API 5CT L80 Casing And Tubing Pipe in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Tubing:60.3mm-114.3mm

2,Casing:114.3mm-508mm,

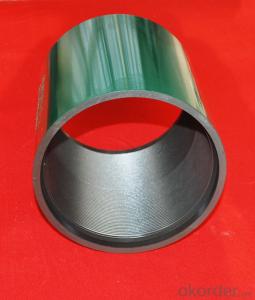

3,Coupling:60.3mm-508mm

4,pup joints:60.3mm-114.3mm

5,seamless steel pipe:89mm-273mm

API 5CT L80 Casing And Tubing Pipe

Product | Oil Casing Pipe | ||

O.D | 139~273mm | W.T | 3.68~16.13mm |

Length | 1-12M , according to customers' requirements | ||

Standard | ASTM A106,ASTM A53,API 5L,API 5CT | ||

Material | H40,J55,K55,N80,L80,P110,Q235B,Q345B GRB/X42/X46/X52/X56/X60/X65/X70/X100 | ||

Inspection | X-ray inspection,manual ultrasonic inspection,surface inspection, hydraulic testing,ultrasonic detection | ||

Technique | Cold drawn,Hot rolled,heat extrusion | ||

Certifications | 1.API Spec 5L & API Spec 5CT certificates; 2.ISO9001:2000 International Quality System certificate; 3.ISO14001:2004 Environmental Management System certificate | ||

Usage | 1.water,petroleum,natural gas transportation 2. Aerospace,shipbuilding, automobile manufacturing 3.boiler,coal,chemicals | ||

Main market | USA,Middle east,South America,Europe,Southeast Asia,Australia,Africa | ||

Productivity | 5000Tons/Month | ||

Packing | Plastic caps, bundle, black painting,3PE or negotiation | ||

Remarks | 1)Payment terms : T/T,L/C 2)Trade Terms : FOB / CFR /CIF 3)Minimum quantity of order:10 MT 4)Delivery period :15-20 days after receiving deposit | ||

- Q: How are steel pipes used in the manufacturing of pressure vessels?

- Steel pipes are commonly used in the manufacturing of pressure vessels due to their high strength and ability to withstand high pressure. These pipes are utilized as the primary material for constructing the shell of the pressure vessel, providing a robust and reliable structure. Additionally, steel pipes offer excellent resistance to corrosion, making them suitable for various industries and applications where pressure vessels are required, such as oil and gas, chemical processing, and power generation.

- Q: How do you calculate the flow rate through a steel pipe?

- Several factors need to be considered in order to calculate the flow rate through a steel pipe. The crucial factors include the pipe's diameter, the pressure difference across the pipe, and the properties of the fluid flowing through it. Accurate measurement of the inside diameter of the steel pipe is the first step. This measurement is vital as it determines the cross-sectional area through which the fluid flows. Ensure that the units used for the diameter measurement are consistent with the units used for other measurements. Next, determine the pressure difference across the pipe. This can be accomplished by measuring the pressure at two points along the pipe, typically at the inlet and outlet. It is important to take the pressure measurements at the same height in order to avoid any discrepancies. The pressure difference is usually given in units of pressure, such as psi, kPa, or bar. Once you have the diameter and pressure difference, you can utilize either the Bernoulli equation or the Darcy-Weisbach equation to calculate the flow rate. The Bernoulli equation establishes a relationship between the pressure difference and the fluid's velocity. However, this equation assumes ideal conditions and overlooks factors like friction losses, viscosity, and turbulence. On the other hand, the Darcy-Weisbach equation is more accurate as it considers these factors. To employ the Darcy-Weisbach equation, you must be aware of the fluid's properties that flow through the pipe, such as density and viscosity. These properties can be determined either through experimentation or by referring to literature values. After gathering all the necessary information, you can use the Darcy-Weisbach equation: Q = (π/4) * D^2 * √[(2 * ΔP) / (ρ * f * L)] Where: Q represents the flow rate, measured in cubic meters per second or any other consistent units. D is the diameter of the pipe, measured in meters or any other consistent units. ΔP is the pressure difference across the pipe, measured in Pascals or any other consistent units. ρ is the density of the fluid flowing through the pipe, measured in kilograms per cubic meter or any other consistent units. f signifies the friction factor, which relies on the Reynolds number and the roughness of the pipe. L represents the length of the pipe, measured in meters or any other consistent units. By substituting the appropriate values for all the variables, you can accurately calculate the flow rate through the steel pipe.

- Q: What is the role of steel pipes in sewage systems?

- Steel pipes play a crucial role in sewage systems as they are used to transport wastewater and sewage from various sources to treatment plants or disposal areas. Their strength, durability, and resistance to corrosion make them ideal for handling the often harsh and corrosive nature of sewage. Additionally, steel pipes can withstand high pressures and provide a reliable and long-lasting solution for sewage transportation, ensuring the efficient and safe functioning of sewage systems.

- Q: What's the gate number of the precision steel pipe?

- This kind of steel tube and ordinary hot-rolled seamless steel pipe and cold drawn seamless steel tube in the outer surface is different from the outer surface, and the diameter of the smooth finish of precision steel tube, stainless steel color and the same, inside and outside surface due to manufacturing reasons with a layer of oil.

- Q: How are steel tubes represented?

- If you speak of steel pipe, if it is water. Gas transmission pipe, then it is said: nominal diameter refers to the inner diameter. The units are millimeters or inches. [for example, water pipes with phi 25. It means that the nominal diameter (diameter) is 25mm (or an inch) steel pipe.

- Q: Can steel pipes be used for conveying slurry?

- Yes, steel pipes can be used for conveying slurry. Steel pipes are widely used in various industries for transporting different types of fluids, including slurry. Slurry is a mixture of solid particles suspended in a liquid, and steel pipes are well-suited for handling such mixtures due to their strength, durability, and resistance to corrosion. Steel pipes are also known for their high-pressure and high-temperature capabilities, making them suitable for conveying slurry in demanding applications such as mining, dredging, and wastewater treatment. Additionally, steel pipes can be easily welded, allowing for the construction of long pipelines that can efficiently transport slurry over long distances. However, it is important to consider the specific characteristics of the slurry being conveyed, such as particle size, density, and abrasiveness, to ensure proper pipe selection and design for optimal performance and longevity.

- Q: Can seamless steel pipe and ordinary steel pipe be welded?

- Steel pipe and seamless linking points, you said should refers to ordinary steel pipe joints, if only consider the butt welding problem, two kinds of steel can be welded. But the mechanical properties of the seamless steel pipe and tube with different, generally the main difference is the two kinds of steel can withstand the pressure of the former than the latter to be good.So if your project is seamed steel pipe can be, then the two pipe welding, welding and butt welding interface is completely no problem.

- Q: How do you transport and store steel pipes?

- Transporting and storing steel pipes requires careful planning and adherence to safety guidelines. Here are the steps involved in transporting and storing steel pipes: 1. Determine the appropriate mode of transportation: Depending on the quantity and weight of the steel pipes, you can choose between transportation by truck, train, or ship. Evaluate the distance, logistics, and cost-effectiveness of each option before making a decision. 2. Package and secure the steel pipes: Proper packaging is crucial to prevent damage during transit. Bundle the pipes together using steel strapping or banding. Ensure that the bundles are secured tightly to prevent any shifting or movement during transportation. 3. Use appropriate lifting equipment: When loading and unloading the pipes, use suitable lifting equipment such as cranes, forklifts, or hoists. Ensure that the equipment is capable of handling the weight and length of the pipes safely. 4. Protect against moisture and corrosion: Steel pipes are susceptible to moisture and corrosion, which can weaken their structural integrity. Before transportation, apply a protective coating or wrap the pipes with waterproof materials. Additionally, consider using moisture-absorbing desiccants or placing the pipes on pallets to elevate them off the ground. 5. Plan for safe storage: If storing the steel pipes for an extended period, choose a dry and secure location. Ensure that the storage area is well-ventilated and free from direct exposure to sunlight, rain, or extreme temperatures. Use racks or pallets to keep the pipes off the ground and prevent contact with moisture. 6. Inspect for damage: Before transportation and after storage, conduct thorough inspections to identify any damage or signs of corrosion. This will help you address any issues promptly and ensure the integrity of the steel pipes. Remember to comply with local regulations and safety guidelines specific to your region when transporting and storing steel pipes. By following these steps, you can ensure the safe and efficient transportation and storage of steel pipes, minimizing the risk of damage and maintaining their quality.

- Q: How are steel pipes used in the construction industry?

- Steel pipes are widely used in the construction industry for various purposes such as structural support, conveying fluids and gases, and underground utility systems. They are commonly used in building frameworks, bridges, and high-rise structures due to their strength, durability, and resistance to extreme weather conditions. Additionally, steel pipes are utilized for plumbing and drainage systems, providing a safe and efficient way to transport water, sewage, and other fluids.

- Q: How are steel pipes used in the mining industry?

- Steel pipes are commonly used in the mining industry for various purposes such as transporting water, slurry, and other materials, as well as for ventilation and support systems in underground mines.

Send your message to us

API 5CT L80 Casing And Tubing Pipe in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords