Buidling Hoist Vertical Direction Transportation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Building Hoist Description

Condition: New

Application: Construction

Payload(kg):3200

Lifting Speed(m/min):0~60

Motor Power(kw): 3*22

Safety Device: SAJ50-1.4

Cage: Single

Counterweight: No

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: Type:SC320

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package

Delivery Detail: 25-30days

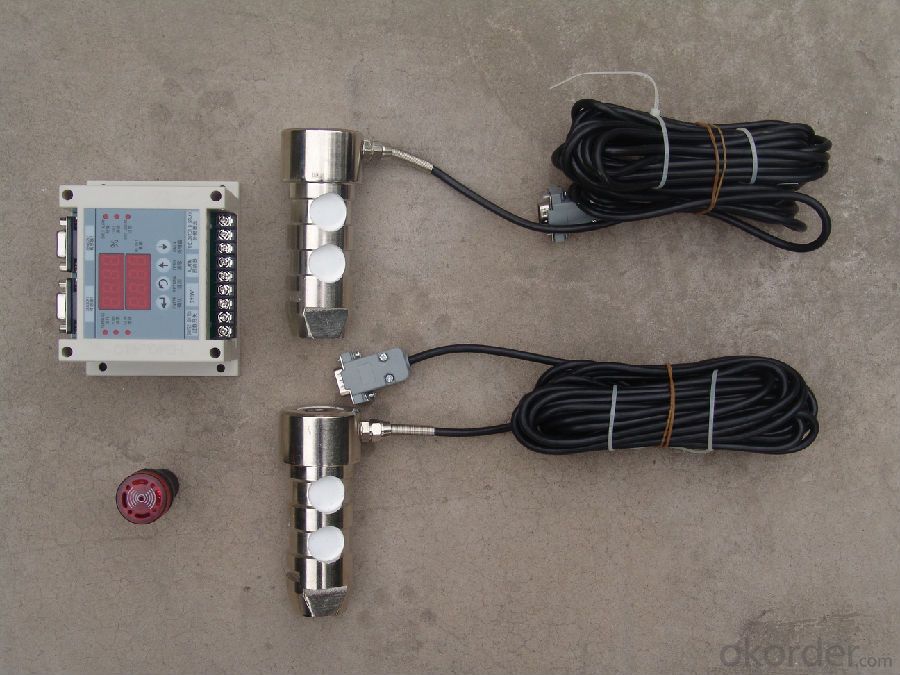

Building Hoist Images

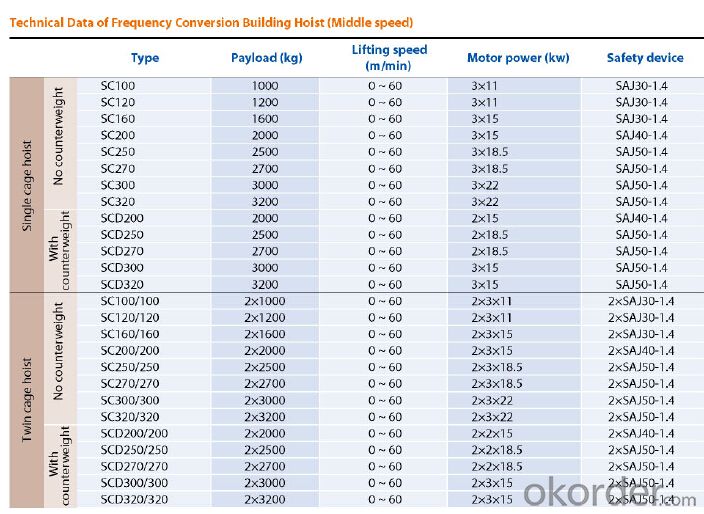

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: Is it possible to use a manual building hoist to lift multiple objects simultaneously?

- <p>Yes, a manual building hoist can be used to lift multiple objects at once, provided the total weight does not exceed the hoist's maximum load capacity. It's crucial to ensure that the hoist is securely attached to a stable structure and that all safety protocols are followed to prevent accidents. The objects should be evenly distributed and properly secured to the hoist to maintain balance and prevent tipping. Always refer to the manufacturer's guidelines for specific weight limits and safety instructions.</p>

- Q: Is it possible to utilize a single-rope lifting system in both indoor and outdoor environments, especially during cold weather?

- <p>Yes, a single-rope lifting system can be used both indoors and outdoors, including in cold weather conditions. However, it's crucial to consider the specific requirements and limitations of the system and the environment. Cold temperatures can affect the strength and flexibility of the rope, as well as the performance of other components like motors and hydraulic systems. It's essential to use appropriate materials designed for low-temperature operation, ensure proper maintenance, and follow safety guidelines to prevent damage or accidents. Always consult the manufacturer's recommendations for operating in extreme weather conditions.</p>

- Q: What are the pros and cons of utilizing hydraulic fluid within the system of a building hoist?

- <p>The advantages of using hydraulic fluid in a building hoist include smooth and controlled lifting, which reduces the risk of accidents. It also offers a compact design due to the high power-to-weight ratio of hydraulic systems. Additionally, hydraulic systems are known for their durability and low maintenance requirements. However, there are disadvantages such as the potential for leaks, which can be hazardous and costly to repair. The systems can also be sensitive to temperature changes, which might affect performance. Lastly, hydraulic fluids can be environmentally harmful if not properly managed, posing disposal challenges.</p>

- Q: A lift motor is 7.5 KW, and the frequency converter sends current 4.2 A, which has A heating resistance in the converter, and how the charge is calculated when the lift is full. Or consider the power of the converter and the power of the thermal resistance.

- Use electricity in the field (1) lifting equipment class: tower crane 2, construction elevator 3; According to the table, K = 0.3 cos phi = 0.7 tg phi = 1.02 JC = 40% (temporary load) Pe = 2 times 63 + 3 times 11 = 159 (kW) And then power: PS = 2 times Pe = 2 times 159 = 201 (kW) Pjs1 = K * PS = 0.3 * 201 = 60.3 (kW) Qjs1 = tg phi by Pjs1 = 1.02 times 60.3 = 61.5 (kVA)

- Q: This question asks for the steps or process involved in installing a building hoist, which is a type of crane used in construction to lift materials.

- <p>Installing a building hoist involves several steps: 1) Site preparation, ensuring the ground is level and strong enough to support the hoist. 2) Assembling the hoist tower, starting from the base and working upwards. 3) Installing the motor and drive system. 4) Attaching the cable and counterweight. 5) Rigging the hoist with safety devices and load limiters. 6) Conducting a thorough inspection and testing the hoist for safety and functionality. 7) Obtaining any necessary permits and approvals. It's crucial to follow the manufacturer's instructions and local regulations, and often requires a professional team for safe and proper installation.</p>

- Q: Where is the location of the elevator in the project

- The position of construction elevator is usually set in the project to facilitate access to material, material handling and personnel up and down, not affecting the construction process.

- Q: Can a building hoist be utilized for lifting objects that exceed manual lifting capabilities?

- <p>Yes, building hoists are specifically designed to lift and transport objects that are too large or heavy for manual lifting. They are commonly used in construction to move materials and equipment to various levels of a building. Building hoists are equipped with safety features and can handle substantial weight, making them an essential tool in construction projects where heavy objects need to be moved efficiently and safely.</p>

- Q: This question asks for methods to prevent leakage in hydraulic cylinders used in building hoists.

- <p>To prevent hydraulic cylinder leaks in a building hoist, follow these steps: Regularly inspect and maintain the hydraulic system to ensure all seals and gaskets are in good condition. Replace any worn or damaged components promptly. Ensure the hydraulic oil is clean and at the correct level to avoid air bubbles or cavitation which can cause leaks. Check the cylinder rods for scratches or damage and polish or replace them if necessary. Maintain the correct operating pressure and avoid overloading the hoist. Regularly lubricate moving parts to reduce friction and wear. Implement a routine maintenance schedule to catch and address potential issues before they lead to leaks.</p>

- Q: This question asks for guidelines on the safe operation of a building hoist, a device used to lift materials in construction.

- <p>To use a building hoist safely, follow these guidelines: Ensure the hoist is properly installed and inspected by a qualified person. Never exceed the hoist's weight limit. Keep the hoist area clear of obstacles and ensure all safety devices are functioning. Do not use the hoist if there are any visible defects or damage. Always secure the load properly and ensure it is balanced. Never leave the hoist unattended while in operation. Use hand signals or a communication system to coordinate with the operator. Regularly inspect and maintain the hoist to prevent accidents. Always follow the manufacturer's instructions and adhere to local safety regulations.</p>

- Q: Is it possible to employ a building hoist for demolition purposes?

- <p>While a building hoist is primarily designed for construction purposes, such as lifting materials and personnel to different floors, it is not typically recommended for demolition work. Demolition requires specialized equipment that can handle the specific stresses and hazards associated with breaking down structures. Using a building hoist for demolition could be dangerous and may not comply with safety regulations. It's crucial to use equipment specifically designed for demolition tasks to ensure the safety of workers and the effectiveness of the operation.</p>

Send your message to us

Buidling Hoist Vertical Direction Transportation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords