High Alumina Blast Hearth Brick Corundum Composite Brick for Blast Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM Group is listed No.187 in on Fortune Global 500, 2020.

Refractory is one of the main products of the group. At the same time, under the globalization strategy, CNBM International is the exporter, logistic and local service supplier.

13 Refractory plants locate in 9 different cities

15 professor level senior engineers,239 engineers,5 senior experts committed Iron & Steel industry

Annual production capacity is over 400,000 tons.

Product Name: Blast Hearth Brick Corundum Composite Brick for Blast Furnace

Features:

Low creep

Good thermal shock resistance

Good chemical corrosion resistance

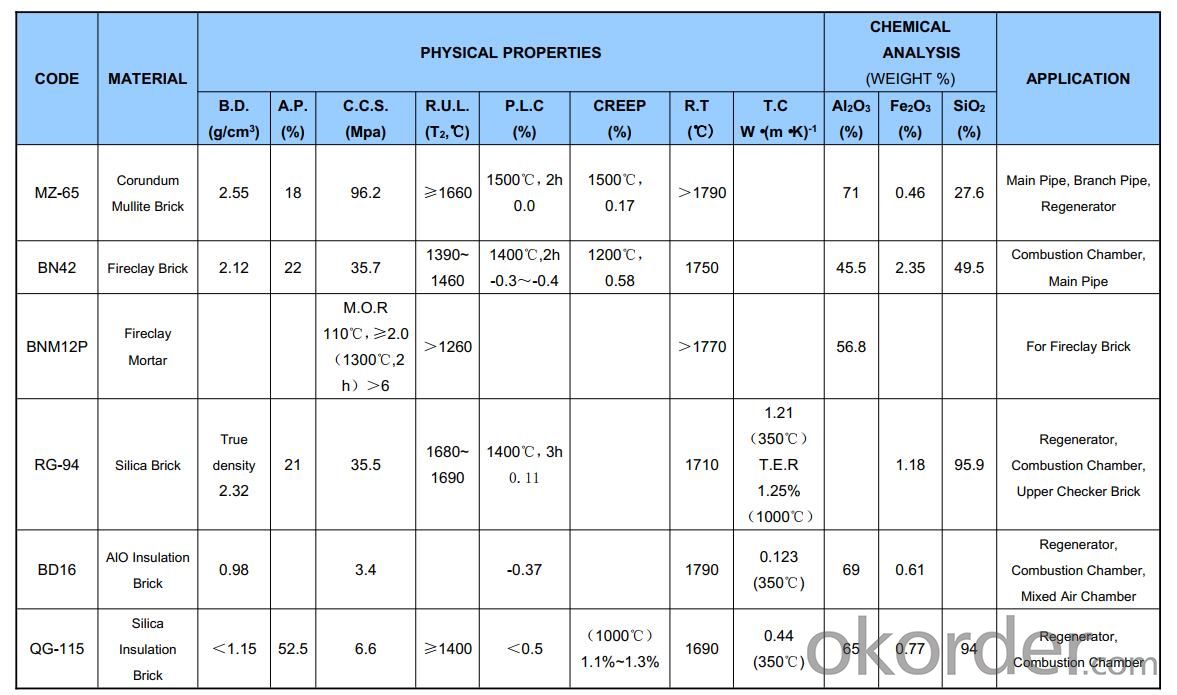

Technical Data Sheet

Product Photos of Blast Hearth Brick Corundum Composite Brick for Blast Furnace

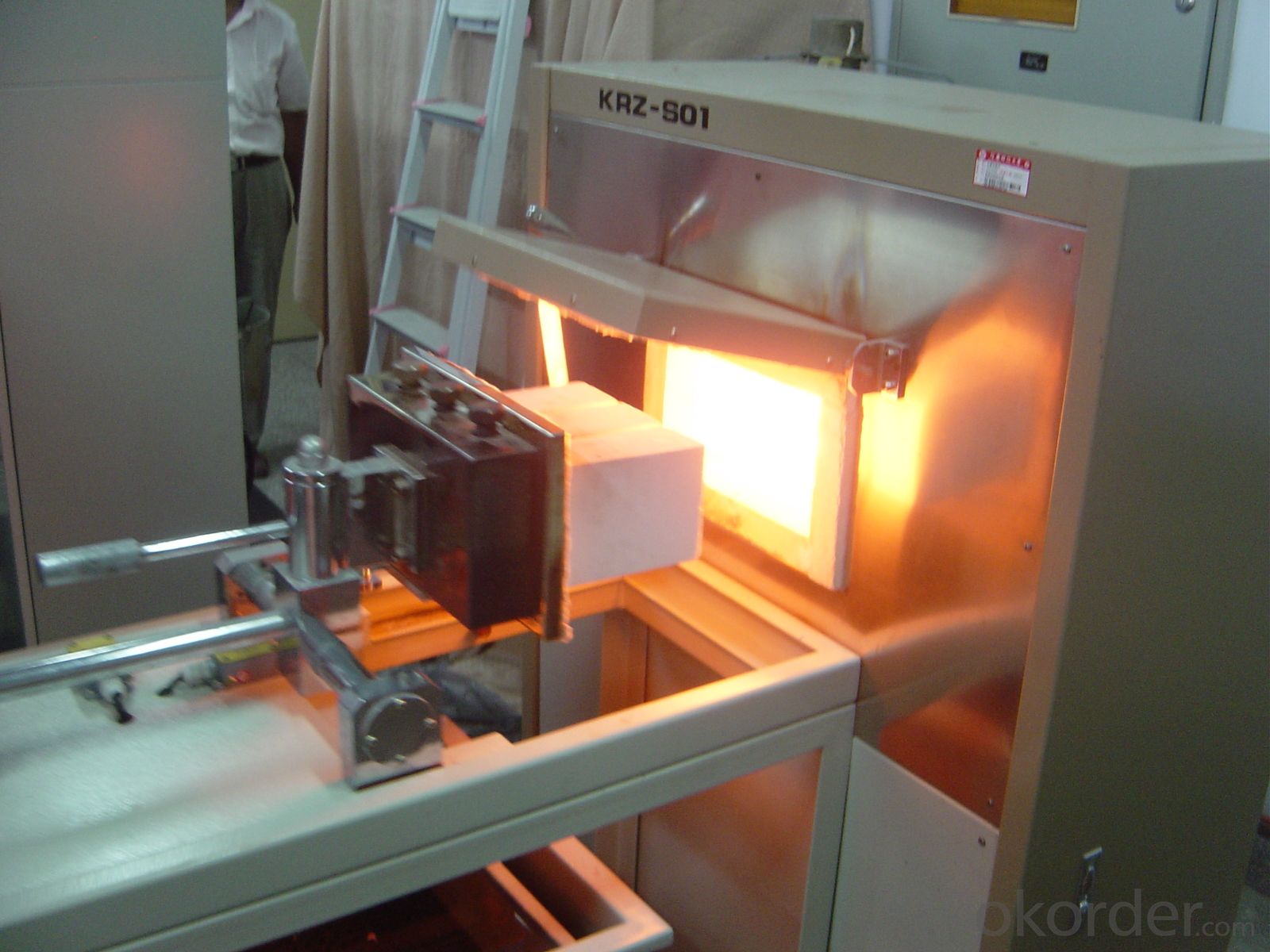

Our workshop

- Q: What is fireproof concrete?

- A series of concrete with fire resistance and heat resistance is made of Portland cement series as cementing material and heat-resistant material as aggregate. Silicate fireproof heat-resistant concrete with Portland slag cement, Portland cement and water glass as cementing material, broken clay brick, clay, cement clinker, broken high alumina brick as aggregate.

- Q: In 2016, a few of the traditional refractory materials will be able to survive

- The other is in large enterprises and individual has the unique advantage of the small enterprises, with independent technology system, production equipment advanced, there are certain funds set up to deal with risk, timely reform, such enterprises compared to a few years ago the productivity and sales or have declined, but overall is still in the stage of production increased steadily.

- Q: What are the main components of high alumina bricks?

- High alumina brick materials according to the main mineral phase can be divided into: aluminum silicate minerals, such as sillimanite, kyanite, andalusite, and synthetic mullite.

- Q: What refractory material does cupola lining use?

- It's made of high quality refractory material: 1770 ~ 2000 centigrade.

- Q: What is the standard size of high alumina brick?

- Standard brick: 230 x 115 x 65; four points: 230 x 115 x 40; three points: 230 x 115 x 30; 150 x 120: Brick gable. Light weight brick 1 to 1.7 kilograms; heavy clay superscript brick weighs 3.75 kilograms; light 30 plates 0.79 kilograms; light 40 plates, 1.05 kilograms.

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- Quality requirements for aluminium bricks of different grade. 2, high aluminum powder and high alumina aggregate and other materials of reasonable proportion, to reach the production requirements.

- Q: What materials are used for roof insulation?

- There are two kinds: one is a kind of cotton insulation board, such as rock wool board, aluminum silicate cotton board, but this is not environmental protection, harmful to life, foam board (this fire safety factor minimum), these relatively cheap.

- Q: What are the specifications for bricks?

- Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels. Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks.

- Q: How does the physicochemical index change when the high alumina brick is used at high temperature?

- When the high alumina brick is used at high temperature, the physical and chemical indexes and other constants will not change if the temperature is in the physical and chemical indexes and the softening temperature of the load.

- Q: The difference between clay bricks and clay bricks

- Clay brick is a small building with artificial bulk. Also called sintered brick. Solid clay brick is one of the oldest building materials in the world. It is a building material that is loved by the people.

Send your message to us

High Alumina Blast Hearth Brick Corundum Composite Brick for Blast Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords