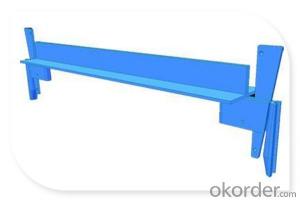

Australia Kwikstage Scaffold System Parts /Transom Scaffolding CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Australia Kwikstage Scaffold System Parts /Transom Scaffolding

Type:

Material:

Construction Properties:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Place of Origin:

Surface:

Material.:

Thickness:

Descriptions of Australia Kwikstage Scaffold System Parts /Transom Scaffolding

Kwikstage Scaffolding is a multi-purpose modular scaffold system which can be used for all forms of access and support structures in the building and construction industries, ship buliding, offshore construction and industrial maintennace.

Details of Metal kwikstage Scaffolding

1. Metal kwikstage scaffolding system is a new type of selflock scaffolding which is very popular in Oceanian,African construction.

2. Metal kwikstage scaffolding System is suitable for both inside concrete slab supporting and outside masonry Construction multi-purpose for construction.

3. Metal kwikstage scaffolding systemstandard is weld with a plate every 600mm which can join ledgers at 90 degree.

4. Metal kwikstage scaffolding system ledger is a horizontal member with a blade at each end for insertion into the standard plate.

5. kwikstage scaffolding system is quick to erect and strip which has completely replaced other scaffolding.

The Accessories of Australia Kwikstage Scaffold System

The main items of Kwikstage scaffolding system

ITEMS SPECIFICATION WEIGHT STANDARD

(VERTICAL)48.3*4.0*3000/2500/2000/1500/1000mm

painted/hot dip galvanized/ect.

steel pipe16.94/14.34/11.53/8.86/6.13kg LEDGER

(HORIZONTAL)48.3*3.2*2400/1800/1200/700mm

painted/hot dip galvanized/etc.

steel pipe9.1/6.85/5.13/3.24kg TRANSOM 2400/1800/1200/700mm

painted/hot dip galvanized/etc.19.92/12.08/10.79/7.79kg BRACE 2400*2000mm/2500/3000mm

pained/hot dip galvanized/etc.9.38/10.35/11.41kg HOPUP BRACKET one board/two board/three board

painted/hot dip galvanized/etc.1.84/4.99/8.58kg The other items of Kwikstage scaffolding system

TIE BAR 2400/1800/1200/700mm

painted/hot dip galvanized/etc.5.41/4.15/2.77/1.72kg STEEL BOARD 2400/1800/1200/700mm

painted/hot dip galvanized/etc.14.5/10.93/7.68/4.94kg END TOE BOARD BRACKET as normal specification or as customers' drawing

painted/hot dip galvanized/etc.1.12kg TOE BOARD BRACKET as normal specification or as customers' drawing

painted/hot dip galvanized/etc.0.72kg BASE JACK and U HEAD 38*4.0*650mm/u head

painted/hot dip galvanized/etc.3.69/4.63kg FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: What issues need to pay attention to the construction of high-level scaffolding

- The use of the end of the scaffolding (including the construction of accessories) should be returned to the library, classified storage. Open dumps, the site should be smooth, good drainage, under the support pad, and covered with a sheet, accessories, parts should be stored indoors. Wuxi Dongfang scaffolding scaffolding factory products strictly according to JOD-1999 and OD15001-1205 standards, a type of mobile scaffolding scaffolding, scaffolding, roulette scaffolding, scaffolding and scaffolding accessories.

- Q: i have lived in york for ten years and have been told many times that the minster in york has had scaffolding up for decades and that it has to stay there for political or religious reason there is never any work done or indeed workers on the scaffolding. can anyone shed any light on the matter for me or is it just an urban myth and nothing more than on going restoration.

- Eee, by gum, Petey.....all ye hed te do wuz GOOGLE scaffolding on york minster, in'it? And y'eed a learned they's FIXING it reckon on it tekkin 'em ten year or moore!

- Q: i just got it like 3 days ago and its no signs of infection and im just worried it might get that way. ive been reading online about people who got infections and people who had all this crap happen. what do i need to do to stop one from coming i mean i use contact solution and cotton swabs wipe it down with wet ones and clean it when i sweat and turn it twice a day.. im always careful about keeping it clean im a neat clean freak but is there anything else i can do to stop infection from coming

- sounds like what your doing is fine. just keep it clean that's basically all you can do.

- Q: Do the external wall decoration (from the top down to do) scaffolding is to wait until after the completion of the indoor and outdoor decoration before the demolition?If the first interior decoration, can make a layer of a layer of it is to remove all the work finished I mean I finished all the interior decoration, wall decoration only, then I do a wall decoration on the demolition of a layer of scaffolding, this site useful no

- Two, removal of scaffolding, should meet the following requirements:1, the demolition work must be from top to bottom layer by layer, prohibited from top to bottom operation at the same time;2, even the wall must be removed with the scaffolding layer by layer, is strictly prohibited even after the first wall or a few layers of the demolition of the demolition of the scaffolding; demolition of the height difference should not be greater than 2 steps, such as the height difference is greater than the step, should be added to strengthen the wall;3, when the scaffolding down to the bottom of a long rod height (about 6.5m), should be in the appropriate position to set up temporary support reinforcement, and then dismantle the wall;4, when the scaffolding to take the sub section, the demolition of the sub elevation, the demolition of the scaffold should not be removed at both ends, should be added to the wall and lateral oblique reinforcement.

- Q: Scaffolding installation process, construction preparation

- Construction preparation(1): steel pipe should be consistent with current national standard "carbon structural steel" (GB/T700) regulations Q235- grade steel; new steel pipe should be the product quality certificate; steel surface should be flat and smooth, no cracks, scarring, delamination, dislocation, bend, burr, indentation and scratch depth, pipe diameter deviation not more than -0.5mm, the wall thickness deviation not greater than -0.5mm, cutting slope deviation not greater than 1.7mm, the steel surface should be brushed with antirust paint; old steel corrosion depth not greater than 0.5mm, more than the prescribed steel shall not be used.(2): buckle made of malleable iron fasteners, the material should be consistent with current national standard "steel pipe scaffolding fasteners" (GB15831) regulations; old buckle inspect before use, shall not have cracks, deformation, bolt appear smooth silk must be replaced; new and old fastener must brush good antirust paint.(3) foot board: the use of 4m long wooden foot board; foot width of not less than 200mm, the thickness is not less than 50mm, both ends should be set with a diameter of 4mm galvanized steel hoop two; rotten feet can not be used.(4) safety net, paint.(5) after the inspection and acceptance of the above parts have been classified and piled up in a neat and orderly manner, no water can be accumulated.2, scaffolding erection and removal(1) scaffold erection

- Q: The outer hanging scaffold board 12 embedded parts embedded in the crack?

- The outer hanging scaffold board 12 embedded parts embedded in the crack, because the outer hanging scaffold embedded generally should be buried in the beam, and checking of the beam.

- Q: How many time was Hester Prynne on the scaffold? why was she on it each time? What about the time when pearl and dimmesdale was on it with her? HELP!!!

- she was on it 3 times once as her punishment for adultery. then at night with pearl and dimmesdale when he was acknowledging his crime and then at the end to hear what is happening at the election or whatever it was. she was the only one up their (putting her at a higher level then the rest of society) and she was still there with dimmesdale when he died.

- Q: Construction, outdoor double scaffolding a square meter how many meters of steel pipe and how much?

- According to the height of their own construction plans, according to the construction area of 1 square root, fasteners ranging from docking fasteners and rotating fasteners, rotating fasteners should be every square of the 3 bar, a detailed look at the old construction workers

- Q: improper design of formwork and scaffolding, not adequate braces and supports, improper handling, corrosion of material is several factor of formwork and scaffolding failure. it is estimated that more than 3000 accidents involving falls from scaffolds and 30 fatalities

- I believe that you have covered it all. Improper handling covers my first thought; workers carelessness by not following safety guidlines

- Q: Which accessories are included in a movable scaffold

- (1) single specification steel pipe scaffold. It only uses a steel pipe specifications, such as steel tubular scaffolding, welded steel pipe using only 48 * 3.5.(2) scaffold with various specifications of steel pipe. The utility model is composed of two or more steel pipes of different specifications, such as a door type scaffold.(3) steel scaffolding. As to the steel pipe, and combined with other type of steel pieces composed of scaffolding, such as the channel has a base in the backwater or scaffolding, connecting steel scaffolding and so on.

Send your message to us

Australia Kwikstage Scaffold System Parts /Transom Scaffolding CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords