Branded Green Colour Rubber Adhesive Masking Tape NZ

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 roll

- Supply Capability:

- 20000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General purpose of Green Colour Rubber Adhesive Masking Tape

1) good adhesive

2) good flexibility

3) No residual left

4) Different sizes are available

Feature of Green Colour Rubber Adhesive Masking Tape

general purpose masking tape, adhesive tape, paper tape.

1) good adhesion. 2) good flexibility.

-General purpose masking tape is made of crepe paper coated with natural rubber adhesives.

-It is designed for interior paint masking, light-duty packaging, holding, bundling, splicing and packaging.

-Practical for construction, building, home, office or industrial applications.

-Jumbo roll, log roll and cut roll are available.

-The width of jumbo roll is from 980mm - 1250mm

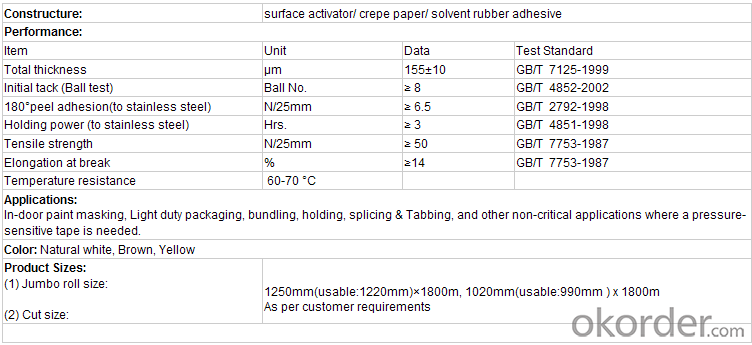

Specifications

Advantages of Green Colour Rubber Adhesive Masking Tape:

Different temperature resistance with good adhesion

High tensile strength, good resistance of damage, no residue, eco-friendly

Accept custom design

SGS, ISO, BV, CTI certificates approved

Professional teamwork for orders

No.267 on the 2014 Fortune Global 500

Professional manufacturer with 31 years experiences of adhesive tapes

Special size, color can be made according to customer's requirement.

Our Services

Your inquiry related to our product & price will be replied within 24 hours.

Well-trained & experienced staff can answer all your inquiries in English or other language

Your business relationship wit us will be confidential to any third party

Good after-sale service offered please free feel to contact us for more information

FAQ

Q 1: Do you have any MOQ of Wonder Masking Tape?

A: Yes, according to the size you need.

Q 2: What is the delivery time?

A: Sample time 7 days, 30 days for the mass production.

Q 3: Can we put our logo on the products?

A: Yes, welcome.

Q 4: How should I pay for you if I place order to you?

A: Usually, 30% T/T deposit in advance, 70% balance against the copy of B/L.

- Q: Can packaging tape be used for repairing torn paper?

- No, packaging tape is not suitable for repairing torn paper. Packaging tape is designed for securing and sealing boxes and packages, and its adhesive is very strong and may cause further damage to the torn paper. Instead, it is recommended to use a specialized paper repair tape or adhesive, which is specifically designed for repairing torn paper. These tapes are typically acid-free and have a gentle adhesive that is safe for use on delicate papers. Using the right tools and materials will ensure a proper and long-lasting repair without causing further damage to the torn paper.

- Q: How do I prevent packaging tape from curling up?

- To prevent packaging tape from curling up, there are a few things you can try: 1. Use a tape dispenser: Using a tape dispenser helps keep the tape straight and prevents it from curling. It also makes it easier to cut the tape to the desired length. 2. Apply tape evenly: When applying the tape, make sure to pull it tightly and apply it evenly across the surface. Avoid any wrinkles or bubbles as they can cause the tape to curl up. 3. Clean the surface: Ensure that the surface where you are applying the tape is clean and free from any dust, dirt, or moisture. These factors can interfere with the adhesive properties of the tape, causing it to curl. 4. Store tape properly: Proper storage of packaging tape is essential to prevent it from curling. Keep it in a cool, dry place away from direct sunlight. Extreme temperature changes can affect the tape's adhesive properties and lead to curling. 5. Choose good quality tape: Invest in high-quality packaging tape that is designed for long-term adhesion. Cheaper tapes often have lower quality adhesives that are prone to curling. 6. Use a heat source: If you are experiencing curling issues with the tape, you can try using a heat source like a hairdryer on a low setting. Gently heat the tape while applying it to help activate the adhesive and reduce curling. By following these tips, you should be able to prevent packaging tape from curling up and ensure a secure and professional-looking packaging.

- Q: How does packaging tape perform on fabric or textile surfaces?

- Packaging tape typically does not perform well on fabric or textile surfaces. While it may adhere temporarily, it does not provide a strong bond on these materials and is not designed to withstand the flexibility and movement of fabrics. Additionally, the adhesive on packaging tape may leave residue on the fabric or even damage it when removed. Therefore, it is not recommended to use packaging tape on fabric or textile surfaces. Instead, it is advisable to use specialized fabric tapes or sewing techniques for any applications involving fabrics.

- Q: What are the common sizes of packaging tape?

- The common sizes of packaging tape typically range from 1.88 inches to 3 inches in width, while the length can vary depending on the brand and type of tape.

- Q: Does packaging tape leave residue?

- Indeed, surfaces can be affected by residue when packaging tape is used. This occurrence arises from the fact that the majority of packaging tapes possess adhesive properties, meant to firmly adhere to surfaces. Consequently, when the tape is detached, it has the potential to leave a sticky residue behind which may prove arduous to eliminate. Moreover, this residue is prone to accumulating dust and dirt, thereby intensifying the difficulty of the cleaning process. Nonetheless, there are certain packaging tapes available that are explicitly engineered to minimize or entirely eliminate residue upon removal. To guarantee the absence of any unwanted residue, it is always prudent to conduct a preliminary test on a small area of delicate or valuable surfaces before employing packaging tape.

- Q: Does packaging tape come in different allergen-free options?

- Yes, packaging tape is available in various allergen-free options. Many manufacturers offer packaging tapes that are specifically designed to be hypoallergenic and suitable for individuals with allergies or sensitivities. These tapes are typically free from common allergens such as latex, gluten, and certain chemical irritants. It is important to check the product description or contact the manufacturer to ensure that the packaging tape meets your specific allergen-free requirements.

- Q: How do I apply packaging tape evenly?

- To apply packaging tape evenly, follow these steps: 1. Start by ensuring that the surface you are taping is clean and free of any dust, dirt, or moisture. This will help the tape adhere properly. 2. Measure the length of tape you need and cut it accordingly. It is better to have a slightly longer piece of tape than a shorter one. 3. Hold one end of the tape firmly against the surface you are taping and apply it at a slight angle, using gentle pressure. This will help prevent air bubbles and ensure a smooth application. 4. As you continue applying the tape, make sure to keep it taut and straight. Avoid stretching or pulling the tape too tightly, as this can cause it to lose its adhesive properties. 5. Use your fingers or a tape dispenser to press down on the tape firmly, smoothing it out as you go. This will help ensure that it adheres properly and evenly to the surface. 6. If you encounter any wrinkles or bubbles while applying the tape, gently lift the tape and reapply it, smoothing it out as you go. 7. Repeat the process until you have covered the desired area with the tape, making sure to overlap the edges slightly for a secure seal. By following these steps, you should be able to apply packaging tape evenly, creating a neat and secure seal for your packages.

- Q: Can packaging tape be used for sealing packages with sharp edges or corners?

- Yes, packaging tape can be used for sealing packages with sharp edges or corners. Its strong adhesive properties and durability make it suitable for securing boxes and ensuring that the package remains intact, even when subjected to sharp edges or corners.

- Q: What are the considerations for using packaging tape on glossy surfaces?

- When it comes to using packaging tape on glossy surfaces, it's important to keep a few key things in mind. First and foremost, the smoothness and slickness of the glossy surface can affect how well the tape sticks. The glossy finish creates a barrier that can make it difficult for the tape to adhere securely. That's why it's crucial to make sure the surface is clean and free from any dirt, oils, or residue that could prevent the tape from sticking properly. Choosing the right type of packaging tape is also important. Opting for a tape specifically designed for glossy surfaces, like high tack or acrylic adhesive tapes, can provide better adhesion and last longer. These tapes are specially formulated to stick well to smooth surfaces and create stronger bonds compared to regular packaging tape. It's also a good idea to test the tape on a small, inconspicuous area of the glossy surface before applying it everywhere. This will let you see how well the tape sticks and ensure that it doesn't leave any residue or damage the glossy finish when you remove it. Temperature and environmental conditions should also be taken into consideration. Extreme heat or cold can affect how well the tape performs on glossy surfaces. For example, high temperatures can cause the adhesive to soften, leading to the tape failing, while cold temperatures can make the tape more brittle and prone to peeling. Lastly, it's crucial to handle the glossy surface with care to avoid leaving fingerprints, smudges, or scratches that could detract from its appearance. Wearing gloves or using protective films can help prevent these issues. By keeping these factors in mind, you can enhance the effectiveness and reliability of packaging tape on glossy surfaces, ensuring that your packages are securely sealed without compromising the glossy finish's aesthetic appeal.

- Q: What are the benefits of using easy-release packaging tape?

- The benefits of using easy-release packaging tape include faster and more efficient packaging, reduced frustration and time wasted on struggling with traditional tape, easy removal without damaging the contents or leaving residue, and improved overall packaging experience.

Send your message to us

Branded Green Colour Rubber Adhesive Masking Tape NZ

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 roll

- Supply Capability:

- 20000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords