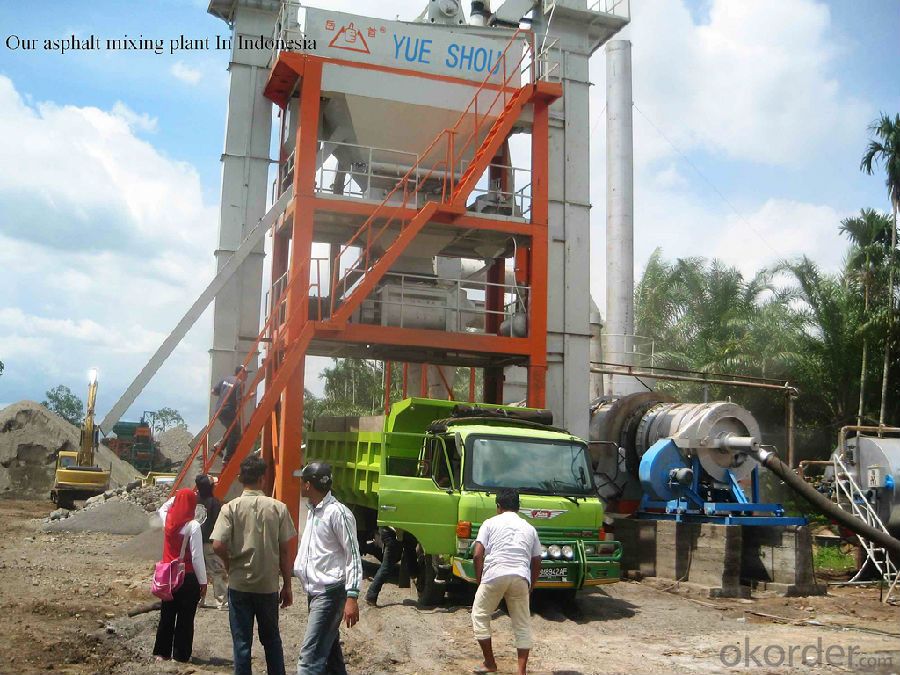

Asphalt Batching Plant with productivity of 64 t/h

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 1 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LB800 Asphalt Mixing Plant with capacity 64t/h

Item | Description | Qty. (set) |

01 | Cold Aggregate Batching Machine and Feeders Group of four components, unit capacity of the aggregate hopper is 5M³ (full hopper), total capacity is 20M³; Adopts imported variable-frequency governor Continuous dosing belt & and driving reduction motor group, group of 4 units; The electric vibrato: 2 units | 1 |

02 | Feeding belt conveyor | 1 |

03 | The Drying Drum Ø1450×6300 MM, rotating speed: 11.3 RPM; Cylinder on frame, Rotation drive through electric motor and reduction box, The heat-preservation is 50mm rack wool and stainless steel | 1 |

04 | EBICO Gas burners Fuel :Natural gas | 1 |

05 | Cyclone dust collector |

|

06 | Bag dust collector |

|

07 | The hot aggregate elevator: capacity 80 T/H | 1 |

08 | The filler bin: 0.6 M³, the capacity of the filler elevator: 25T/H | 1 |

08 | The vibrating screen unit 4 grades, capacity 80T/H | 1 |

09 | The hot aggregate storage bin 4 numbers, the total volume is 10 M³, 4 units level indicator, temperature detector | 1 |

10 | The weighing devices The weighing unit for powder, aggregate and bitumen (each has one unit) | 1 |

11 | The mixing tower The main tower with supporting legs, repairing platform and guardrail | 1 |

12 | The mixer Capacity: 800 KG/batch, the motor power: 30KW | 1 |

13 | Vibration screen |

|

14 | Asphalt supply system and heating system 2 units 25 tons bitumen tank with hot oil heating system |

|

15 | Pneumatic control system | 1 |

16 | Electric control system |

|

17 | Control room |

|

18 | With 30ton bottom-set finished mixture storage tank | 1 |

- Q: What raw materials and equipment do you need for your own admixture?

- Admixtures seem simple, but they are actually a practical science. You want to get the ideal admixtures from the books or the web, "that's quite", and you're in the concrete mixing station. The concrete cost control of the mixing station is relatively strict, and the performance of the admixture is different

- Q: The main components of a mixing station

- Feeding system: aggregate bucket, aggregate weighing hopper, flat belt machine, inclined belt conveyor. Mixing system: the main machine is a double-deckshaft mixer, reducer, cement weighing hopper, water and additive weighing hopper. Cement supply system: cement warehouse, screw conveyor, air compressor, screw electronic. Automatic water supply system: water tank, pump, pipe. Electrical operating system: computer console, electric control cabinet, operation room. Operation control system: microcomputer control or manual control.

- Q: What type of concrete mixer is needed for each hour of concrete 90 cubic meters?

- Many manufacturers will say that the HZS90 station is the one that makes 90 square concrete. In fact, the HZS90 station is supposed to produce 90 square concrete when it is in theory, and it is actually not up to 75 square

- Q: Cement warehouse introduction, storage reserves?

- There's nothing to come, but warm and young About 200 tons

- Q: What are the supporting facilities for the concrete mixing stations?

- Mixing station can be divided into single and double machine stand, as the name implies, stand-alone station each station has a mixing console, the double machine station has two mixing console, each mixing console has a discharging mouth, so double machine mixing plant is a stand-alone station 2 times of production capacity.

- Q: What are the ingredients for the concrete mixing stations?

- The main ingredients of admixtures are: the mother fluid, the composition of the air and the composition of the mixture, and the water. The concrete formulations are determined according to the different materials of concrete, which is usually the mother solution and the adjustment time. The parent fluid is itself well adapted and does not require a lot of material.

- Q: What is the special work of the concrete mixing station

- One of the features of the high-performance concrete mixer line is the low water ratio. In order to ensure its liquidity, it must be mixed with an efficient water reducer. Therefore, it is necessary to select cement that is suitable for low water cement ratio. One is the composition of fineness and particles, and the other is the early hydrogenation after the addition of water.

- Q: What is the difference between a concrete mixer and a concrete mixer

- Since a lot of people think commodity concrete, concrete stand and commodity concrete mixing floor are production of commodity concrete equipment, then there is no too big difference, most is just a big a small, one high a dwarf. But what's the difference between these two devices? So let's just do a little bit of an introduction. First commercial concrete, concrete stand and mixing building systems: the difference between a bituminous concrete stand composed of five systems, such as material supply system, measuring system, mixing system, electric control system, etc. The stirring building is relatively simple.

- Q: Concrete mixstations belong to no special equipment

- The boiler is a special equipment in the stirring station.

- Q: Does the concrete mixing station name have the name of the businessman concrete

- Original concrete is the construction unit oneself mix, the existing specialized manufacturer presses the need to produce concrete, the product that produces is concrete.

Send your message to us

Asphalt Batching Plant with productivity of 64 t/h

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 1 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches