Parts For Crushing Plant

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 Sets set

- Supply Capability:

- 1000 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Parts for Crushing Plant:

Used for mining and construction part

Material: carbon steel

Process: silicon sol process

Processing method: investment casting, CNC machining and assembling

Packaging: standard export packaging (plastic bag and carton) or according customer's request

High quality and reasonable price

Usage of Parts for Crushing Plant:

jaw plate for crusher is easy to install, operate and maintain. As per feedback, our experts will make continuous improvements on our products to meet customers' changing needs. Every feature of Zenith jaw plate for crusher has been carefully designed to provide superior quality and performance. It is widely used in fields of mining, metallurgy, construction, smelting, hydropower and chemical industries etc. Zentih has competive jaw plate for crusher price for you.During operation, the motor drives the eccentric shaft shells to turn around through a horizontal axle and a pair of bevel gear. The axle of crushing cone swings with the force of eccentric shaft shell so that the surface of the crusing wall is close to the roll mortar wall from time to time. In this way, the ores and rocks will be pressed and crooked and crushed.

1) Material: high manganese steel: Mn13%, Mn18%, Mn24% High chromium iron: Cr20, Cr24 up Carbon Steel HT200 QT400-15

2) Use: Machinery in metal recovery smash, mine, metallurgy, chemical industry, cement, petroleum etc.

3) Production quality testing: High frequency infrared carbon & sulfur analyzer, Metallographic microscope, Machinery performance testing equipment, Hardness testing equipment, Ultrasonic inspection equipment

4) Easy installation: The anti-abrasion block is a semi-permanent part, which is easy for replacement.

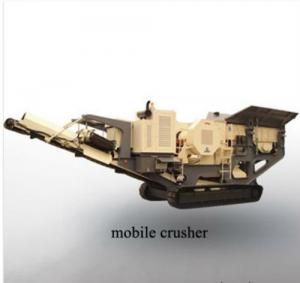

Picture of Parts for Crushing Plant:

- Q: Why do you say that Xinxiang is the hometown of vibrating screens?

- Xinxiang vibrating screen manufacturers accounted for about 70% of the total amount of the country.

- Q: What is the difference between exciter and vibrating motor?

- First of all, the vibration motor is also the motor, but why should we call the vibration motor? Because of its vibration exciter, the principle is the same as the same, ha ha, nonsense, work principle and application of the next let me talk in detail about the vibration of the motor, I believe you can understand, give me ah.

- Q: What are the precautions for using a linear vibrating screen?

- When working with a linear screen, the vibrating motor is first started, and the whole sieve body moves stably and then is added to the material to prevent the blockage of material and influence the screening efficiency.

- Q: How many Xinxiang vibrating screens are there now? How many are there on a scale?

- Xinxiang vibration industry has no end of my thoughts about a company name and then go online to search under almost all vibration industry

- Q: Can the linear vibrating screen not be horizontally placed? How big is the dip angle?

- The effect of horizontal placement is that the performance parameters of the screening machine can be rationally configured to obtain good material running speed and processing capacity and higher screening efficiency.

- Q: How do I clean the shaker?

- Different materials, cleaning methods are also different

- Q: Why are the vibrating screens divided by use?

- The vibrating screen can be divided into laboratory vibrating screen and industrial vibrating screen according to its use

- Q: How to install ultrasonic vibrating screen mesh

- 1, the steps are the same as above;2. Place the installed screen flat on the clean surface and place the rack on the screen. Notice: the direction of the grid the position of the transducer is upwards;3, beyond the screen edge grid from the grid to roll up and tighten, with instant glue (502 glue can) will roll up the screen in the back of the grid point stick, the tension in the grid on a flat screen;4. The sealing aprons are installed on the grid;5. The net rack is mounted on the sieve machine, pressing the upper frame and locking the bundle ring. (while tightening the tie ring nut, the rubber hammer is used to knock the circumference of the bundle ring evenly so that the force is evenly distributed), and the screen is pressed on the grid by the upper frame;In 6, the bonded surface uniform coating, glue and screen on your fingers, make the glue evenly dispersed, about 30 minutes in the glue again, after the glue completely dry can be used.

- Q: What is the vibration of the shaker?

- The center of gravity of the vibrating screen is not on the exciting force line, causing the sieve body to swing. In the design, it is necessary to find the center of gravity of the screen, so that the force line through the center of gravity will do. The sieve is ready to swing and can be adjusted with a counterweight.

- Q: What kind of vibrating screen is used in the coal preparation plant?

- Banana bananas are much used now. There are coal classification with circular vibrating screen, banana screen.Desliming can be done with a straight screen (with a tilt angle) or a banana screen.There are many kinds of sieves, such as: back screen, string screen, roller screen and so on. They are also used by coal preparation plants.

Send your message to us

Parts For Crushing Plant

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 Sets set

- Supply Capability:

- 1000 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords