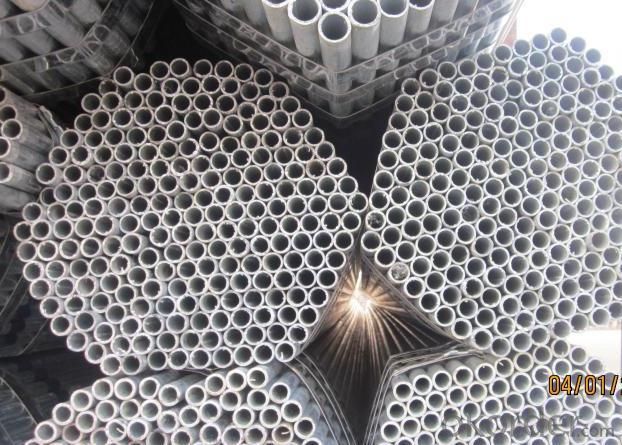

BS 1387 Hot Dipped Galvanized Pipe

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery of BS 1387 Hot Dipped Galvanized Pipe:

Package:BS 1387 Hot dipped galvanized steel pipe in bundles acc to bs standard

Delivery:30-50days

Specification of BS 1387 Hot Dipped Galvanized Pipe:

| Thickness: | 0.7 - 8.18 mm | Section Shape: | Round | Outer Diameter: | 21 - 219 mm |

| Place of Origin: | Tianjin China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Structure Pipe |

| Technique: | ERW | Certification: | BSI | Surface Treatment: | Galvanized |

| Special Pipe: | Thick Wall Pipe | Alloy Or Not: | Non-alloy | Name: | BS 1387 Hot dipped galvanized steel pipe |

| Usage: | construction or water project,fence | C/O: | FORM E FORM A | Quality: | Prime Quality |

| Grade: | Q235,Q345,Q195-Q345 | Standard: | BS 1387,BS 1139,BS 4568,BS EN10219,JIS G3444-2006 |

Application of BS 1387 Hot Dipped Galvanized Pipe:

Widely used as the pipeline of industrial and civilian water, air, petroleum, natural gas, communication and so on.

- Q: What is the maximum diameter of steel pipes?

- The maximum diameter of steel pipes can vary depending on various factors such as manufacturing capabilities, industry standards, and specific project requirements. However, steel pipes can typically range from a few millimeters in diameter for small-scale applications to several meters in diameter for large-scale industrial projects.

- Q: What is the difference between seamless steel pipes and seamless stainless steel pipes?

- The main difference between seamless steel pipes and seamless stainless steel pipes lies in their composition. Seamless steel pipes are typically made from carbon steel, which is an alloy of iron and carbon. On the other hand, seamless stainless steel pipes are made from an alloy of iron, carbon, and chromium, which gives them enhanced corrosion resistance and durability. This makes seamless stainless steel pipes suitable for applications where resistance to corrosion is essential, such as in the food industry or in environments with high humidity or exposure to chemicals.

- Q: How are steel pipes insulated to prevent freezing?

- Steel pipes are commonly insulated to prevent freezing by applying a layer of insulation materials, such as foam or fiberglass, around the pipes. This insulation helps to maintain the temperature of the pipes and prevents heat loss, thus preventing the water inside from freezing during cold weather conditions. Additionally, heat tracing cables can be used along with the insulation to provide an extra layer of protection by supplying heat to the pipes.

- Q: What are the different methods of joining steel pipes?

- There are several different methods of joining steel pipes, including threaded connections, weld connections, flanged connections, and grooved connections. Each method has its own advantages and is suited for different applications. Threaded connections involve screwing the pipes together using threads on the ends of the pipes. Weld connections involve fusing the ends of the pipes together through welding. Flanged connections involve using a flange on each end of the pipe and bolting them together. Grooved connections involve using grooves on the ends of the pipes and connecting them with coupling fittings.

- Q: What are the advantages of using steel pipes in the manufacturing of storage tanks?

- There are several advantages of using steel pipes in the manufacturing of storage tanks. Firstly, steel pipes are known for their strength and durability, making them suitable for holding large volumes of liquids or gases. They can withstand high pressure and extreme weather conditions, ensuring the longevity of the storage tank. Additionally, steel pipes are resistant to corrosion, which is crucial for preventing leaks or contamination of the stored materials. Moreover, steel pipes can be easily welded, allowing for efficient and precise construction of storage tanks. Finally, steel pipes have a high recyclability rate, making them an environmentally friendly choice for storage tank manufacturing.

- Q: Are steel pipes suitable for wastewater treatment plants?

- Yes, steel pipes are suitable for wastewater treatment plants. Steel pipes are commonly used in wastewater treatment plants due to their high strength and durability. They can withstand high pressure and are resistant to corrosion, making them ideal for carrying wastewater and other fluids in the harsh conditions found in treatment plants. Additionally, steel pipes can be easily welded and joined, allowing for flexibility in the design and installation of the piping system. Overall, steel pipes are a reliable and cost-effective choice for wastewater treatment plants.

- Q: How are steel pipes used in the manufacturing of structural frameworks?

- Steel pipes are commonly used in the manufacturing of structural frameworks due to their strength, durability, and versatility. These pipes are used as components in the construction of frameworks, such as buildings, bridges, and towers, providing support and stability to the overall structure. Steel pipes are often used to create columns, beams, and trusses, which are essential for bearing heavy loads and ensuring the structural integrity of the framework. Additionally, steel pipes can be easily welded, allowing for efficient and cost-effective construction processes. Overall, steel pipes play a crucial role in the manufacturing of structural frameworks by providing a robust and reliable solution for various construction projects.

- Q: What are the different methods of pipe support for steel pipes?

- Various methods exist for supporting steel pipes, each aimed at guaranteeing pipe stability, alignment, and protection. Some frequently employed techniques are as follows: 1. Pipe Hangers: These devices suspend or bear the weight of the pipe from above. Typically crafted from metal, they can be adjustable or fixed, allowing for easy installation and maintenance. Depending on the application, pipe hangers can take the form of clevis hangers, beam clamps, or pipe rollers. 2. Pipe Shoes: These supports attach directly to the underside of the pipe, providing a stable resting surface. Usually made from steel or other durable materials, pipe shoes prevent pipe movement, absorb vibrations, and distribute weight evenly. They find common use in applications involving high temperatures or requiring thermal expansion. 3. Pipe Clamps: These devices fasten pipes together or secure them to structures. Constructed primarily of metal, pipe clamps come in various sizes and designs to accommodate different pipe diameters and configurations. They provide support and prevent sagging or movement, particularly in areas with directional or elevation changes. 4. Pipe Racks: These structures are custom-designed to support multiple pipes in an organized and secure manner. Commonly found in industrial settings like refineries or power plants, pipe racks store or support large quantities of pipes. Typically made of steel, they can be tailored to suit different pipe sizes and layouts. 5. Pipe Guides: These devices facilitate pipe movement control, especially during thermal expansion or contraction. Fixed to the structure, pipe guides offer a sliding surface that accommodates longitudinal pipe movement. They are frequently utilized in applications involving temperature variations, such as steam or hot water systems. These represent just a few examples of the numerous methods available for supporting steel pipes. The choice of support method depends on factors such as pipe size, weight, temperature, and specific application requirements. Selecting the appropriate support method is crucial to ensure pipe longevity and integrity while preventing issues like sagging, misalignment, or failure.

- Q: What are the factors affecting the durability of steel pipes?

- There are several factors that can affect the durability of steel pipes. These include corrosion, temperature fluctuations, mechanical stress, and exposure to chemicals or abrasive materials. Additionally, the quality of the steel used in the pipes, the design and construction of the piping system, and proper maintenance and inspection practices can also impact their durability.

- Q: How are steel pipes used in seaport infrastructure?

- Steel pipes are commonly used in seaport infrastructure for various purposes such as constructing piers, docks, and wharves. They are also used in the construction of offshore platforms and maritime structures like breakwaters and jetties. Steel pipes provide the necessary strength and durability to withstand the harsh marine environment and are used for the transportation of water, fuel, and other fluids within the port. Additionally, they are employed in the construction of pipelines for the loading and unloading of cargo ships, as well as for dredging and marine construction activities.

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 1999 |

| Annual Output Value | Above Thirty Million RMB |

| Main Markets | Main land; Middle East; Southeast Asia |

| Company Certifications | ISO 9001:2011;CE:2010 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 30% - 40% |

| No.of Employees in Trade Department | 101-200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 50,000 square meters |

| No. of Production Lines | Above 14 |

| Contract Manufacturing | Hui Ke Steel Pipe Co,.Ltd |

| Product Price Range | Average |

Send your message to us

BS 1387 Hot Dipped Galvanized Pipe

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords