Black Particle Board OSB Phenolic Glue Oriented Strand Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

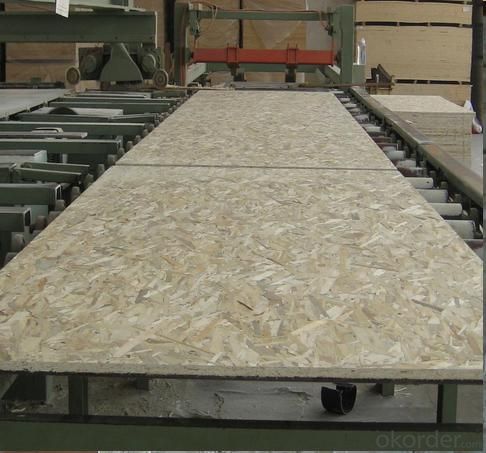

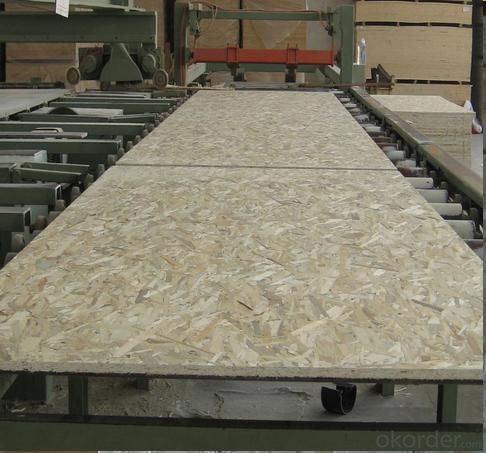

OSB also called waferboard,Sterling board, is the short name for Oriented Strand Board,it's made by small piece wood veneer(flakes) and cross pressed in the surface veneer and core veneer with high temperature and high pressure.

OSB with better features of much more durable, much stronger,as a good replacement of thicker plywood or solid wood plank,have been widely used in packing as packing box or pallet,decoration ,furniture as frame plank and building sites such as formwork panel,also specially in Canadian Style Housing Construction.

Characters:

environmentally friendly, using wood from small, fast growing trees locally or from the wasted veneer small pieces, less waste and better use of wood resources.

Products Details:

Detailed Specification:

Product name | OSB(Oriented Strand Board) OSB1: MR glue for package

| |

Size | 1220*2440,as you request | |

Thickness | 9mm to 30mm | |

Tolerance | ±0.5mm in the thickness,±0.2mm in the width and length | |

Glue | MR,E2 grade melamine,E1 grade melamine and WBP | |

Material | poplar, Combi | |

Supplying ability | 4000cbm/M | |

Density | 630--680kgs/cbm | |

Advantage | Tight construction and high strength; No rotten or decay, strong against corrosion and fire; Low formaldehyde emission; Good nailing strength, easy to be sawn, nailed, drilled,grooved, planed, polished; Good heat and sound resistant, easy to be coated. | |

Loading quantity | 9MM , 100pcs/pallet,16pallets/40'GP,1600pcs/40'GP | |

12MM,75pcs/pallet,16pallets/40'GP,1200pcs/40'GP | ||

14MM,65pcs/pallet,16pallets/40'GP,1040pcs/40'GP | ||

15MM,60pcs/pallets,16pallets/40'GP,960 pcs/40'GP | ||

16MM,57pcs/pallet,16pallets/40'GP,912pcs/40'GP | ||

18MM,50pcs/pallets,16pallets/40'GP,800 pcs/40'GP |

Usage | Can be used for roof decking, roof sarking, wall sheathing flooring, packing, hoarding, signboards and portable. |

Packaging | Inner with plastic bag, outside covered with plywood or cartons, then fastened with 4'x8' sheet iron and packed with pallets. |

Delivery | Within 15days after receiving prepayment or L/C |

FAQ:

Q1.What’s the main Material of OSB?

A1: poplar, birch, pine, hardwood

- Q: Some of advantages of particleboard

- with good sound and sound insulation performance; particleboard insulation, sound absorption;

- Q: Make the raw material of the particleboard

- The compound is ejected from the nozzle to form particles of 8 to 35 microns in diameter, forming an extremely thin and uniform continuous layer on the surface of the shavings

- Q: So for the particleboard formaldehyde release of the situation how to deal with it?

- The most commonly used method or window ventilation, is conducive to speed up the distribution of formaldehyde,

- Q: Market foreground and Industry development

- Particleboard due to poor quality and some other reasons, the market abandoned, many particleboard enterprises learn from the introduction of foreign advanced production lines and improve the level of technology,

- Q: How does the particleboard work?

- divided into intermittent production of the pressure method and the continuous production of extrusion, rolling method. The actual production to use the main pressure method.

- Q: Production of raw materials for particleboard

- Wood raw materials are taken from the forest cuttings, small diameter timber (usually less than 8 cm in diameter), harvesting residues and wood processing residues

- Q: What types of particleboard can be divided into?

- bending strength, vertical plate tensile strength (internal strength), grip nail force elasticity Modulus and modulus, etc

- Q: According to the use of points: Class A particleboard; Class B particleboard

- According to the manufacturing method points: flat pressure particle board; squeeze particleboard.

- Q: How to improve the particleboard market space

- In order to improve the quality of the particleboard and reduce the cost and improve the research and development capabilities

- Q: The product structure of the wood-based panel industry

- China's wood-based panel industry product structure is not reasonable, difficult to adapt to market demand.

Send your message to us

Black Particle Board OSB Phenolic Glue Oriented Strand Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords