Buidling Hoist Middle Speed Varous Frequency Drive

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Building Hoist Description

Condition: New

Application: Construction

Payload(kg):3200

Lifting Speed(m/min):0~60

Motor Power(kw): 3*22

Safety Device: SAJ50-1.4

Cage: Single

Counterweight: No

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: Type:SC320

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package

Delivery Detail: 25-30days

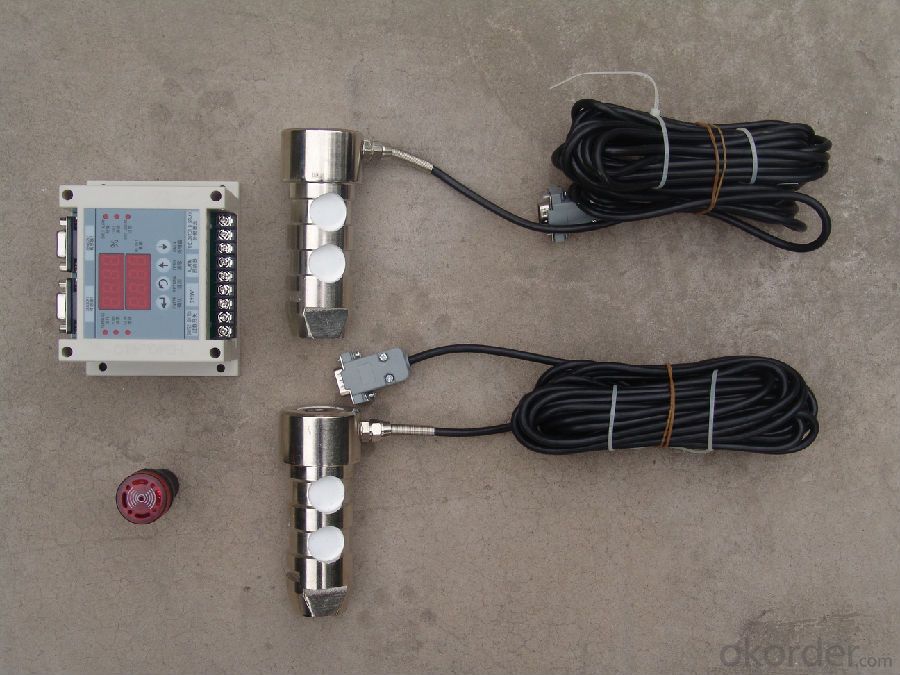

Building Hoist Images

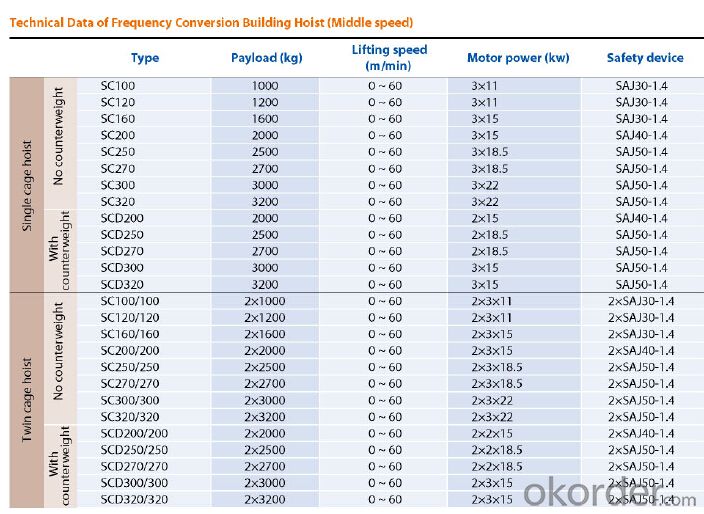

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: Is there any violation of the law after the construction elevator is scrapped?

- Wire rope derrick type: 5 years Gear rack: 8 years After the accident, the person in charge will be unlucky

- Q: This question asks whether a building hoist can develop operational issues due to incorrect usage or lack of maintenance.

- <p>Yes, a building hoist can malfunction due to improper use or inadequate maintenance. Improper use may include overloading the hoist, using it in unsuitable conditions, or operating it without proper training. Inadequate maintenance can lead to wear and tear, lubrication issues, and component failures. Regular inspections, proper usage guidelines, and timely repairs are crucial to prevent malfunctions and ensure the safety of the hoist and its operators.</p>

- Q: This question asks for a list of various types of lifting equipment commonly used in the construction industry.

- <p>In construction, various types of lifting equipment are utilized to move heavy materials and structures. These include cranes such as tower cranes, mobile cranes, and crawler cranes, which are versatile and can lift heavy loads to significant heights. Forklifts are used for lifting and moving materials over short distances. Telescopic handlers, also known as cherry pickers, provide both lifting and access capabilities. Hoists are used for lifting smaller loads and are often found in workshops or on construction sites. Derricks are fixed structures used for lifting heavy loads in a specific area. Lifting slings and shackles are used in conjunction with cranes and hoists to secure loads. Finally, aerial work platforms, like scissor lifts and boom lifts, provide elevated access for workers and materials. Each type of lifting equipment serves a specific purpose and is chosen based on the nature of the construction project and the weight and size of the loads to be moved.</p>

- Q: Is it possible to utilize a single-rope lift as an alternative to a building hoist for the purpose of lifting materials or individuals?

- <p>While theoretically possible to use a single-rope lift for lifting materials or people, it is not advisable or practical for construction purposes. Building hoists are specifically designed for construction sites, offering safety features, load-bearing capacities, and stability that single-rope lifts typically lack. Single-rope lifts are more suited for simple, controlled environments and are not equipped to handle the heavy loads, frequent use, or varied conditions of a construction site. The use of a building hoist is recommended for safety, efficiency, and compliance with construction regulations.</p>

- Q: Why is the construction elevator open on one side and the other on the other

- Double door is feeding door, double door to the outside of the other's role is to prevent someone broke into the cage after elevator start circle accident, because outside over the door of the cage has a travel switch, when someone will ring into the cage opened the cage door, travel switch action at this moment, the elevator power cuts, you won't get elevator lay down this kind of thing. The door is open only when the lift is off the ground, as is said upstairs.

- Q: Is it possible to utilize a single-rope lifting system in both indoor and outdoor environments, especially during cold weather?

- <p>Yes, a single-rope lifting system can be used both indoors and outdoors, including in cold weather conditions. However, it's crucial to consider the specific requirements and limitations of the system and the environment. Cold temperatures can affect the strength and flexibility of the rope, as well as the performance of other components like motors and hydraulic systems. It's essential to use appropriate materials designed for low-temperature operation, ensure proper maintenance, and follow safety guidelines to prevent damage or accidents. Always consult the manufacturer's recommendations for operating in extreme weather conditions.</p>

- Q: This question asks for criteria or factors to consider when selecting the appropriate type of building hoist for a specific construction project.

- <p>Choosing a suitable type of building hoist involves considering several factors: the weight and size of materials to be lifted, the frequency of hoisting, the height of the building, and safety requirements. Assess the load capacity needed, as hoists vary in their lifting capabilities. Consider the hoist's speed and efficiency to ensure it meets the project's timeline. The hoist's size and maneuverability are crucial for fitting within the construction space. Safety features and certifications should be verified to ensure compliance with industry standards. Consulting with hoist manufacturers or rental companies can provide insights into the most suitable hoist for your specific application.</p>

- Q: This question asks about the different types of hydraulic cylinders that are utilized in lifting equipment.

- <p>Hydraulic cylinders used in lifting equipment can be categorized into several types based on their design and application. The main types include: single-acting cylinders, which have one port for fluid and rely on the load or a spring to return; double-acting cylinders, which have ports on both ends and can extend and retract through fluid pressure; telescopic cylinders, which consist of multiple stages that can extend sequentially for greater reach; and rotary hydraulic cylinders, which provide a combination of linear and rotary motion. Each type is chosen based on the specific requirements of the lifting task, such as the need for speed, force, and control.</p>

- Q: What specific regulations or conditions must be met when utilizing lifting equipment in construction or factory environments?

- <p>Yes, there are special requirements for using lifting equipment in construction sites and factories. These include adherence to safety regulations, regular maintenance and inspection, proper operator training, and ensuring the equipment is suitable for the task. Compliance with local and national laws such as OSHA in the U.S. or CE marking in the EU is crucial. Equipment must be certified safe for use, and operators must be licensed and follow safety protocols. Additionally, load capacities must be respected, and lifting operations must be planned and supervised to prevent accidents.</p>

- Q: This question asks whether a building hoist can be utilized for lifting both fragile and non-fragile items.

- <p>Yes, a building hoist can be used for lifting both fragile and non-fragile objects. However, it is crucial to ensure that the hoist is equipped with the appropriate attachments and safety measures to handle fragile items without causing damage. For non-fragile objects, the hoist can be used more freely, but still, safety protocols must be followed to prevent accidents. The key is to use the hoist within its weight capacity and to adhere to all operational guidelines to ensure the safe and effective lifting of all types of objects.</p>

Send your message to us

Buidling Hoist Middle Speed Varous Frequency Drive

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords