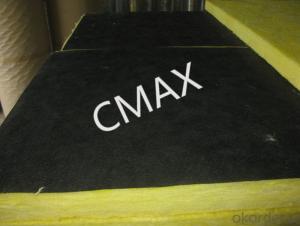

Glass Wool Black Tissue Faced Blanket

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Description:

Insulation Glass Wool Pipe

In the field of insulation materials, weare mainly specializing in Glass wool products, including blankets, boards andpipes. The advantage of this material is numerous: noncombustible, nontoxic,and resistant to corrosion. It has low weight, low thermal conductivity, stablechemical property, low moisture rate and good hydrophobicity. These productshave been widely used in heat preservation, thermal insulation and soundabsorption in construction, chemical industry, electronic industry, electricpower, metallurgy, energy industry, and communication. High density panelslaminated with facing can be used for Air-conditioning duct system.

TECHNICAL DATA

Item | Unit | Index |

Density | Kg/m3 | 10-100 |

Average Fiber Diameter | μm | 5-7 |

Water Content | % | ≤1 |

Grade of Combustibility | Non-Combustible Grade A | |

Reshrinking Temp | ℃ | ≥250 |

Thermal Conductibility | w/m.k | 0.038-0.06 |

Hydrophobic | % | ≥98 |

Moisture Rate | % | ≤5 |

Noise Resistant Coefficient (NRC) | 0.75 | |

Slag Inclusion Content | % | ≤0.3 |

GLASS WOOL BLANKET

Introduction

The glass wool blanket is applied for largelaying area. Besides the character of thermal insurance, it also has theperformances of shock absorption and acoustical isolation, especially for middleor low frequency sound. It also can cancel the noise and improve workingenvironment.

The glass wool blanket with aluminum foilsurface has good capability of heat radiation protection.

Technical Data

Item | Unit | Index |

Density | Kg/m3 | 10-32 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 10000-30000 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

This material can be freely cut inconstruction according to the shape required, mainly used in room,noise-canceling system, transportation, refrigerators and household electricappliances for noise canceling.

The blanket with aluminum foil is suitablefor high temperature shops, control room, inner wall of the machine shops, roomseparating and inner liners.

Package

Normal packing: Each roll is wrapped withvacuum plastic bag, and then in PE woven bag.

Special required package like PE BAG and PESHRINKED BAG can be made with additional charge.

GLASS WOOL PIPE

Introduction

As this material has the characters ofwater-proof, anti-corrosion and mildewing-proof, glass wool pipe is good atstopping condensation and freezing of the pipes.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 48-96 |

Thickness | mm | 25-90 |

Diameter | mm | 18mm-529mm(3/4 inch to 21 inch) |

Length | mm | 1 000,1 200 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

It is widely used in building, heating powerpipes, air conditioning and refrigerators for thermal insurance, such as hotwater pipes, steam pipes, electric power, petroleum and chemical industries.

Glass wool pipe faced with Alum Foil can beapplied to the surface for preventing moisture and radiation.

Package

Reasonable pieces will be packed withplastic bags or carton box, and then into container.

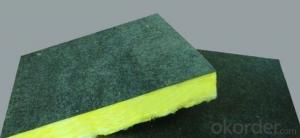

GLASS WOOL BOARD

Introduction

Glasswool board is a kind of plate productwith fixed strength after hot-setting of the centrifugal glass wool. It hasexcellent thermal insurance performance in the environment of both high and lowtemperature.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 24-96 |

Thickness | mm | 20-100 |

Width | mm | 600-1 200 |

Length | mm | 1 200,2 400 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

It is mainly used for the partition wall inthe high-grade building, such as ceiling, air conduit and inner wall forthermal insurance, machine shops for noise absorption, and metal ceiling forcontrol of moisture.

High density panels with laminated facingcan be used for Air-Conditioning Duct System.

Package

Reasonable pieces will be packed withplastic bags, and then into container.

- Q: What is the density of high-temperature glass fiber

- Density 2.4 ~ 2.7g / cm3 Glass fiber is used as reinforced materials in reinforcing plastic. the biggest feature is strong tensile strength. standard tensile strength is 6.3 ~ 6.9 g / d,in a wet state 5.4 ~ 5.8 g / d. Density 2.54. Good heat resistance. the tensile strength remains unchanged even if the temperature reaches as high as 300℃. It is high duty electrical insulation material. It is also used for thermal insulating and fireproof. it is only corroded by concentrated?alkaline,hydrofluoric?acid and concentrated phosphoric?acid.

- Q: Centrifugal glass wool board and polyurethane foam, which has better thermal insulation performance?

- It depends on where you use, if there is restrictions on the space, you'd better use centrifugal glass wool, and if the place is narrow, you can use foam materials, their performances are almost the same.

- Q: The advantages of glass wool board

- Features 1, the appearance quality: Surface is smooth, without the practical scars, stains damaged. 2, combustion performance: A level is non-combustible, 3. thermal endurance: 800 degrees. 4, hygroscopicity: & gt; 200% 5, capacity: ≤150 6. the oxygen index: 07, heat conductivity coefficient: 0.04 ~ 0.055 (w / mk) the product is technically in the process through the bonding pressure, trimming, notching, blanking, forming a tongue-and-groove type composite panels, with good integrity, high rigidity and shock resistance, shear resistance mechanical property and thermal insulation, insulation, sound insulation, moisture-proof and other characteristics.

- Q: How to use glass wool for filtering?

- It depends on the filtering materials, if the solid particles are large, you can directly use ordinary funnel but not filter paper, if solid particles are small, you can use filter paper, you can try to use a small amount of filtering materials, and decide in accordance to the filtrate state, the trial is necessary and you will know after lots of trials.

- Q: What is the construction process of external wall glass?wool?board?

- First, fix the glass wool to the wall with insulation supporting pins to prevent falling. A vapor barrier must be built on the surface of glass wool in order to prevent moisture condensation in the air within the glass wool, which may lead to the decrease of thermal insulation performance.

- Q: How is the insulation property of glass wool color steel?plate?

- It has poor insualtion property but good firepoof property. Rock wool insualtion board is recommended.

- Q: what is the specification of glass wool sound-absorbing board?

- General specifications include 600 * 600600 * 500 * 1200-1200/12000300/400 mm thickness is usually 14 to 22 mm. . Glass wool belongs to a category of glass fiber, and is a kind of man-made inorganic fiber. Glass wool is a kind of spongiform material shaped by making melten glass fibering, it's chemical content belongs to glass and is a kind of inorganic fiber. It has good molding, small bulk density, low thermal conductivity, good thermal insulation and heat insulation, good sound absorption, corrosion resistance and stable chemical performance. Centrifugal glass wool belongs to porous materials and has good sound absorption performance. Centrifugal glass wool can sound-absorbing reason is not due to the rough surface, but because of there exist a large number of internal and external connected tiny pore and holes. When sound waves enter on the centrifugal glass wool, sound waves can follow the internal pore into inner material, cause the vibration of air molecules in space. Because of the friction of air viscous resistance and air molecules and pore wall, sound energy is wore down after being transferred into heat energy.

- Q: Glass wool and pef air conditioning insulation material, which one is better?

- It's all right to use rubber and plastic, PEF or glass wool, but it is not recommended to use glass wool which has poor waterproof effect, and try to use rubber! Select the appropriate thickness according the local winter temperature, or it will be frozen if it is too thin in winter.

- Q: What is the difference among rock wool board, rock wool and glass wool?

- Rock wool, rock wool board, rock sliver collectively rock wool products products,they are the same products, like tea and tea water, glass wool material takes glass as the main materials, rock wool takes basalt as the main material, unit wieght of rock wool is larger than glass wool, the thermal insulation effect of glass wool is much better than rock wool, it seems that glass wool's price is more expensive, buy actually is cheaper than rock wool.

- Q: What is the uses of aluminum foil glass wool felt?

- Roll glass wool felt is coiled materials for large area coverage. It is not only thermal-insulating, but also can reduce shock and absorb sound,especially the medium and low frequency noise. It can help reduce the noise and improve the working environment. This material can be tailored based on the actual needs, mainly used for architectural indoor, muffler systems, transportation, refrigeration equipment, damping, sound absorption, noise reduction for the household appliances. Glass wool felt overlaid with aluminum foil has strong thermal radiation resistance. It is good lining material for high temperature workshops, control room, inner walls of machine room,compartment and flat top.

Send your message to us

Glass Wool Black Tissue Faced Blanket

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords