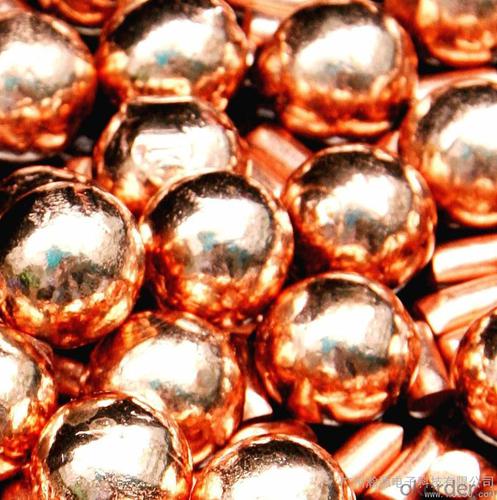

BEST QUALITY OF COPPER BALL WITH LOW PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 700000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1. Grade : G10-G100

2. We are factory

3. SGS approved

4. low price, high quality

5. material :brass,bronze and copper

About us

Brand Name | Place of Origin | Standard |

xinxin | Zhejiang China ( mainland) | SGS |

About brass ball

Product name | brass ball |

Material | brass,bronze and copper |

Diameter | 0.5 - 50.8mm / 0.2'' - 2'' |

Grade | G100 - G1000 |

Application | Mainly used for valves and craftwork , switch and aerosol dispensers , instrumentation , pressure gauges , water meter , electrical accessories |

package | Pallet , wooden cases or according to customers' requirements |

Standard | SGS |

Payment | L/C T/T D/P western union |

Delivery time | 10 - 15 days after receiving the advance payment |

Chemical Composition

material | Cu | Fe | Pb | Sb | Bi | P | Other | Zn |

59-1 | 57.0-60.0 | 0.20 | 0.80 | 0.50 | 0.01 | 0.003 | Mn0.02 | Remainder |

H62 | 60.5-63.5 | ≤0.15 | ≤0.08 | ≤0.005 | ≤0.002 | ≤0.01 | ≤0.5 | Remainder |

- Q: How to calculate the price of casting parts?

- Cost of raw materials + electricity (fuel) costs + workers' wages + managers' wages + transport costs + raw materials burned + accessories costs + equipment maintenance depreciation costs + management fees + tax. The most convenient, the raw material market price plus 2000 yuan, plus you want profits on the line.

- Q: What are the requirements for casting steel castings?

- 2, the plane should be placed on the following.3, thin parts should be placed below.

- Q: How to distinguish the forging parts and casting parts accurately

- To distinguish from the use of materialsForging materials are mainly made of carbon steel and alloy steel of various components, followed by aluminum, magnesium, titanium, copper and their alloys. The original state of the material is rod, ingot, metal powder and liquid metal. The materials needed for casting are mostly metal, wood, fuel, molding materials and so on. In contrast, the forging parts rarely produce dust, harmful gas and noise, etc., and play a more obvious role in environmental protection. Of course, because of this, the price of forged parts on the market is higher than that of castings.

- Q: What is the casting material?

- Gray iron, carbon steel, low alloy steel, ductile iron, stainless steel, Aluminum Alloy can all be cast out

- Q: What is the difference between casting and stamping parts?

- The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning and rectification are several main stamping processes. The difference between stamping parts and castings: with thin, uniform, light, strong features, stamping can be produced by other methods difficult to make, with stiffeners, ribs, UPS or flanging of the workpiece, to improve its rigidity. Due to the use of precision molds, the workpiece accuracy up to microns, and repeated high precision, specifications consistent, you can punch out of the hole, lug and so on.

- Q: Where is the precision casting factory?

- Everywhere is. Look what you want to do

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- Yes, the cast aluminium is polarized and gray, but the key problem is to guarantee the quality of the aluminium casting, and the quality of the other aluminium casting is not good.

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- For example Changchun FAW, under a casting, two casting and other casting plant, but there are more than half of all outsourcing in Tianjin Hebei Shandong purchase, many automobile enterprises to casting foundry.

- Q: What are the general technical requirements for casting parts?

- According to the national standard GB/T 9438, there are 8 aspects: 1. chemical composition; 2. delivery status; 3. mechanical properties; 4. dimensional tolerances; 5. weight tolerances; 6. appearance quality; 7. internal quality; 8. casting salvage.

- Q: How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

Send your message to us

BEST QUALITY OF COPPER BALL WITH LOW PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 700000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords