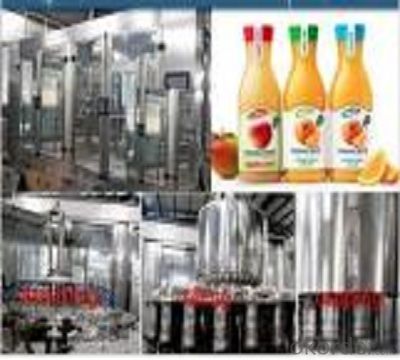

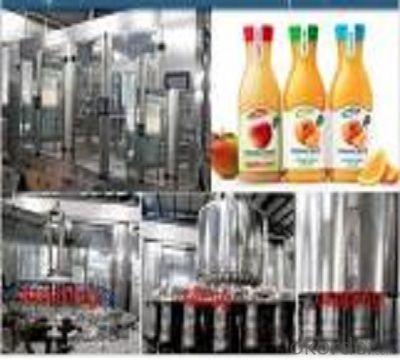

Beverage Production Line for bottle use

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Description

1)The machine is mainly used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic. The machine is used in filling juices, mineral water and purified water in bottles made of polyester and plastics.

2)The machine can also be used in hot filling if being installed with temperature controlling device. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles.

3)The filling operation is faster and more stablebecause the micro pressure filling operation of the new type is adopted. There the output and benefit of the machine is higher than the machines of the same specifications. The advanced OMRONprogrammed controller (PLC) is adopted to control the machine to run automatically while a transducer is used in the bottle -entering chains to adjust speeds and coordinated with the transducer of the main machine to make the operations of moving bottle forward steadily and reliably.

4)It is convenient tooperate with higher automation because every part of the machine is inspected to run with photo electricity, On the bases, the filling parts of the machine can be changed into filling methods of lower vacuum.

2.Main Features

Packaging & Delivery

Packaging Details:standard worthy wooden cases

Delivery Detail:30 working days

Company Management

Our company Our company has different department to finish different things,the sales in our company has been trained about the machines ,they are professional to help you.

Production Capacity

We can produce 10 complete lines ,30 machines per month.

3.Images

4.Specification

The filling operation is faster and more stablebecause the micro pressure filling operation of the new type is adopted. There the output and benefit of the machine is higher than the machines of the same specifications. The advanced OMRON programmed controller (PLC) is adopted to control the machine to run automatically while a transducer is used in the bottle -entering chains to adjust speeds and coordinated with the transducer of the main machine to make the operations of moving bottle forward steadily and reliably.

It is convenient tooperate with higher automation because every part of the machine is inspected to run with photo electricity, On the bases, the filling parts of the machine can be changed into filling methods of lower vacuum.

Quality Control

We have the single quality department,that make sure the material of the raw materials is good,and ensure the machine running smoothly.

Designed and Developed

According to the customer's requirements,and the beverage industry's development, The designing department design the most suitable machine for different area.The designing department make our company the leader of the beverage packing machine manufacture.

Export Market

Our machine has been sold to more than 40 countries,almost of the customers are satisfied with the machines and our service.

- Q: What is the design basis of automated packaging?! Just for today!

- Increase productivity and reduce process costGerman packaging machinery, especially beverages, beer filling machinery and food packaging machinery, with high speed, complete sets, high degree of automation and good reliability and so on. Beverage filling speed up to 1200 bottles / D, when the cigarette packaging 12000 / min.. Increasing the speed of the machine is a complex problem. The faster the piece production cost is, the higher the use area of the workshop is. In addition, the speed of the motor is limited, so do not think how fast, how fast. In general, the speed increase by 15%, 20%, will lead to a series of complex problems. In addition to increasing the speed, the productivity can be solved from other channels:1. continuous or long work. Packaging machinery works a batch type and continuous type, design, design should strive for continuous work, also can improve the productivity; one device may also have multiple production lines, the production of the same product or several different products, but must improve the reliability.2. reduce scrap rate and provide fault analysis system. The loss of waste to production is enormous, not only product loss, but also material loss. So try to force to reduce the rejection rate; packaging machinery sale should also provide maintenance services for the fault analysis system, the modal analysis is carried out to find fault, or through the Inter network for remote diagnosis, the maximum to meet customer needs. In the future, the packaging machinery will be further intelligent, that is, the equipment itself to find fault, to solve their own failure, to reduce waste rate and failure rate, so that the normal productivity can be improved.

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is suggested that displacement or velocity should be detected on the transport path of the membrane. Is a more reliable control signal. Of course, you can also detect the angular speed of the recovery drum, such as a code dial and other simple institutions.

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- Change a new one, in fact, the knife is very simple, and the ordinary knife is very cheap.If you don't understand, you can ask me

- Q: What are the main functions of packaging machinery and equipment?

- Such as cleaning, stacking and disassembly. In addition, also includes the measurement or the package seal etc.

- Q: Color code positioning of packaging machinery

- The use of the printed color packaging materials, photoelectric switch (available on the color electric eye tracking and positioning), through the control system to drive the stepper motor rotation and color according to the distance between the automatic stop, to complete and accurate packaging products logo.

- Q: Working principle of packing machine

- The working principle of the packing machine is simple. The packing material is first installed on the packing machine and installed

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packing machine? Should the packing of the tableware be contracted? Tak Cheung packing machinery, automatic heat shrinkable tableware packing machine can be considered

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- Ceramic wall and floor tile is a special term used in building ceramics industry. It refers to the ceramic tile used for paving internal walls, exterior walls and floors.It includes:Glazed tiles: white glazed tile, colored shaddock tile, embossed glazed tile, mottled glazed tile, patterned glazed tile, mural glazed tile.Floor tile: paving brick, red floor tile, ceramic mosaic tile (ceramic mosaic), ladder brick.The exterior wall tiles, glazed tiles, glazed tiles, imitation brick, brick from #.

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- If automated packaging, it depends on the factory situation, should not be from the user groups to start. If a small class of cosmetics do, then he will not say to buy a more than ten thousand or hundreds of thousands of automated equipment to pack ah. Automatic packing machine is certainly need a certain amount, a certain basis will be needed, or buy a mechanical automation a month the amount of packaging takes less than one hour, then buy this station automation machinery to do what? So, according to the automatic device, we can not start from the user groups, should be considered from the size of the factory.

- Q: What is a packaging machine?

- Well, before and after the associated processes, such as cleaning, stacking and disassembly. In addition, the package also includes the measurement or in the processes of stamp packages. Mechanical packaging products can improve productivity, reduce labor intensity

Send your message to us

Beverage Production Line for bottle use

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords