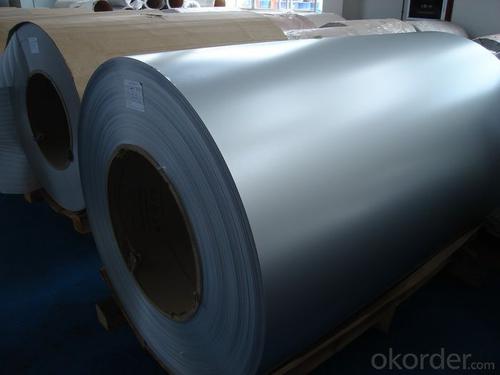

Brushed Nickel Aluminum Coil - Champagne Silver Color Coated

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Featuresof PVDF Aluminum Coil:

1. Adoptingprecision rolling coating technology, our PE coated coil can ensure excellentadhesive without coating omission.

2. For the PVDFcoated aluminum sheet we produced, there are various colors for your choice.

3. Usinginfrared heating technology to protect environment from pollution.

4. Ourcoated aluminum coil has four-roller coating line, uniform coating thicknessand good features.

Raw Materialof the PVDF Coated Aluminum Coil:

1. AluminumCoil: high strength aluminum with alloy of AA1100 (aluminum alloy is availablewith AA3003, AA3005, AA5005 according to customer)

2. SurfacePaint: PE, PVDF and special paints.

Specificationof the PVDF Coated Aluminum Coil:

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

ExternalDiameter: ≤ 1500mm

InternalDiameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

Performance and usage

PVDF coated aluminumcoils are specially processed through the technics of roller coating and bakingwith precise paints from BECKER INDUSTRIAL COATINGS in

Performance of the coating

Aluminum Thickness | Coating Thickness | MEK | T Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥25μm | ≥100 Times | ≤2T | 50kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.28mm | ≥25μm | ≥100 Times | ≤2T | 20kg•cm | 0 Grade | ≥HB | no change within 2 hours |

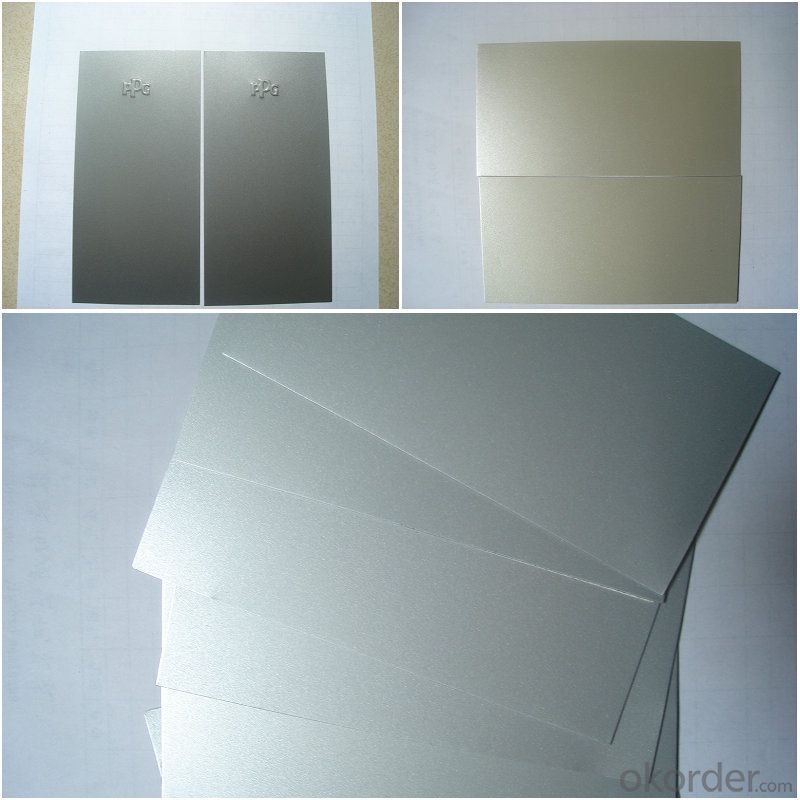

Color ofCard

Our PVDF coated aluminum coil is made offluorine carbon resin, pigment, ester solvent after high temperature roastingand baking. The paint of this PVDF coated aluminum coils are solidified to dryfilm with super weather resistance. PVDF coating also can be classified astraditional PVDF and nanometer PVDF coating.

A. Traditional PVDF Coating, with KYNAR500 PVDF and two or three times forcoating and baking, has good properties of anti-acid, anti-alkali and isdurable in atrocious weather and environment, keeping 15 years no unwontedfading. In view of these facts, we recommend this PVDF coated aluminum coilsare applied for external wall cladding.

B. Nanometer PVDF Coating, which different with traditional PVDF, is the clearcoating. It contains nanometer element, which can protect panel from pollution,because nanometer has self-cleaning effect, it is easy to get rid of dust andpollution by raining or water.

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, soit is suggested all panels are placed in one order for same project. And keepsame direction as arrow on protective film when installing to avoid any colordifference by vision.

- Q: Are there any specific guidelines for the storage of aluminum coils?

- Yes, there are specific guidelines for the storage of aluminum coils. Here are some key considerations: 1. Location: Aluminum coils should be stored in a clean, dry, and well-ventilated area. The storage facility should be free from excessive humidity, direct sunlight, and temperature fluctuations. 2. Handling: Coils should be handled with care to prevent damage. They should be lifted using appropriate lifting equipment to avoid any bending or deformation. 3. Stacking: When stacking aluminum coils, it is important to ensure that they are properly supported to prevent any distortion or collapse. Coils should be stacked horizontally on a flat surface, ideally on pallets or racks, with sufficient space between each coil to allow for ventilation. 4. Protection: Coils should be protected from dust, dirt, and moisture. They should be covered with a suitable protective material, such as plastic sheets or tarpaulins, to prevent any contamination or oxidation. 5. Labeling and organization: It is recommended to label each coil with relevant information, such as the alloy type, size, and production date. This facilitates easy identification and inventory management. Additionally, maintaining an organized storage system helps prevent damage and allows for efficient retrieval. 6. Inventory management: Regular inspection and inventory checks should be conducted to identify any signs of damage or deterioration. Coils should be rotated to ensure proper usage and prevent any prolonged storage that could lead to quality issues. It is important to note that these guidelines may vary depending on the specific requirements of the manufacturer or supplier. Therefore, it is advisable to consult the manufacturer's recommendations or seek professional advice for the storage of aluminum coils.

- Q: How do aluminum coils contribute to sustainable packaging?

- Aluminum coils play a significant role in promoting sustainable packaging practices. Firstly, aluminum is an infinitely recyclable material, meaning it can be recycled repeatedly without losing its properties or quality. This feature enhances the sustainability of packaging as it reduces the need for extracting and processing virgin materials, thereby conserving natural resources and minimizing the environmental impact associated with mining and production. Moreover, aluminum coils offer exceptional barrier properties, effectively protecting the packaged goods from external factors such as moisture, light, and oxygen. This barrier function helps to extend the shelf life of products, reducing food waste and preventing the need for additional packaging or preservatives. By keeping products fresh for longer periods, aluminum coils contribute to sustainable packaging by supporting efforts to combat food loss and promote resource efficiency. Furthermore, aluminum is lightweight, making it an ideal material for packaging. Its low weight allows for reduced transportation costs and energy consumption during shipping, contributing to overall carbon emissions reduction. The lightweight nature of aluminum coils also makes them convenient for end consumers, reducing the environmental impact associated with disposal and recycling. Additionally, aluminum is highly durable and resistant to corrosion, ensuring the integrity of the packaging throughout its lifecycle. This durability means that aluminum coils can be reused or repurposed, further reducing waste and extending the material's lifespan. In summary, the use of aluminum coils in packaging promotes sustainability in multiple ways. It contributes to a circular economy by being infinitely recyclable, reduces food waste through effective barrier properties, lowers carbon emissions through lightweight design, and encourages reuse and repurposing due to its durability. By incorporating aluminum coils into packaging solutions, we can make significant strides towards achieving a more sustainable and environmentally friendly packaging industry.

- Q: Are aluminum coils resistant to UV radiation?

- Generally, aluminum coils have resistance to UV radiation. Aluminum is a material known for its high durability and resistance to corrosion. It possesses innate properties that shield it from the harmful impacts of UV radiation. Unlike some other metals, aluminum does not undergo oxidation or deterioration when exposed to sunlight over long durations. This characteristic renders it an excellent option for applications that involve UV exposure, including outdoor structures, solar panels, and automotive components. Nonetheless, it is crucial to acknowledge that although aluminum can withstand UV radiation, it may still experience degradation if not adequately protected or maintained.

- Q: Are aluminum coils suitable for construction purposes?

- <p>Yes, aluminum coils can be used for construction. They are valued for their lightweight, corrosion resistance, and high strength-to-weight ratio, making them ideal for applications such as roofing, facades, and structural components. Aluminum's malleability allows for easy shaping and forming, which is beneficial in various construction projects. It's also sustainable due to its recyclability, reducing environmental impact.</p>

- Q: I am looking for a good comparison between carbon fiber and aluminum, we presently use aluminum in a lot of our manufacturing and may want to use cf. Does anyone have a simple breakdown of rough cost difference, weight savings, sheet thickness for a certain strength, that kind of thing, kind of struck-out looking on google unless I wanted a bike...Thanks in advance.

- Carbon Fiber. It's the more expensive one, but look at cars for instance. It's light weight, very strong, and great if you're a drifter or racer. I guess it depends on what you're making though.

- Q: My favorite deodorant contains aluminum. It smells really good and it works really well.My mom doesn't like me using it because it contains aluminum.So I got aluminum free. It doesn't smell at all (I can't seem to find fragrant aluminum free deodorant) and it doesn't work as well, for some reason.I want to keep using the one with aluminum, but will it be harmful to me in the future?

- Aluminum, okorder /

- Q: Can aluminum coils be utilized as materials for constructing roofs?

- <p>Yes, aluminum coils can be used for roofing materials. They are known for their durability, corrosion resistance, and lightweight properties, making them an excellent choice for roofing. Aluminum's reflective surface also helps in energy efficiency by reflecting sunlight and reducing heat absorption. It's recyclable and has a long lifespan, which contributes to its sustainability. However, it's important to ensure that the aluminum coils are of the appropriate gauge and quality for the specific roofing application to guarantee structural integrity and performance.</p>

- Q: Is aluminum silicate roll felt the same as aluminum silicate acupuncture blanket?

- No, the unit weight of aluminum silicate fiber felt is greater than that of aluminum silicate acupuncture blanket. Both are thermal insulation and fire-proof material and have the same function.

- Q: A certain ionic compound is made entirely of aluminum and oxygenWhat is the formula for this compound?

- Aluminium Oxide: Al2O3 The ions: Al3+ .............. O2- When they bond: It is ionic as it takes place by the transfer of electrons from Aluminium(metal) to Oxygen(Non-metal). Hence, the bond is: Al2O3, Aluminium Oxide or alumina.

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum coils in food storage.

- <p>Advantages of using aluminum coils for storing food include their excellent heat conductivity, which allows for even heating and cooling, making them ideal for temperature-sensitive food items. They are also lightweight, durable, and resistant to corrosion, which enhances their longevity. Additionally, aluminum coils are recyclable, contributing to environmental sustainability. Disadvantages include potential health concerns due to the leaching of aluminum into food, especially in acidic environments. There's also the risk of denting or scratching the surface, which can compromise the integrity of the coil and lead to contamination. Moreover, aluminum coils may not be suitable for all types of food storage, particularly those requiring airtight or vacuum sealing.</p>

Send your message to us

Brushed Nickel Aluminum Coil - Champagne Silver Color Coated

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords