Maple Plywood WBP Glue and Best Quality LVL Scaffolding Plank/Board for Construction

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 3000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LVL Scaffolding Plank

Laminated Veneer Lumber Scaffolding Board for construction

Features:

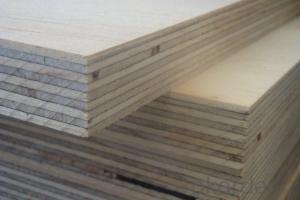

1) Dimensions: length: 1980/2980/2500/3900/3980/5980( length within 12 metres)

width: 220/225/230mm

thickness: 38/39/42mm

we may manufacture kinds of sizes according to clients' requirements.

2) Material: Radiate Pine from New Zealand

3) Adhesive: WBP glue ( Environment Friendly )

4) Produce Ability: 60,000CBM/Year

5) Standard:

We are applying an inspection certification from third party agency, now we are instructed under its China agent.

6) SGS Test Report by according AS 1577-1993

7) Usage:

LVL is used primarily as structural framing for residential and commercial construction and is well suited to applications where open web steel joists and light steel beams might be considered. Others uses include scaffold planking and as flange members for some proprietary prefabricated wood I-Joists. LVL can easily be cut to length at the jobsite.

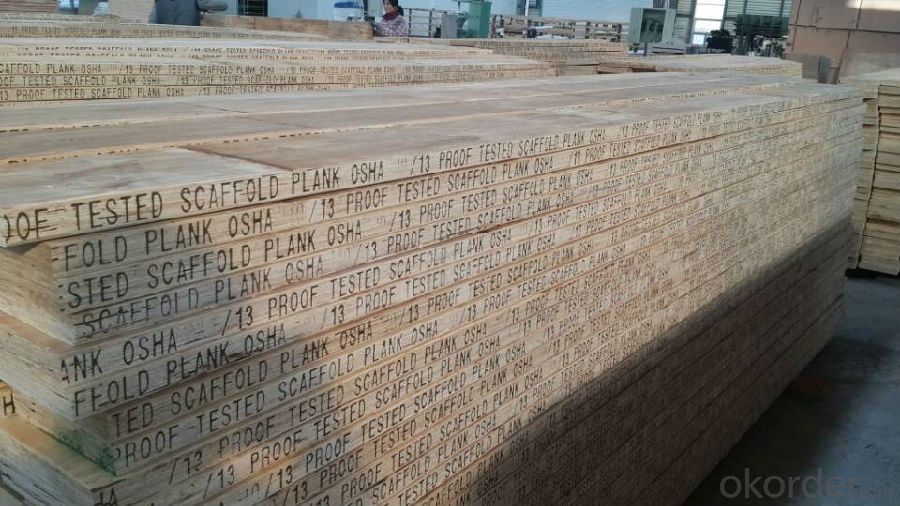

Application: For use as scaffold platforms or decks in accordance with U.S. Department of Labor Regulations (OSHA) or British Standards

Material: Structural laminated veneer lumber (LVL)

Standards: AS/NZS 4357:1995 Structural laminated veneer lumber GB/T 20241- 2006 Standard for laminated veneer lumber ANSI A10.8 – 2001, Safety Requirements for Scaffolding OSHA, Occupational Safety & Health Administration, U.S. Dept. of Labor, Regulations (Standards – 29 CFR) Scaffold Specifications – 1926 Subpart L, Appendix A BS 2482 Specification for Timber Scaffold Boards

Species Used: Plantation forest Radiata Pine

Adhesive & Bond: Phenolic, Type A (WPBP) Bond

Section Size: 38、39、42mm thick x 220、225、230mm wide (Tolerances, -0, +2mm)

Moisture Content: 6% to 18%

Lengths: To customer specification up to 12000mm (Tolerance, -0mm, +10mm)

Approximate Mass: 580kgs/M3

Strength & Stiffness 1) Batch sampling of LVL from production and testing for Verification: Modulus of Elasticity and Modulus of Rupture 2) Boards proof loaded and rigidity measured for verification of strength claims

Edge Branding: OSHA, BS2482, PROOF TESTED SCAFFOLD BOARD, MM/YY

Finish: Unsanded faces, sawn edges, arrisses chamfered (to prevent splintering), ends painted (to inhibit moisture egress/ingress)

- Q: according to the use of plywood can be divided into needle plywood and broadleaf plywood.

- Ⅲ, Ⅳ plywood moisture content of not more than 15%). ③ quality. Finished products should have rectangular straight edges and obvious edges and corners;

- Q: Now what is the market for plywood development?

- has also been greatly improved in the international market more and more competitive. China is not only a large veneer export, or the world's largest plywood producer.

- Q: How do you choose plywood in plywood production?

- Several kinds of said in the "veneer", "slices", "veneer" are reflected in the "plaque" the basic characteristics. But can not be cedar plywood, ash willow plywood and other abbreviations, because these referred to as refers to the plywood panel, the floor by the cedar or Ash made.

- Q: According to the different composition of the glue, for the construction of plywood with the following types of glue

- According to the environmental protection level, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and even E2 level are not reach the unqualified glue)

- Q: Further processing of the plywood

- Pre-finned plywood Prefinisked plywood The manufacturer has been treated with a special table without the need to modify the plywood.

- Q: What types of plywood can be divided into?

- Class I (NQF) - weather resistant, resistant to boiling plywood Class II (Ns) - Water resistant plywood.

- Q: What are the key points for plywood selection?

- panel decoration need to use transparent varnish (also known as oil), to retain the natural color of wood surface and texture, should focus on the panel material, pattern and color selection

- Q: What are the defects of the plywood?

- dead dead knots formed by the dead branches of trees, knots surrounded by the surrounding wood together, or even only part of the length of its cross-section of the length of about 1/4 or less than 1/4 , Texture hard or soft, and sometimes fall off the formation of empty.

- Q: For the plywood environmental advice?

- According to the environmental protection level, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and even E2 level are not reach the unqualified glue)

- Q: The usual length and width specifications are:

- The main tree species are: camphor, willow, poplar, eucalyptus and so on. The main origin of plywood: Indonesia and Malaysia.

Send your message to us

Maple Plywood WBP Glue and Best Quality LVL Scaffolding Plank/Board for Construction

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 3000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords