Vokes® NPP (Nanoporous insulation panels) core materials fumed Silica

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vokes® NPP (Nanoporous insulation panels)

Characteristics

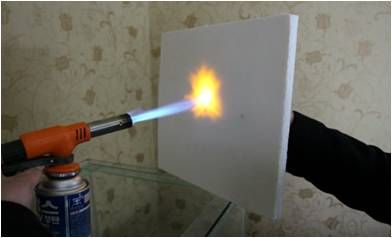

Vokes® NPP is an evacuated micro porous thermal

insulating panel with excellent insulating properties.

Vokes® NPP

The core material of

Vokes® NPP is fumed Silica board and noncombustible.

It is sealed into a high gas barrier film under vacuum.

Vokes® NPP

Application

Vokes® NPP is specially developed for insulation

applications where not much space is available but a

high thermal resistance is necessary. Mainly used in

high-temperature insulationMainly used in hightemperature

insulation.

Vokes® NPP

Vokes® NPP is a successful insulation element in the following areas:

• Industrial equipment insulation

• High temperature boiler insulation

• Thermal packaging (Medicine transport boxes, etc.)

• Appliance (Water boiler, etc.)

• Automotive (train, ship, air plains, etc.)

Advantage

• Insulation : Long-term application temperature reached -120℃-1200℃. Insulation at normal

temperature for 3-5 times the performance of traditional materials. Stable thermal conductivity at high

temperatures, Temperature at 300 ℃ insulation performance is 4-8 times that of traditional materials.

• Drastically reduced insulation thickness

• Thermal resistance :Particles constituting unit having a three-dimensional network structure,

will form many nanoporosity avoid sintering deformation.

• All purpose VIP with a long service life

•Corrosion resistant :Products made of an inorganic material, no soluble chloride ions, No

corrosion on equipment, pipe grassroots.

• Soundproofing/Seismic Performance :Acoustic noise reduction, buffer shock.

• Waterproof :Product nanoparticles themselves with super hydrophobic properties.

Product data

Surface color whiter

Geometry

Rectangular shape (without protruding

flanges*)

Density ≤300kg/m³

Thermal conductivity (Surface

temperature:℃)

50 0.016W/(m·k)

200 0.020W/(m·k)

300 0.023W/(m·k)

400 0.025W/(m·k)

500 0.033W/(m·k)

600 0.040W/(m·k)

700 0.050W/(m·k)

800 0.060W/(m·k)

Refractoriness >1200℃

cold crushing strength

(Compression 20%) ≥0.40MPa

permanent change in dimension on heating

(800℃×24h) ≤1.0%

Standard dimension (L x W)(mm) 250x600/500x600/1200x600

Thickness

10mm/15 mm/20

mm/25mm/30mm/40mm/50mm

Size tolerance

• 0 to 500 mm ±2 mm

Thickness tolerance ± 1 mm

Service life : extrapolated, depending on application up to 50.

Vokes® NPP Nanoporous insulation panel for industrial applications

Vokes® NPP surface can be a composite various materials(Heat shrinkable film, Glass fiber cloth,

Aluminum foil fiber cloth). Industrial furnace, Smelting industry(Steel, aluminum, melting pot, holding

furnace), Instrumentation, Petroleum & Chemical, Cold chain.

- Q: Glass curtain wall and floor between the gap how to deal with, seeking expert solution?

- 5mm galvanized iron clad bag> 100mm thick rock wool close to the curtain wall glass, reserved 2-3mm gap, weathering rubber seal, so as to avoid thermal expansion and contraction of glass broken, the treatment of the upper available Wooden feet to do the skirting, the outside can be painted stone or aluminum plate to do decoration. The purpose of the curtain wall is to prevent the fire from going up after the disaster and then the noise. Outside the side if the curtain wall glass transparent, then in the galvanized steel outside the surface brush decorative fluorocarbon paint.

- Q: Today, see the Christine plant more broken off the German vouchers fan of the CCTV news channel reported that the district energy-saving transformation, the workers are more tense, the first use is to meet the A-class thermal insulation materials, later said to be polyurethane insulation board, and then use the fire A little moment on the smoke, and quickly took the fire machine, then smoke did not burn out, repeated several times did not dare how, this insulation board really fire? More

- Polyurethane insulation board can reach B level.

- Q: Decorative materials Fireproof paint three degrees What does it mean

- Paint the number of Road, that is, times, three degrees, that is, three or three times

- Q: What is the fire insulation material

- Materials are: aluminum silicate fiber felt, inorganic mineral raw materials, perlite, glass fiber, ceramic fiber, mullite fiber, basalt fiber, high silicone fiber. Barrier insulation coating is a low thermal conductivity and high thermal resistance to achieve a thermal insulation coating. The most widely used barrier insulation insulation coating is a composite silicate insulation coating. This kind of coating is developed in the late 1980s, with different product names, such as composite magnesium aluminum silicate insulation coating, rare earth insulation coating, coated composite silicate insulation coating. It is made of inorganic and / or organic binder, insulation aggregate (such as sepiolite, vermiculite, perlite powder, etc.) and air entraining agent made of insulation coating. The performance requirements of such coatings can be found in GB / T-1998 "Silicate composite insulation coating". Composite silicate insulation coating Although the thermal conductivity is low, the cost is low, but the drying cycle is long, the impact resistance is weak, dry shrinkage, moisture absorption rate, low bond strength, poor decorative effect. This type of coating is currently used primarily for the casting of molds, tanks and pipes. This coating is currently not used for exterior insulation. In the future through the modified, is expected to be used for external wall insulation system.

- Q: Members colleagues, brother just into the Bank, it is necessary to use the Mylar film, what Mira is the material. Thank you more

- What is the difference between the three? We are more commonly used PC.

- Q: Please give a professional to answer ah

- You said the fireproof material refers to that piece of fireproof material? Is there any other request? For example, you said that the building fireproof material, it is generally frozen in the top of the world, there are rock wool, perlite, magnesite cement, cement, vacuum foil, etc., their performance to From the integrated point of view: fire rating, the use of temperature, fire time, waterproof, bending, wind pressure and so on.

- Q: Gypsum fire?

- Belong to a fireproof material.

- Q: Ul94v-0 refers to the fire level or a material

- UL94V-0 is UL94 standard V-0 flame retardant grade. Specified UL94 standard.

- Q: If not expensive to buy one of the best, but OKorder did not find. Because I have some important documents, documents, money, worry about living somewhere a day of fire. In case, I would like to put these important objects inside the bag can be fire. Not much of a thing, a folder size of the bag is enough. What materials can be used to make one way? Can also wrap the line, but can often open, not like the tape that ridge set up the plateau dry chop suck raft by the sample sealed. Thank you. More

- You can use concrete pouring a box ridge set hoarding plateau dry chop suck raft by the child, in addition to a concrete door can be, but relatively heavy, but can guarantee that will not be burned bad! Concrete is best at 20cm or more.

- Q: Class C fire door with what material

- Steel doors: 1.2 steel doors and door frames; 0.8 steel doors do fan panels. Doors filled with pearl slabs. Wooden door: long single worship bar of the lobster lice stiff frame with solid wood, but also splicing, flame retardant treatment, outsourcing fire board. The door also does the same.

Send your message to us

Vokes® NPP (Nanoporous insulation panels) core materials fumed Silica

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords