Box Facial Tissue Packaging Machine Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Box Facial Tissue Packaging Machine Made in China:

This machine is mainly used for making jumbo tissue into daily using small tissue.

2. Main Features of Box Facial Tissue Packaging Machine Made in China:

Raw material:waste paper pulp,wood plup,bamboo pulp

Output:newspaper,writing paper,printing paper, transfer printing paper (A3,A4paper) , Output: Paper weight: 40-120 g/m

Net paper width: 1600mm

Capacity: 10ton per day

Width of cylinder mould: 1950 mm

Rail gauge: 2400 mm

Drive way: AC frequency conversion speed, section drive

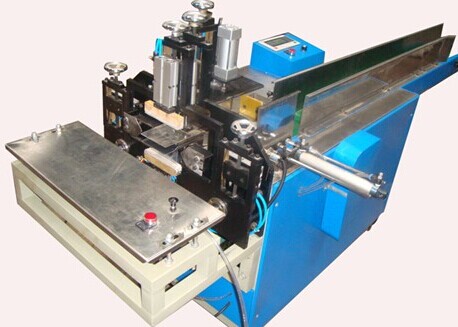

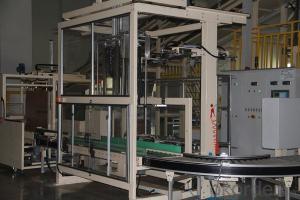

3.Box Facial Tissue Packaging Machine Made in China Images:

4.Box Facial Tissue Packaging Machine Made in China Specification:

Cylinder section: Φ1500mm×1950mm stainless steel cylinder mould 2 sets, Φ450mm×1950mm couch roll 2 set, φ400×1950mm reverse roll 1set, coated by rubber,rubber shore hardness 38℃±2.pneumatic loading device.

Press section: Φ500mm×1950mm marble roll 1 set, Φ450mm×1950mm rubber roll 1 set, coated by rubber,rubber shore hardness 90℃±2.

Dryer section:Φ2500mm×1950mm alloy dryer can 1 set, Φ1500mm×1950mm alloy dryer can 3 set,Φ500mm×1950mm touch roll 1 set,coated by rubber,rubber shore hardness 90℃±2.

Drive way :AC frequency conversion speed, section drive

Pneumatic compression device.

5.FAQ of Box Facial Tissue Packaging Machine Made in China:

We have organized several common questions for our clients, may help you sincerely:

1)How about your company?

A world class manufacturer & supplier can supply you good products for all worlds customer with high quality and competitive price

2)How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3)How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: A printing factory to do the processing, mainly in the brochure and paper products packaging box mainly should buy what equipment and printing machine for what, how much money?

- The post worker can be sent out to someone else. Sufficient funds, more, you can buy the printing machine, CTP plate machine, cutting knife, folding machine, bookbinding machine, laminating machine, die cutting machine and so on. At the beginning, can buy mobile phone ah.

- Q: How much do you need for the mechanical equipment for making paper boxes?

- 3, the paper glued to the tile covering: paper, cardboard become. The use of machine: 1) glue machine, simple equipment, manual operation, thousands of pieces of 2) semi automatic cladding machine, automatic tile paper, manual feed paper, about one hundred thousand, generally less than 100 thousand, 3 automatic cladding machine, about two hundred thousand),4, die cutting: the cardboard pressed into the target shape, and then used to shape. Machine: 1) flat die cutting machine (tiger beak), different models, prices ranging from less than fifty thousand of the general model. 2) round pressure garden die-cutting machine, fifty thousand or sixty thousand bar, 3) semi-automatic flat die cutting machine, about two hundred thousand, a lot of difference, but fast, safe.5, molding: the carton or nail box, or sticky box, finished processing. 1) nail box machine, thousands of blocks, 2) carton machine. Different models, different prices, generally tens of thousands of blocks, more than 10000 of the ordinary. 3) manual adhesive box, 4) automatic paste box machine,

- Q: Does the toilet paper factory need to install dust removal equipment?

- You can consult the local environmental protection department, you can also consult

- Q: How much does it cost to buy a toilet paper processing plant?

- This, looking for a small project to do good, also can choose another way, you can learn a lot of a lot of experience, I had seen a product at a friend's house, is that with a few simple tools in the wall painting, painting is also very simple, the painting is very lifelike vivid

- Q: 1880, the production of toilet paper, the machine can be processed what paper?

- Automatic paper, automatic bar, pumping shaft flattening, automatic trimming, glue and other functions in one, relatively suitable for small and medium-sized toilet paper processing factory.

- Q: I want to do the carton machinery sheet metal processing plant. What equipment do I need? How much will it cost in general? I heard it is laser cutting, CNC bending and so on! Ask the master for advice

- Look at the kind of processing you're going to use, if it's the traditional process,

- Q: How about profit from paper processing? I didn't touch the paper industry. How much do you invest in a small factory like this? How many machines do you need? What kind?

- The price is not expensive, rewinder 17W / Taiwan, paper cutting machine 6K / Taiwan, printing machine 12W / Taiwan

- Q: Intends to open a living paper processing plant, rewinding machine power consumption is three-phase electricity, as well as paper cutting machine, packaging machine, mainly for pumping paper and roll paper, please ask what equipment to buy?

- Three phase power is required. The paper machine needs a folding machine and a packing machine

- Q: I want a straw machine, a wheat packing machine, a paper bag for processing power plants and paper mills

- Subsidies, manufacturers, models, they know more about the local straw

- Q: I want to do A4 paper processing! What machine do I need to do? We here have a lot of large wholesale mills it large rolls of paper how processed into finished A4

- When you measure up, add the automatic equipment, mainly the fields and the purchase paper. You must know the paper, otherwise...... Dead meat.

Send your message to us

Box Facial Tissue Packaging Machine Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords