GB ASTM A106/53 API 5LSeamless Steel Pipes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are company that have many years experience and professional manager team and engineer team and sales team, sure we will provide you high quality of pipe and professioanl service.

Seamless pipe possesses a hollow section and without seam around the strip steel. It is made with solid bar or steel ingot by perforating machine. As the facture process does not include any welding, seamless pipes are considered to be stronger and more durable. Generally speaking, seamless pipe has better pressure resistance and security than other classifications, and was usually more easily available than welded pipe.

2、Main Features of the Seamless Pipe:

• High working accuracy

• High strength

• Small inertia resistance

• Strong therming dissipine ability

• Good appearance

• Reasonble price

3、Seamless Pipe Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range: OD: 21.3-610mm, WT:6-70mm, length:6-12m or according to the requirement of clients.

3) Executive standards: GB, ASME API5L.ASTM A 106/A53,Despite of the above standards, we can also supply seamless steel pipe with standard of DIN, JIS, and so on, and also develop new products according to the requirements of our clients!

4) Surface: black lacquered, varnish coating or galvanized.

5) Ends: Beveled or square cut, plastic capped, painted.

6) Packing: bundles wrapped with strong steel strip, seaworthy packing.

4、Packaging & Delivery:

Packaging Details: | seaworthy package, bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe:

①How is the quality of your products?

We have many years business experience in this area, and we have professional engineer and manager team and sure we can provide you high quality production and professional service.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

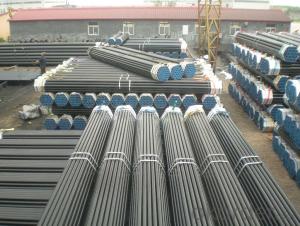

6、Seamless Pipe Images:

- Q: How are steel pipes used in the construction of desalination plants?

- Steel pipes are commonly used in the construction of desalination plants for various purposes. They are used to transport water from the intake point to the plant, as well as to distribute the treated water to the storage tanks or other destinations. Steel pipes are also employed in the plant's infrastructure, such as for the installation of pumps, valves, and other equipment. Additionally, steel pipes are utilized for the discharge of brine, which is the concentrated salt solution generated during the desalination process. Overall, steel pipes play a crucial role in ensuring the efficient and reliable operation of desalination plants.

- Q: What are the properties of steel that make it suitable for pipe manufacturing?

- Due to its unique properties, steel is highly favored as a material for manufacturing pipes. The exceptional strength and durability of steel allow it to withstand high pressure and extreme temperatures, ensuring the safe transportation of fluids and gases over long distances without the risk of leakage or breakage. Another significant advantage of steel is its resistance to corrosion. Unlike other materials that can degrade when exposed to corrosive substances such as water, chemicals, and gases, steel remains highly resistant to corrosion. This quality makes steel pipes long-lasting and reliable. Furthermore, steel is a versatile material that allows for the production of pipes in various sizes and shapes. This flexibility enables customization to meet specific project requirements, making steel pipes suitable for a wide range of applications, including water supply, oil and gas transmission, sewage systems, and structural support. Moreover, steel possesses excellent thermal conductivity, which is crucial for applications involving the transportation of hot or cold fluids. Steel pipes efficiently transfer heat, ensuring minimal energy loss during the process. Additionally, steel is an environmentally friendly option for pipe manufacturing due to its recyclability. Steel pipes can be recycled and reused, reducing the demand for new raw materials and minimizing waste generation. In conclusion, the properties of strength, durability, corrosion resistance, versatility, thermal conductivity, and recyclability make steel the ideal choice for pipe manufacturing. These properties guarantee the reliability, efficiency, and longevity of steel pipes in various industries and applications.

- Q: How are steel pipes classified according to their wall thickness?

- Steel pipes are classified according to their wall thickness into various categories such as standard, extra strong, and double extra strong.

- Q: How are steel pipes used in the construction of stormwater drainage systems?

- Steel pipes are commonly used in the construction of stormwater drainage systems due to their durability and strength. They serve as underground conduits to efficiently transport stormwater away from built-up areas, preventing flooding and water damage. Steel pipes offer high resistance to external pressure and are capable of withstanding heavy loads, making them suitable for underground installations. Additionally, their corrosion-resistant properties ensure long-term effectiveness and minimize maintenance requirements. Overall, steel pipes are essential components in stormwater drainage systems, providing reliable and efficient water management solutions.

- Q: What is the thermal conductivity of steel pipes?

- The thermal conductivity of steel pipes can vary depending on the specific type of steel and its composition, but generally, steel has a relatively high thermal conductivity compared to other materials. It is typically around 50-60 W/m·K.

- Q: 304 stainless steel tube with the diameter of 25*2-3 is what mean

- This is according to the "water drawing standards" (GBT50106-2001) in 2.4.2-2 seamless steel pipe, welded steel pipe (straight or spiral seam), brass, stainless steel pipe, pipe diameter should be D diameter * thickness representation (such as D108 * 4 and D159 * 4.5); and the provisions of the habit of acting D with seamless pipe diameter.

- Q: How are steel pipes used in the manufacturing of renewable energy systems?

- Steel pipes are extensively used in the manufacturing of renewable energy systems for various purposes. They are commonly used as structural components, providing strength and stability to wind turbines, solar panel supports, and hydroelectric power systems. Steel pipes are also utilized for transporting fluids such as water, steam, or gases in energy generation processes. Furthermore, they are essential in the construction of geothermal energy systems, where they are employed to create underground heat exchangers and piping networks. Overall, steel pipes play a crucial role in the efficient and reliable functioning of renewable energy systems.

- Q: Can steel pipes be used for transporting gases?

- Yes, steel pipes can be used for transporting gases. Steel pipes are known for their strength, durability, and resistance to corrosion, making them an ideal choice for transporting various gases over long distances. Additionally, steel pipes can handle high pressure and extreme temperatures, ensuring the safe and efficient transportation of gases.

- Q: What are the different types of joints used in steel pipes?

- There are several types of joints commonly used in steel pipes, including threaded joints, welded joints, flanged joints, and grooved joints.

- Q: What are the factors to consider when selecting steel pipes?

- When selecting steel pipes, some of the key factors to consider include the intended use or application, the required strength and durability, the size and dimensions of the pipes, the corrosion resistance properties, the cost and availability, and any specific industry or regulatory requirements.

Send your message to us

GB ASTM A106/53 API 5LSeamless Steel Pipes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords