Paper Slitter Rewinder Machine Suppplied in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Paper Slitter Rewinder Machine Supplied in China:

This machine is mainly used for making jumbo tissue into daily using small tissue.

2. Main Features of Paper Slitter Rewinder Machine Supplied in China:

This machine is using computer control system, automatically running, simply operating.

This machine is frequency control of motor speed, pneumatic control..

Seting perforating, rolling, automatic gluing, cutting, sealing in one machine, ensure rolling steady.

Automatic deflashing, making the paper no loss when the toll paper moving into the paper cutter, improving production efficiency and production grade.

It can produce hollow -core and solid-core toll toilet paper.

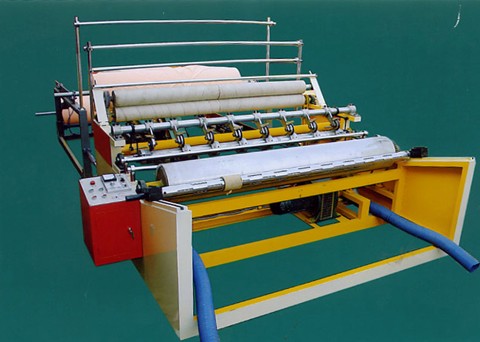

3.Paper Slitter Rewinder Machine Supplied in China Images:

4.Paper Slitter Rewinder Machine Supplied in China Specification:

Cylinder section: Φ1500mm×1950mm stainless steel cylinder mould 2 sets, Φ450mm×1950mm couch roll 2 set, φ400×1950mm reverse roll 1set, coated by rubber,rubber shore hardness 38℃±2.pneumatic loading device.

Press section: Φ500mm×1950mm marble roll 1 set, Φ450mm×1950mm rubber roll 1 set, coated by rubber,rubber shore hardness 90℃±2.

Dryer section:Φ2500mm×1950mm alloy dryer can 1 set, Φ1500mm×1950mm alloy dryer can 3 set,Φ500mm×1950mm touch roll 1 set,coated by rubber,rubber shore hardness 90℃±2.

Drive way :AC frequency conversion speed, section drive

Pneumatic compression device.

5.FAQ of Paper Slitter Rewinder Machine Supplied in China:

We have organized several common questions for our clients, may help you sincerely:

1)How about your company?

A world class manufacturer & supplier can supply you good products for all worlds customer with high quality and competitive price

2)How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3)How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: I would like to open a paper napkin and toilet paper processing plant. What equipment do I need? What are the recommended brands?

- General training operations technology, production line, then the need for manual not many, generally four or five people or two or three people can operate

- Q: Machine for processing web paper

- It won't sink together because of the different fields in it! If you can, you send me the form to see if it can be optimized

- Q: Do you sell machines for processing paper napkins?

- If you want to find a cheaper one, go to the hotel and ask who is serving it and should be able to find it.

- Q: How much is wallet, paper napkin processing equipment and packing machine?

- Napkins have colored napkins, embossed paper napkins, see what kind of effect you want to paper napkins

- Q: 1880 how much is a machine for processing toilet paper?

- But the rewinder can add different functions, such as embossing or embossing, and consult the manufacturer in detail.

- Q: What kind of equipment do you need for a small towel factory?

- A paper towel machine, a wrapping machine, a paper towel machine, see what you plan to do, different products, machines are different, are paper towels

- Q: How big is the paper machine? I'd like to open a new paper processing factory. Which one has better quality?

- Use 1880 of this more moderate model. The equipment is still looking for larger factories, and more comparisons!!

- Q: How much is a set of 1880 toilet paper processing equipment?

- Function with embossed edge, with paper tube, with embossing, eight hours a day can produce two tons or so.Thank you for taking the adoption of pure hand

- Q: How much does a full set of toilet paper processing machines cost?

- Band saw, paper cutting machine and sealing machine, if you start from waste paper, you need to buy paper machine, generally need to invest hundreds of thousands of

- Q: I want a straw machine, a wheat packing machine, a paper bag for processing power plants and paper mills

- Subsidies, manufacturers, models, they know more about the local straw

Send your message to us

Paper Slitter Rewinder Machine Suppplied in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches