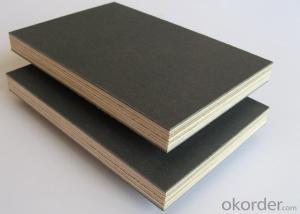

Plywood 1 2 Inch Film Faced Plywood Marine Plywood for Construction Formwork Hot Sale High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

| Type: | Plywoods | Place of Origin: | Shandong China (Mainland) | Brand Name: |

|

| Model Number: | (6) film faced plywood | Usage: | Indoor | Grade: | First-Class |

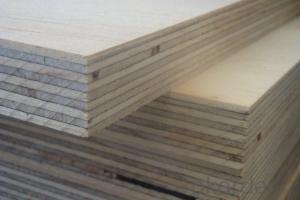

| Main Material: | Poplar | Formaldehyde Emission Standards: | E2 | Plywood Type: | 9-Ply Boards |

| thickness: | 9~25mm | core: | poplar/tropical hard wood | glue: | MR/melamine /wbp |

| certification: | ISO9001; CARB | plywood: | Construction grade black film faced plywood price | size 1: | 1220*2440mm |

| size2: | 1250*2500mm | usage1: | furniture | usage2: | construction |

| size3: | 915*2135mm |

Packaging & Delivery

| Packaging Detail: | plywood price export packing details : Standard export package or according your requirement. |

| Delivery Detail: | Within 15 days after receiving T/T or L/C in advanced |

Specifications

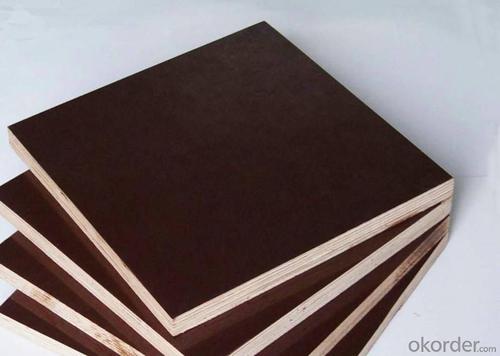

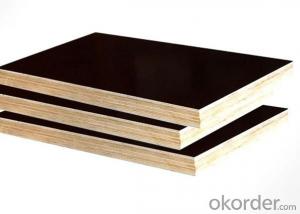

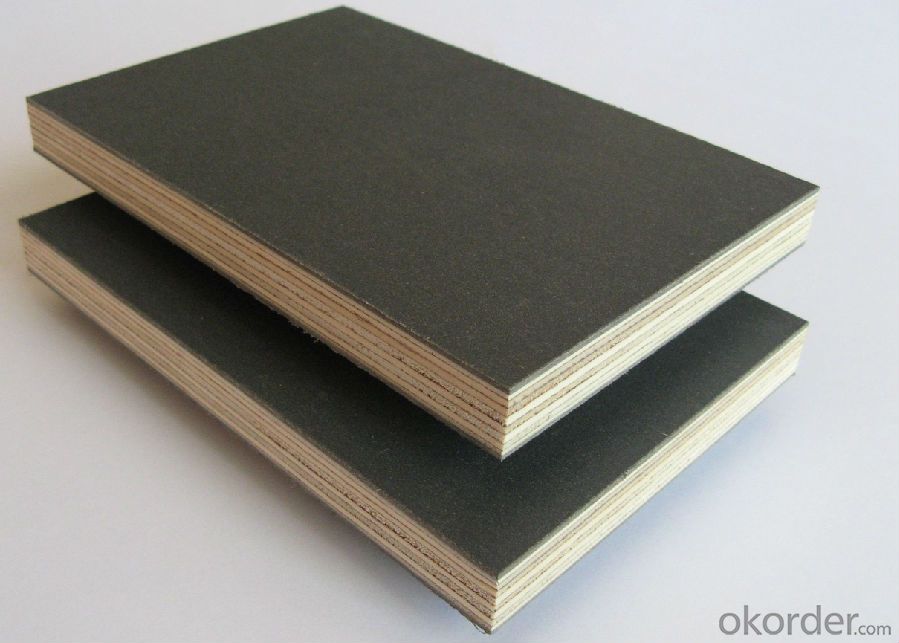

Film faced plywood black or brown film

size :1220*2440mm

thickness:9-25mm

glue :melamineMR ,wbp

core:poplar/combi/hardwood

Construction grade black film faced plywood price Introduction

------------------------------------------------------------------

Film faced plywood

size:1220*2440mm,915*2135mm or as customer requirements.

thickness:9mm-25mm

Core:poplar/hardwood/combi

density:500-550kg/m3

Glue:MR,MELAMINE,E1,E2,E0

Thickness tolerance:+/-0.2mm

-------------------------------------------------------------------

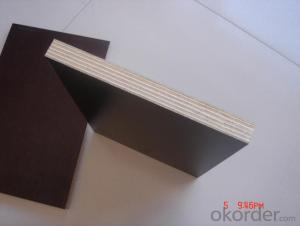

Specification(film faced plywood )

1)Specifications:1220mm×2440mm, 1250mm×2500mm, ,including other special sizes. |

2)Thickness: 9-25mm, which is allowed to be adjusted by the customers’ requests accordingly |

3)Core: poplar, birch, combi, hardwood |

4)Glue: WBP, MR, Melamine |

5)Surface:natual veneer ,melamine paper ,HPL |

6)Payment terms: T/T or LC at sight |

7)Price Terms: FOB, CNF, CIF |

8)Usages:can be widely used in construction, mould, etc.(poplar plywood) |

Package: Standard exporting packing Film :back film or brown film |

-------------------------------------------------------------------

Usage (film faced plywood )

Method of use:

When you cut the plywood,you must use metal saw with more than 100 teeth and the machine with orbital.

If you need the geometrical plywoo,you can use high speed protable saw.

After you cut the film facd plywodo or stilettoed,you must use the spcial lacquer to wipe out the cut to prevent the

film faced plywood sop water.

When you stilettoed,yu must put a wood under the film faced plywood to break.

When you used the film faced plyood,you must put glue to long th life of the plywood.

When you use the plywood,you must prevent the metal to break the plywodo and keep it's geometrical and full of the face!

Maintaing and sore

How to use and storage.After you use the film faced plywood,you must clean the face to good use!

When you use the film faced plywood for a long time,you must put some oil and stock in order with rain cloth.

When you trasport and stock the film faced plywood,you must prevent the sun and the rain to keep it's shape!

On the bulding site,the film faced plywood must stock on level up and dry place.You can't put them on the extrem temperature

FAQ:

Is CNBM a manufacturer?

Yes. CNBM is the biggest company in China for building materials. CNBM belongs to China Central government with more than 110,000 employees and owns more than 400 factories in China to make a varity of building materials products in China. Revenue of CNBM in 2014 is more than 50 billion US dollars.

How about the business of wood products in CNBM?

Wood products is a kind of traditional building material and it has been widely used in decoration place, furniture and construction areas. From the bigginning of CNBM business, CNBM setted up factories to produce the wood products like as plywood, MDF board, flooring, sawn timber and so on. Till today, CNBM invested a lot of money to forestry land and build a sustainable wood supplying industry from planting trees to wood final products.

What is the standard of wood products?

If no request from customers, we will make orders as per our own standard in factory, which is equal to or better than China national standard. Of course, we can make as customer's request. In fact, many orders made by us is per the standard of EN, USA,JIS etc.

- Q: How to use building plywood?

- Four types of plywood for the tide resistant plywood, used in the indoor normal, general purpose plywood with beech, linden wood, ash, birch, elm, poplar and so on.

- Q: Further processing of the plywood

- Anticorrosion plywood preserving treated plywood Plywood for use with potent or insecticide.

- Q: What types of plywood can be divided into?

- Class I (NQF) - weather resistant, resistant to boiling plywood Class II (Ns) - Water resistant plywood.

- Q: Multilayer plywood with what method is fixed

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other

- Q: The Preparation of plywood ingredients

- core core core sandwich panel or composite plywood center layer. Usually its thickness is greater than the other layers.

- Q: What is the use of plywood for construction?

- The number of veneer layers is odd, usually three to thirteen layers, common plywood, pallets, pallets

- Q: What is the difference between plywood glue E0E1?

- Melamine gel: moisture-proof, and has a certain resistance to boiling, weather resistance / can be used for outdoor or indoor, but can not often be water immersion.

- Q: Distinguish between multilayer boards and plywood

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other, usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides

- Q: One of the commonly used materials for furniture is a wood-based panel

- usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides.

- Q: What is the plywood made of wood?

- Production of plywood main tree species are: camphor, willow, poplar, eucalyptus, fir and so on

Send your message to us

Plywood 1 2 Inch Film Faced Plywood Marine Plywood for Construction Formwork Hot Sale High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords