Best Prepainted Galvanized steel Coil JIW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 11 m.t.

- Supply Capability:

- 11 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Prepainted Galvanized steel Coil :

With Gi as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called prepainted galvanized steel ( PPGI) .Prepainted galvanized steel is good capable of decoration ,molding,corrosion resistance The carbon in typical steel alloys may contribute up to 2.1% of its weight. Varying the amount of alloying elements, their formation in the steel either as solute elements, or as precipitated phases, retards the movement of those dislocations that make iron comparatively ductile and weak, and thus controls qualities such as the hardness, ductility, and tensile strength of the resulting steel. Steel's strength compared to pure iron is only possible at the expense of ductility, of which iron has an excess.

2.Main Features of Prepainted Galvanized steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

Although steel had been produced in bloomery furnaces for thousands of years, steel's use expanded extensively after more efficient production methods were devised in the 17th century for blister steel and then crucible steel. With the invention of the Bessemer process in the mid-19th century, a new era of mass-produced steel began. This was followed by Siemens-Martin process and then Gilchrist-Thomas process that refined the quality of steel. With their introductions, mild steel replacedwrought iron.

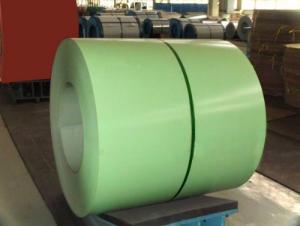

3.Prepainted Galvanized steel Coil Images

4.Prepainted Galvanized steel Coil Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Prepainted Galvanized steel Coi

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.how long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. what is your moq

Normally our moq is 25per size ,but it is up to different size

- Q: How are steel strips processed for heat dissipation?

- Heat dissipation in steel strips can be achieved through various means. One commonly used technique involves subjecting the strips to a heat treat process, which entails controlled heating and cooling cycles. This process modifies the steel's microstructure, increasing its resistance to heat and improving its ability to dissipate it. Another approach involves applying surface coatings or treatments. Coatings of thermally conductive materials like copper or aluminum can be added to the steel strips. These coatings enhance the steel's heat dissipation properties, enabling efficient transfer of heat away from the source. Moreover, heat sinks can be utilized in the processing of steel strips. These devices are designed to absorb and dissipate heat, typically made from materials with high thermal conductivity. They can be attached to the steel strips to enhance heat dissipation efficiency. In addition to the aforementioned methods, the design and shape of the steel strips also impact heat dissipation. Incorporating features like fins or grooves increases the surface area of the strips, promoting better airflow and enhancing overall heat dissipation capabilities. In summary, achieving effective heat dissipation in steel strips requires a combination of heat treatments, coatings, heat sinks, and design modifications. These techniques collaborate to improve the steel's thermal properties, ensuring efficient heat dissipation and preventing excessive temperature buildup.

- Q: How are steel strips stacked for storage?

- Steel strips are typically stacked for storage by placing them vertically on top of each other, forming a neat and organized stack. This method of stacking allows for easy access to individual strips when needed, as well as efficient use of storage space. The strips are usually aligned with each other and secured with banding or strapping to prevent them from shifting or falling during storage or transportation. Additionally, wooden or metal separators may be inserted between the layers to provide stability and prevent damage. The height of the stack is determined by the weight-bearing capacity of the storage area and the size and weight of the steel strips. It is important to ensure that the stack is not too high to avoid the risk of toppling over. Overall, careful and proper stacking of steel strips is crucial to maintain their integrity and facilitate their efficient retrieval when required.

- Q: Can steel strips be used in the production of kitchen utensils?

- Yes, steel strips can be used in the production of kitchen utensils. Steel is a common material choice for utensils due to its strength, durability, and resistance to corrosion. Steel strips can be shaped and formed into various kitchen utensils like knives, spoons, forks, and spatulas, providing a reliable and long-lasting option for culinary purposes.

- Q: Can steel strips be used in the production of automotive suspension components?

- Yes, steel strips can be used in the production of automotive suspension components. Steel strips are commonly used in the manufacturing of various automotive parts, including suspension components, due to their high strength, durability, and ability to withstand heavy loads and impacts. They provide the necessary rigidity and support required for suspension systems, ensuring stability, control, and proper functioning of the vehicle's suspension.

- Q: How are steel strips used in the production of metal signs?

- Steel strips are commonly used in the production of metal signs as they offer several advantages. Firstly, steel strips provide a strong and durable base for the sign, ensuring its longevity and resistance to weather elements. This is important, especially for outdoor signs that are exposed to rain, wind, and sunlight. Additionally, steel strips can be easily shaped and bent into various forms, allowing for the creation of different sign designs. This flexibility makes steel strips a versatile material for sign manufacturers, enabling them to create intricate and custom-made signs. Moreover, steel strips can be coated with different finishes, such as paints, coatings, or laminates, to enhance their appearance and protect them from corrosion. This helps to maintain the aesthetic appeal of the sign and prolong its lifespan. Furthermore, steel strips are often used as a substrate for applying graphics, lettering, or other decorative elements on the sign. They provide a smooth and flat surface, allowing for precise and high-quality printing or application of vinyl decals. Lastly, steel strips can also be easily attached to various mounting systems, such as brackets, frames, or posts, making it convenient to install the metal signs in different locations. In summary, steel strips are an essential component in the production of metal signs due to their strength, versatility, ability to be coated, substrate properties, and ease of attachment. These qualities make steel strips an ideal choice for manufacturing metal signs that are durable, visually appealing, and suitable for various applications.

- Q: How are steel strips protected against corrosion from saltwater?

- Steel strips are protected against corrosion from saltwater through various methods such as applying protective coatings like zinc or epoxy, galvanizing the steel, or using stainless steel which is naturally resistant to corrosion.

- Q: What are the factors that affect the fatigue resistance of steel strips?

- There are several factors that can affect the fatigue resistance of steel strips, including the material's composition and microstructure, the presence of any defects or imperfections, the level of applied stress, the frequency and amplitude of cyclic loading, and the environmental conditions in which the steel strips are used.

- Q: Are steel strips suitable for construction purposes?

- Yes, steel strips are suitable for construction purposes. Steel strips are strong, durable, and resistant to corrosion, making them an excellent choice for various construction applications such as framing, support structures, and reinforcement. They provide stability and structural integrity to buildings and can withstand heavy loads, making them ideal for construction purposes.

- Q: Can steel strips be customized in terms of thickness, width, and length?

- Yes, steel strips can be customized in terms of thickness, width, and length. Customization allows for the production of steel strips that meet specific requirements and can be tailored to fit various applications and industries.

- Q: What is the elongation percentage of steel strips?

- The elongation percentage of steel strips denotes the extent to which a steel strip can stretch or deform before it reaches its breaking point. It serves as a gauge of the steel strip's ductility or its capacity to endure deformation without fracturing. Typically, the elongation percentage is expressed as a proportion of the strip's original length. The elongation percentage of steel strips can vary depending on several factors including the steel's composition, the manufacturing process, and any heat treatments employed. Generally, steel strips possess a relatively elevated elongation percentage, rendering them suitable for applications necessitating flexibility and the ability to withstand bending or shaping without breaking. For instance, in the case of mild steel, commonly utilized in strip form, the elongation percentage can range from 20% to 40% or even higher. This implies that a mild steel strip with an original length of 100mm can stretch up to 40mm or more before fracturing. However, it is crucial to acknowledge that the elongation percentage can be influenced by external aspects such as temperature, strain rate, and the presence of impurities or defects in the steel. The elongation percentage of steel strips is a significant mechanical property that is considered in the design and selection of materials for diverse applications. It holds particular relevance in industries like automotive, construction, and manufacturing, where a material's ability to deform without failure is paramount.

Send your message to us

Best Prepainted Galvanized steel Coil JIW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 11 m.t.

- Supply Capability:

- 11 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords