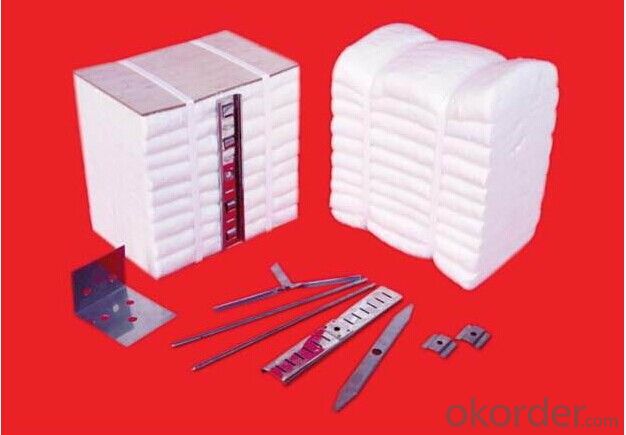

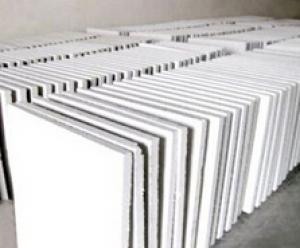

Ceramic Fiber Module with Anchor System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Ceramic Fiber Modules with Anchor System

1.professional factory

2.ceramic fiber modules

3.SS310 refractory anchor

4MSDS

Petro-industry: Heater,Reformer ,Cracking Furnace

All other industrial kilns such as heat-tre, atment furnace,ceramic kiln and kiln car

Lowbulk density

Low thermal conductivity

Resistance to heat-shock

Resistance to airspeed eroding

High mechanical strength

High safety within anchor Easy installation

Descriptions | COM | STD | HP | HA | ZA | ||

Classification temperature (°C) | 1260 | 1260 | 1300 | 1400 | 1430 | ||

Operating temperature(°C) | ‹1000 | 1000 | 1150 | 1200 | 1350 | ||

Density(kg/m3) | 190-240 | 190-240 | 190-240 | 190-240 | 190-240 | ||

The chemistry constitute (%) | AL2O3 | 44-45 | 45 | 47-49 | 52-55 | 39-40 | |

AL2O3+SiO2 | 96 | 97 | 99 | 99 | - | ||

AL2O3+SiO2+ZrO2 | - | - | - | - | 99 | ||

ZrO2 | - | - | - | - | 15-17 | ||

Fe2O3 | 1.2 | 1 | 0.2 | 0.2 | 0.2 | ||

Na2o+K2O | 0.5 | 0.2 | 0.2 | 0.2 | 0.2 | ||

Dimensions (mm) | 610×300×100-200(without Anchor);300×300×175-250(With Anchor or without Anchor);Other specifications according to the customer request | ||||||

- Q: Can ceramic fibers be spun? Hope experts answer, if you are the one!

- Ceramic fiber can be spun, but certain auxiliary materials must be added. The ceramic fiber is soft, and the resistance and non - fiber of the ceramic fiber must be guaranteed.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber surface roughness, accurate size, good toughness, can be arbitrarily cut, good insulation effect; ceramic fiber board can be distinguished according to the temperature, heat is widely used in the back lining of industrial furnace and kiln temperature, kiln is an important guarantee for energy saving, high yield and quality factors of A.

- Q: Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

- Tile blanket thickness 30mm, (2 layers of 20mm compression), hot surface layer, ceramic fiber module thickness of 300mm, total thickness of 330mm. The ceramic fiber module adopts a standard ceramic fiber module with a temperature range of 1260.Considering that the flame sprayed by the nozzle will rebound on the outer wall of the zinc pot and form a smoke wash between the furnace wall and the zinc pot wall, the wind speed is about 18m/s to 23m/s, and there is a certain corrosion. Ceramic fiber module surface brushing two times curing agent, that is resistant to corrosion, but also can resist high wind speed.

- Q: How to install refractory fiber?

- Dry plate is used spray adhesive, mechanical compression molding, low density, has good flexibility and flexibility, generally used for insulation seal. Wet washing mold, vacuum forming board of high density, good hardness, can be processed mechanically, generally used for fire-resistant insulation.

- Q: What about the composite reflecting insulation board and ceramic fiber?

- The maximum temperature of ceramic fiber heat insulation material can be up to 1400 degrees. Although the highest use temperature of ceramic fiber is higher than that of Tianjin solid composite reflecting insulation board, the heat insulation effect is far worse.

- Q: What is the refractory temperature of the ceramic fiber cloth?

- Non-toxic, harmless, no adverse effects on the environment; the scope of application of ceramic fiber cloth: all kinds of high temperature furnace, thermal insulation pipes and containers; door, valve, flange sealing, fire door, fire shutter door curtain, high temperature sensitive materials; engine and instrument cable insulation, fireproof coating material, fireproof material; thermal insulation cover with cloth, high temperature expansion joint filler, flue lining; high temperature resistant safety products, fire service, high temperature filtration, sound and other fields instead of asbestos

Send your message to us

Ceramic Fiber Module with Anchor System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords