Australia Kwikstage Scaffold System Parts /Scaffolding Standard CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Australia Kwikstage Scaffold System Parts /Scaffolding Standard

Type:

Material:

Construction Properties:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Place of Origin:

Surface:

Material.:

Thickness:

Descriptions of Australia Kwikstage Scaffold System Parts / Scaffolding Standard

Kwikstage Scaffolding is a multi-purpose modular scaffold system which can be used for all forms of access and support structures in the building and construction industries, ship buliding, offshore construction and industrial maintennace.

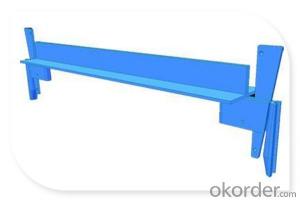

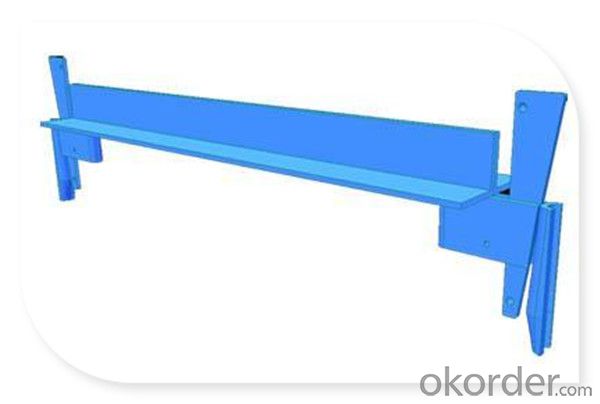

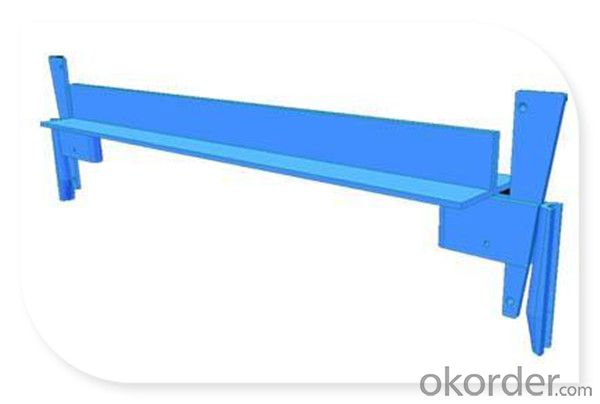

Details of Metal kwikstage Scaffolding

1. Metal kwikstage scaffolding system is a new type of selflock scaffolding which is very popular in Oceanian,African construction.

2. Metal kwikstage scaffolding System is suitable for both inside concrete slab supporting and outside masonry Construction multi-purpose for construction.

3. Metal kwikstage scaffolding systemstandard is weld with a plate every 600mm which can join ledgers at 90 degree.

4. Metal kwikstage scaffolding system ledger is a horizontal member with a blade at each end for insertion into the standard plate.

5. kwikstage scaffolding system is quick to erect and strip which has completely replaced other scaffolding.

The Accessories of Australia Kwikstage Scaffold System

The main items of Kwikstage scaffolding system

ITEMS SPECIFICATION WEIGHT STANDARD

(VERTICAL)48.3*4.0*3000/2500/2000/1500/1000mm

painted/hot dip galvanized/ect.

steel pipe16.94/14.34/11.53/8.86/6.13kg LEDGER

(HORIZONTAL)48.3*3.2*2400/1800/1200/700mm

painted/hot dip galvanized/etc.

steel pipe9.1/6.85/5.13/3.24kg TRANSOM 2400/1800/1200/700mm

painted/hot dip galvanized/etc.19.92/12.08/10.79/7.79kg BRACE 2400*2000mm/2500/3000mm

pained/hot dip galvanized/etc.9.38/10.35/11.41kg HOPUP BRACKET one board/two board/three board

painted/hot dip galvanized/etc.1.84/4.99/8.58kg The other items of Kwikstage scaffolding system

TIE BAR 2400/1800/1200/700mm

painted/hot dip galvanized/etc.5.41/4.15/2.77/1.72kg STEEL BOARD 2400/1800/1200/700mm

painted/hot dip galvanized/etc.14.5/10.93/7.68/4.94kg END TOE BOARD BRACKET as normal specification or as customers' drawing

painted/hot dip galvanized/etc.1.12kg TOE BOARD BRACKET as normal specification or as customers' drawing

painted/hot dip galvanized/etc.0.72kg BASE JACK and U HEAD 38*4.0*650mm/u head

painted/hot dip galvanized/etc.3.69/4.63kg FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: How to calculate the rental price of portal scaffolding

- Under normal circumstances, the small local rental price: 2.5-3.0 yuan / set / day

- Q: i have my nose pierced and am thinking about getting a scaffold cartilage piercing, but am affraid because your cartilage is so tough! and i know it depends on the person when it comes to pain, but just compairing it to a nose piercing? (when i got my nose pierced i cried, but once they finished piercing it, i wasn't in anymore pain)

- ive just had scaffolding done, and it was quite painful, far more painful than i was told. they just stab through your ear with a needle, but i didn't think it was that bad. not as bad as getting your nose done. but it was very sore and painful to touch for days after. hope this helps :) X

- Q: Can you identify Scaffold Grade Aluminum tubing by looking at it.?

- The grade or type of Aluminum Alloy materials can not be identified visually because they are almost all the same in appearance. Normally these materials are marked with there Alloy number or designation like, 6061- T6, at certain intervals so that users can distinguish them.

- Q: I got my scaffold piercing 6 days ago, with titanium, and it was fine until yesterday.I had a couple of nights out and might have knocked it a few times, but yesterday it was swollen, red, throbbing and very painful. There is no liquid coming from it. It seems to have got worse today.I have been following the aftercare advice and cleaning it several times a day with rock salt solution and (up until yesterday) savlon antiseptic spray. Is it just irritated or is it infected? How long should I wait before I go to the doctor? If it is infected, will I have to take it out or just take antibiotics?Thanks!

- It's irritated. If it was infected, it would be oozing green or yellow gunk:) If it gets to that point, go to the doctor. Until then, just treat is regularly with salt solution:) Hope this helped!

- Q: by scaffolding ?

- It's a rhetorical question, maybe the girl is held up so well that it could have been something else holding her up there

- Q: Can anyone give a very brief description on all three scaffold scenes in The Scarlet Letter?

- oh dang u have to read that story too ! man i had to read it and watch the movie ! so boring. What grade are u in ?

- Q: Where can I source scaffolding steel/aluminium planks with rubber end caps?I am having much difficultly finding anything, can you assist?Thank you in advance.

- Maybe something like a window washers scafolding planks...?

- Q: Im a wimp for pain and im looking to get my scaffolding done. i want to know how painful it isI already have both lobs pierced and stretched to an 8mm, will the pain be similar to that?

- You sound like you have a low tolerance for pain if you say you're a wimp haha, which means yeah it'll probably hurt you. It'll hurt more than the lobes because it's cartilage, and for the same reason you'll hear a popping noise as the hole is made. You won't be taken over by deathly pain or anything like that, it'll probably be sensitive for a few days after too so careful not to knock it against anyone/ anything. But if you want it bad enough, the pain will be bearable.

- Q: I'm interested in a scaffold career in the oil rigs in the north sea

- Sorry if I'm not serious, but go to Hong Kong as there they do scaffolding made of bamboo and 170 floors high ,2000mtrs above the sea level... Now that is serious...

- Q: male scaffolders only if i was swinging on the scaffold would ya stomp on my fingers with ya workboots on?

- Had a hooker climb up the ladder to the 3ed floor one time....didn't stay long though!

Send your message to us

Australia Kwikstage Scaffold System Parts /Scaffolding Standard CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords