Borosilicate 3.3 Heat-resistant Glass Household Electrical Appliance Glass Panel Glass Tray BG33

- Loading Port:

- NANJING

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Borosilicate Float Glass3.3(BG33)

Our 3.3 borosilicate glass is extremely versatile too – you can use it for almost any purpose imaginable; such as microscope slides and petri dishes; kitchenware items like oven-proof baking dishes; art projects like stained-glass windows.

The possibilities are endless! Its lightweight yet strong construction allows for easy transport between workspaces so you can take your creations wherever they need to go.

And thanks to its crystal clear transparency, light passes through beautifully with no distortion whatsoever - making sure whatever design you come up with looks perfect every time!

Borosilicate Float Glass3.3 Introduction

This revolutionary glass is made of borosilicate, a special material that combines strength and durability with an extraordinarily high heat resistance.

Whether it's functional or decorative, this magnificent material will make any project look great while helping protect against extreme temperatures up to 500°C (932°F). And because of its excellent thermal shock properties, it won't cloud over time from frequent temperature fluctuations either!

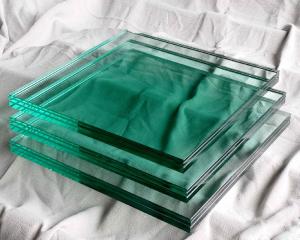

Borosilicate float glass 3.3 is a special glass material with low expansion rate, high emperature resistance, high strength, high hardness, high light transmittance and high chemical stability.

Because of its excellent performance, it is widely used in household appliances, environmental engineering, medical technology, safety protection and other fields, especially in the field of household appliances, borosilicate float glass 3.3 is widely used as the panel and inner tray of ovens and microwave ovens.

In addition, because the hardness of borosilicate float glass 3.3 is 8-10 times that of ordinary glass, it is also used as bulletproof glass by many customers.

Product Features

Great heat resistance performance

Stable chemical property

High light transmission

Various thicknesses for you to choose

Wide optical application

Application field

Borosilicate 3.3 serves as a material of true function and wide applications:

1). Household electrical appliance (panel for oven and fireplace, microwave tray etc.);

2). Environmental engineering and chemical engineering (lining layer of repellence, autoclave of chemical reaction and safety spectacles);

3). Lighting (spotlight and protective glass for jumbo power of floodlight);

4). Power regeneration by solar energy (solar cell base plate);

5). Fine instruments (optical filter);

6). Semi-conductor technology (LCD disc, display glass);

7). Medical technique and bio-engineering;

8). Safety protection (bullet proof glass)

Advantages

High borosilicate 3.3 glass is high-temperature resistant glass, heat-resistant glass and temperature difference resistant glass.

The linear expansion coefficient is 3.3 ± 0.1 × 10-6 / K, is a glass with sodium oxide (Na2O), boron oxide (b2o2) and silicon dioxide (SiO2) as the basic components.

The content of boron and silicon in the glass composition is relatively high, namely, boron: 12.5 ~ 13.5%, silicon: 78 ~ 80%.

The expansion coefficient will affect the stability of glass.

The expansion coefficient of borosilicate 3.3 heat-resistant glass is 0.4 times that of ordinary glass.

Therefore, at high temperature, borosilicate 3.3 heat-resistant glass still maintains excellent stability and will not crack or break.

The long-term working temperature of borosilicate 3.3 heat-resistant glass can reach 450 ℃, so it is often used as the microwave oven panel.

At high temperature, borosilicate 3.3 heat-resistant glass can not only work normally, but also maintain high permeability, which is convenient for users to observe the internal food state.

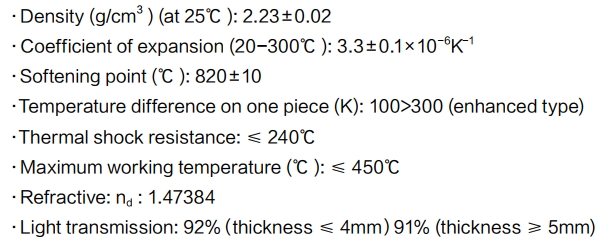

Technical Data:

Thickness Range: 2mm-20mm

Size: 1150*850 / 1700*1150 /1830*2440 /1950*2440 Max.3660*2440mm,

other specifications can be produced according to customer requirements.

Color: ultra-clear, transmittance 92%

Thermal properties

Optical data

Optical index of refraction:1.48

Mechanical properties

Density ρ (25°C) :2.23ɡ/cm3

Young's Modulus E (according to DIN 13316):64 kN/mm2

Poisson's Ratio μ (according to DIN 13316):0.2

Bending Strength σ (according to DIN 522922 T 1) :>25MPa

Packaging Photos of Borosilicate Glass 3.3

Package and transport

Minimum order quantity: 2 tons, capacity: 50 tons/day, packing method: wooden case.

Processing

Pre-cut formats, edge processing, tempering,drilling, coating, etc

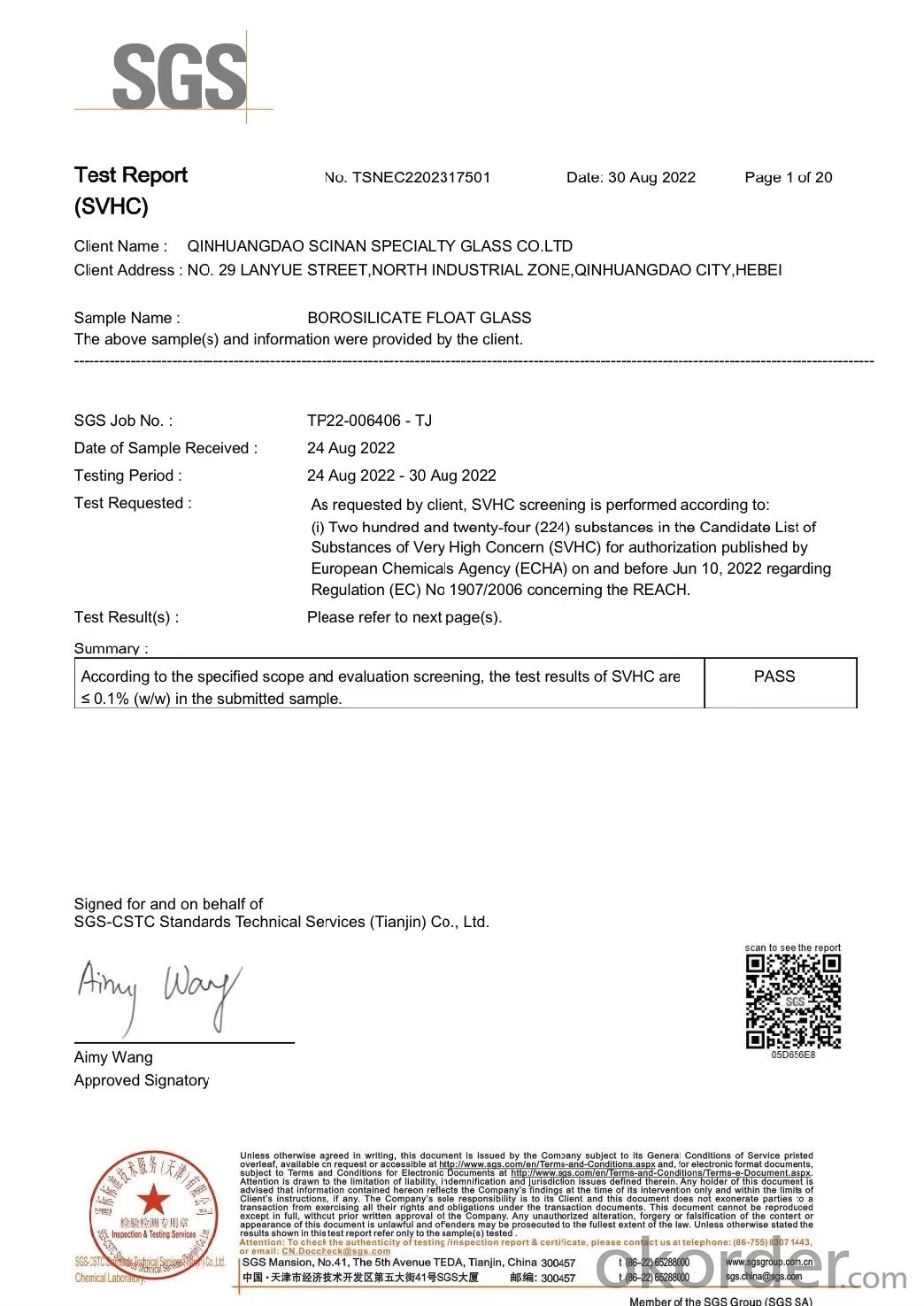

Our certification

At present, the company has passed the SGS certification the ISO9001 management system certification and so on.

The company has 21 national patents and obtained the certification of high-tech enterprises.

Our Advantage

It is the first high-tech enterprise in China to produce borosilicate flat glass products by full electrofusion technology.

At present, the domestic market share industry ranks first.

The core technology of the production line is self-developed, the key equipment is the most advanced industrial products, the company set borosilicate flat glass production, processing, sales and service as one, sales network has been spread throughout the country and many countries and regions of the world.

- Q: I have been laid off my job of 26 years doing exactly this. I would like to look into teaching at a community college passing my skills onto others. Any advice?How much do you think I could expect to get paid?Thanks in advance!

- Start by going to yahoo questions and posing a question along this lines: how do I go about getting a job teaching others to design and build leaded glass windows? Then wait for brilliant ideas to make you into the next Bill Gates (or Windows as the case may be).

- Q: what is an ideal roof for a steel framed building with glass cladding?

- each floor could be of concrete slab, or concrete decking, the last roof could be of corregated sheets with translucent panels for natural lighting , glass cladding is an architectural element and not structural element

- Q: Any1 know wat that big glass building is next to City Hall in Cork???

- i think its the new building for doing tax,bin charges etc. my friend thinks its a libary and i heard some1 else say it was part of the fire station so who knows....go in there someday thats the quickest way to find out!!!!!!!

- Q: Laminated glass and low-emissive glass which earlier?

- It seems to be laminated glass (do not know right ..)

- Q: effects of rain, heat, pressure, snow

- If you are planning to start on your woodworking project, this isn't something you should use, it's something that you would be insane not to.

- Q: China's largest glass deep processing enterprises which

- China 's largest glass deep - processing enterprises Taiwan Glass Group, China' s largest glass of the original film, architectural glass company.

- Q: There is a 100 story high building. We have 2 identical glasses. We would like to know the highest floor from which it is possible to drop a glass and not have it broken on the ground. What is the least number of experimental drops we need in order to determine the answer? (and how so?)I know it is less than 19.

- 7 drops should be needed to be sure. #1 drop from the 50th floor breaks, go to 25. Doesn't break, goto 75 # 2 breaks from 25, goto 12. Doesn't break from 25, goto 37 # 2 breaks from 75, goto 62. Doesn't break from 75, goto 87 # 3 breaks from 12, goto 6. Doesn't break from 12, goto 18 # 3 breaks from 37, goto 31. Doesn't break from 37, goto 43. # 3 breaks from 62, goto 68. Doesn't break from 62, goto 56. # 3 breaks from 87, goto 81. Doesn't break from 87, goto 93. As you can see, each drop allows you to cut the min-max distance by 1/2. Within 6 or 7 tries you should have a valid answer. Ok, with your new I info I have a new answer. :) Least number of drops = 2 (floors 10 and 1 (both break) Most number of tests = 18. (floor 99) Drop from floors 12 1+11 24 2+11 36 3+11 48 4+11 60 5+11 70 6+9 80 7+9 90 8+9 100 9+9

- Q: How to distinguish between glass and glass?

- Jun Ding glass to tell you a more convenient way to identify, that is, gently hit them, the glass will be issued a crisp metal color (because the glass contains metal oxide), and glass is not; there is through the color recognition, only Glass a variety of colors can be integrated with each other, any other glass after the fusion of a variety of colors will burst later.

- Q: Does anyone know of an automobile from the 1930's that had 2 large built in glass flower vases in the backseat on either side?

- those types of cars in that year would be custom built/the chassis and cab from maybe cadillac and the body from custom builder/thomas edisons daughter had one and it is really beautiful/the "trunk" is a real trunk attached to a rear bumper/so no production car is available

Send your message to us

Borosilicate 3.3 Heat-resistant Glass Household Electrical Appliance Glass Panel Glass Tray BG33

- Loading Port:

- NANJING

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Qinhuangdao Scinan Special Glass Co., Ltd.

Qinhuangdao Scinan Special Glass Co., Ltd.