ASTM A 106 Seamless Steel Pipe/Seamless Pipe/API Seamless Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are company that have many years experience and professional manager team and engineer team and sales team, sure we will provide you high quality of pipe and professioanl service.

Seamless pipe possesses a hollow section and without seam around the strip steel. It is made with solid bar or steel ingot by perforating machine. As the facture process does not include any welding, seamless pipes are considered to be stronger and more durable. Generally speaking, seamless pipe has better pressure resistance and security than other classifications, and was usually more easily available than welded pipe.

2、Main Features of the Seamless Pipe:

• High working accuracy

• High strength

• Small inertia resistance

• Strong therming dissipine ability

• Good appearance

• Reasonble price

3、Seamless Pipe Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range: OD: 21.3-610mm, WT:6-70mm, length:6-12m or according to the requirement of clients.

3) Executive standards: GB, ASME API5L.ASTM A 106/A53,Despite of the above standards, we can also supply seamless steel pipe with standard of DIN, JIS, and so on, and also develop new products according to the requirements of our clients!

4) Surface: black lacquered, varnish coating or galvanized.

5) Ends: Beveled or square cut, plastic capped, painted.

6) Packing: bundles wrapped with strong steel strip, seaworthy packing.

4、Packaging & Delivery:

Packaging Details: | seaworthy package, bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe:

①How is the quality of your products?

We have many years business experience in this area, and we have professional engineer and manager team and sure we can provide you high quality production and professional service.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

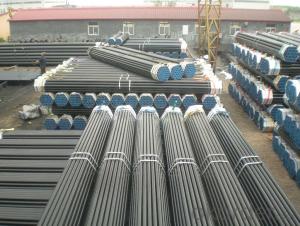

6、Seamless Pipe Images:

- Q: How are steel pipes classified based on their schedule?

- Steel pipes are classified based on their schedule, which refers to the thickness of the pipe walls. The schedule classification system includes different numerical values, such as Schedule 10, Schedule 40, and Schedule 80, to categorize pipes with varying wall thicknesses.

- Q: What are the different shapes available for steel pipes?

- There are several different shapes available for steel pipes, including round, square, rectangular, and oval.

- Q: Are the welded and galvanized tubes the same weight?

- The difference is that because zinc has weight, even if the difference is very small, there are also differences,Galvanized pipe weight is basically the same about 1.06 of the welded tube, of course, you can artificially ignored.

- Q: Can steel pipes be used for transporting drinking water?

- Yes, steel pipes can be used for transporting drinking water. Steel pipes are commonly used in water distribution systems and have been used for many years. They are known for their durability, strength, and resistance to corrosion. However, it is important to ensure that the steel pipes used for transporting drinking water are properly coated or lined to prevent any potential contamination from the metal. Additionally, regular inspections and maintenance should be carried out to ensure the integrity of the pipes and to prevent any leaks or breaks that could compromise the quality of the water.

- Q: Can steel pipes be used for gas transportation?

- Yes, steel pipes can be used for gas transportation. Steel pipes are commonly used for the transportation of natural gas, propane, and other gases due to their high strength, durability, and resistance to corrosion. They can effectively withstand high pressure and extreme temperatures, making them a reliable choice for gas transportation systems.

- Q: Can steel pipes be used for underground water supply pipelines?

- Yes, steel pipes can be used for underground water supply pipelines. Steel pipes are strong, durable, and resistant to corrosion, making them suitable for underground applications. They are often used for water supply pipelines due to their high strength and ability to withstand high pressure and load. Additionally, steel pipes can be welded together, ensuring leak-free connections, and are available in various sizes to accommodate different water supply needs.

- Q: Can steel pipes be used for solar energy systems?

- Yes, steel pipes can be used for solar energy systems. Steel pipes are commonly used for the construction of solar water heating systems and solar thermal collectors. They are durable, resistant to corrosion, and can efficiently transport hot water or heat transfer fluids, making them suitable for various solar energy applications.

- Q: What are the dimensions of steel pipes?

- The dimensions of steel pipes can vary depending on the specific requirements and industry standards. However, steel pipes typically have standardized dimensions in terms of their outer diameter (OD), wall thickness, and length. The outer diameter of steel pipes can range from small sizes, such as ¼ inch (6.35 mm) or ⅛ inch (3.175 mm), to larger sizes like 48 inches (1219.2 mm) or even more for specialty applications. The wall thickness of steel pipes can also vary greatly, with options ranging from thin-walled pipes with a few millimeters of thickness to thick-walled pipes with several inches of thickness. In terms of length, steel pipes are typically produced in standard lengths of 20 feet (6.1 meters) or 40 feet (12.2 meters). However, custom lengths can also be manufactured based on specific project requirements. It is important to note that these dimensions are just general examples and may not cover all the possible variations in steel pipe sizes. Therefore, it is always recommended to consult relevant industry standards and specifications to determine the precise dimensions required for a particular application.

- Q: How are steel pipes used in the manufacturing of desalination plants?

- Steel pipes are used in the manufacturing of desalination plants to transport the seawater from the intake point to the treatment facilities. These pipes are durable, corrosion-resistant, and can withstand the high-pressure conditions required for the desalination process.

- Q: What are the different pipe fittings used with steel pipes?

- Some of the different pipe fittings used with steel pipes include elbows, tees, couplings, unions, reducers, flanges, and caps.

Send your message to us

ASTM A 106 Seamless Steel Pipe/Seamless Pipe/API Seamless Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords