·K) | 1.45 | 1.25 | 1.25 | - | - |

Water Contain | % | 10 | 10 | 10 | 10 | 10 |

Moisture-proof | Moisture-proof | |||||

In-Combustibility | GB8624-2006 Grade A1 | |||||

Resistance to Halide | Moisture-proof &Halide Resist | |||||

Gas-proof and Anti-moth | Inorganic substances have insect-resistant, gas-proof anti-moth performance. | |||||

- Q: Will the Yanmian sandwich panels do external wall insulation wall can paste tiles? Do A-class insulation of the external wall insulation materials can be posted what kind of it?

- Single row of scaffolding, that is, the entire frame by a row of pole composition; due to its small range (generally only used in decorative construction), poor stability, erection height is small, has gradually withdrawn from the construction market

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- It should be, for example, naphthalene anthracene, and several rings are capable of forming a closed conjugate system. Generally speaking, more than four benzene rings are fused (for example, 1.2-benzo, 3-methyl Anthracene, etc.) are mostly carcinogenic substances, which are mostly anthracene derivatives, the relationship between the mechanism of carcinogenesis and structure is not yet fully understood ...

- Q: What is the difference between the board and the core board? The The

- 024 (thermal conductivity of the lower insulation effect The better) Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation The cost is still lower than the infusion process

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- The wall is relatively smooth, the external wall insulation per square meter with the mortar 4-foot often end of the shop to the whole shop 6 kg foot; wall is the wall, more mortar, a square need 7-9 kg

- Q: Color steel sandwich panels and color steel plate What is the difference

- Excuse me, where are you in? Indoor insulation is generally made of "polystyrene foam board", the general thickness is 2..3 cm thick, you can understand clearly, in the end is how thick the foam board (when playing screw holes, can be found is thick thick foam board) The There is that you can use .7 inside the expansion screw, to the hardware store to find can match. You can also use welding, then a long screw, is also very simple.

- Q: What is the quota of the demolition of the color steel plate?

- Answer: safety production laws and regulations, including safety in production (BE) A

- Q: 800 * 800 tiles can not stick to the sandwich panel on the wall to do

- Wall insulation is an important part of the work of home insulation, divided into external wall insulation and internal wall insulation two, the amount of internal wall insulation works much smaller than the external wall insulation, Xiaobian today to share the advantages and disadvantages of various interior wall insulation materials The Polystyrene foam board polystyrene foam board is one of the three common wall insulation materials

- Q: Can sandwich panels be used for ticket booths?

- Yes, sandwich panels can be used for ticket booths. Sandwich panels are made up of two thin outer layers with a thermal insulating core material in between. They are known for their strength, durability, and energy efficiency. These properties make them an ideal choice for various construction applications, including ticket booths. Sandwich panels can provide insulation against extreme temperatures, noise reduction, and fire resistance, which are important features for ticket booths. Additionally, sandwich panels are lightweight, making them easy to transport and install. They can also be customized to fit specific design requirements and can be easily maintained. Therefore, sandwich panels are a suitable and practical option for ticket booths.

- Q: Are sandwich panels suitable for retail outlets?

- Yes, sandwich panels are suitable for retail outlets. Sandwich panels are made of two layers of rigid material with a core material in between. The rigid layers provide strength and durability, while the core material provides insulation and soundproofing properties. In a retail outlet, sandwich panels can be used for various purposes. They can be used as exterior cladding for the building, providing a sleek and modern look. The panels can also be used for interior walls and partitions, creating separate spaces within the store. Sandwich panels are easy to install and can be customized to fit the specific requirements of the retail outlet. They can be painted or decorated to match the branding and aesthetics of the store. Additionally, sandwich panels are lightweight and can be easily transported and assembled, making them a cost-effective choice for retail outlets. Furthermore, sandwich panels offer excellent thermal insulation, helping to keep the store cool in summer and warm in winter. This can lead to energy savings and a comfortable shopping environment for customers. Overall, sandwich panels are a suitable choice for retail outlets due to their durability, versatility, and energy-efficient properties. They provide an attractive and functional solution for both the exterior and interior of the store.

- Q: Steel structure workshop roof load is the number of specific Please thank you

- Contents The first chapter of the construction site safety technical information management of the main contents and requirements Section I construction site safety technical information management of the meaning of Section II of the construction site safety technology management system Section III construction site safety technical information Four sections of the construction site safety technical information classification The second chapter of the construction site safety management information Section I in progress construction safety supervision and related documents (the first file box) Section II safety production responsibility system (the second file box) third (The third file box) Section IV of the safety of the construction organization design (the fourth file box) Section V Division (sub-project) Safety Technology to the end of the (fifth file box) Section VI security check (sixth file Box) Section VII of the safety education (the seventh file box) Section VIII of the pre-class security activities (eighth file box) Section IX special operations certificates (ninth file box) Section X accident (the tenth file box ) Section XI Safety signs (eleventh file box) Section XII security equipment and machinery and equipment related to the management of documents (the twelfth file box) thirteenth Machinery and equipment, facilities acceptance test records (thirteenth file box) Section XIV construction of temporary electricity (the fourteenth file box) Section fifteenth civilized construction (fifteenth file box) trade union labor protection information

Send your message to us

Honeycomb Sandwich Panels - Fireproof EPS Building Construction Material for Exterior Walls

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords