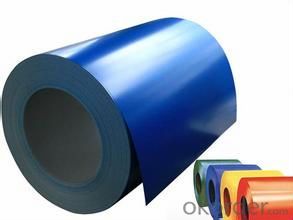

anto acid and alkali prepainted steel coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Dimensions: | Thick:0.16mm-1.0mm | Grade: | Thin steel SGCC DX51D Carbon steel |

| Application: | construction, container building | Shape: | Rolls | Alloy Or Not: | Non-alloy |

| Width: | 1000mm | Weigth/roll: | 4.5tons | Zinc coating: | 40g/sqm |

| Thickness: | 0.4mm |

Packaging & Delivery

| Packaging Detail: | Waterproofing PE film Iron strip |

| Delivery Detail: | 20 days |

Specifications

Anti corrossion prepainted steel coil

ASTM, GB, CE, GOST certified

SPCC DX51D steel base

Ship to Russia, Malaysia, Brazil

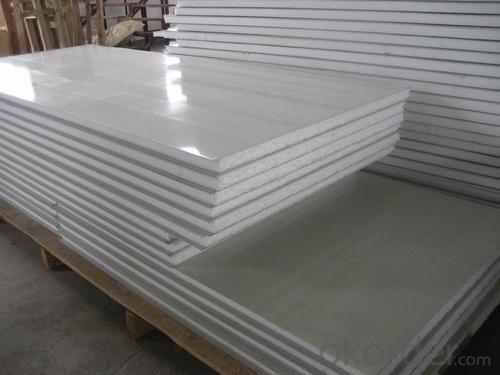

Prepainted Steel Sheet

Product Introduction:

Color coated steel sheet is a novel precoated band steel product which rapidly develops internationally in the recent thirty years. It is made by performing processes such as chemical pretreatment, primary coating and fine coating on a high-speed continuous operating unit. The color coated steel sheet has the advantages of excellent decorativeness, formability, corrosion resistance and environment friendliness, strong adhesive force of the coating, and long-time color freshness. Achieving good economic benefits such as substituting steel for wood, efficient construction, energy saving, pollution prevention, etc., it has become an ideal material for manufacturing building sheets, external decorative materials, home appliances and electric appliances at present.

Under the philosophy of “Vigoriously Developing Enterprise by Technology”, the company adopts American direct-fired heating technology, greatly reducing energy consumption and reducing cost; the roller coater adopts the most advanced French technology on the world, and the plant construction adopts high-cleanliness sealing method, meeting the requirements of dust-free production and ensuring product quality; to meet the demand of the market on high-end color-coated sheets, the company has increased three-color printing process, which meets the demand of high-end users. At present, most domestic sheets are ordinary color-coated sheets, so that high-grade color-coated sheets with high technical content have wide market prospect in China.

Product Specification:

Item | Norminal Size/mm | |

Norminal Thick | 0.15-1.2 | |

Norminal Width | Steel Sheet and Strip | 1000-1250 |

Slit Wide Strip | <600 | |

Norminal Length | Steel Sheet | 1000-8000 |

Steel Strip and Silt wide strip | 610/508 | |

- Q: What are the different methods of tension leveling for steel coils?

- There are several methods of tension leveling for steel coils, including roller leveling, stretcher leveling, and temper leveling. In roller leveling, the coil passes through a series of rollers that apply pressure to remove the internal stresses and flatten the material. Stretcher leveling involves stretching the coil beyond its yield point to remove the unevenness and then allowing it to spring back to a flat state. Temper leveling uses heat treatment to relieve the internal stresses and bring the coil to a flat condition. These methods provide different ways to achieve a level and flat surface for steel coils.

- Q: What are the different types of edge conditions in steel coils?

- There are several types of edge conditions in steel coils, including mill edge, slit edge, rounded edge, deburred edge, and trimmed edge.

- Q: I don't know why but I'm having a VERY difficult time finding the melting point of 1008 steel.

- It is still the same for 1008 steel. Go to the bottom and see the listing of the grades it covers. Since the only difference between the 1006 and 1008 steel is a few micro amounts of alloys and by far the greatest majority or main component is iron (99%), as a general melt temperature , 2750 F is the melt temperature at which the other alloys are added to the charge to fine tune the mix. Just like adding salt to distilled water actually lowers the boiling point of water, adding alloys to iron decreases the melting point of iron. The iron melts at 2800F, but once alloys to make the 1008 grade are added, it decreases melt temp to 2750F. Since the melting point of pure iron is 2800F, the temperature is actually decreased by adding these impurities of alloys. These alloys are tested while the mix is starting to come down from a pure melt, steel is sampled. and then alloys below are checked and added to make the 1008 steel. The steel is maintained at 2750 F so that the less volatile alloys don't boil off before combining with steel. Minimum Properties Ultimate Tensile Strength, psi 43,900 - 51,900 Yield Strength, psi 26,100 - 34,800 Elongation 42 - 48% Chemistry Iron (Fe) 99% Carbon (C) 0.08% Manganese (Mn) 0.6% max Phosphorus (P) 0.035% max Copper (Cu) 0.2% min Sulfur (S) 0.04%

- Q: What are the different coil leveling line configurations used for steel coils?

- The steel industry utilizes various coil leveling line configurations to meet specific requirements and preferences. Some commonly employed configurations include: 1. Straightener: Employed to rectify coil shape defects or distortion. It consists of rollers that gradually straighten the coil. 2. Leveler: Ensures consistent thickness throughout the coil. Utilizes rollers to flatten the coil to the desired thickness. 3. Combination Straightener/Leveler: Integrates both straightening and leveling functions into a single machine. Combines rollers and straightening elements for shape correction and thickness leveling in one pass. 4. Looping Pit: Allows continuous processing of accumulated coils. Serves as a buffer between the entry and exit sections of the leveling line, accommodating variations in coil supply and demand. 5. Tension Leveler: Applies tension during leveling to remove shape defects and achieve a flat, uniform surface. 6. Rotary Shear: Incorporates a synchronized rotary shear to cut the leveled coil accurately and precisely. These examples showcase the diverse coil leveling line configurations used in the steel industry. The choice of configuration depends on factors such as desired product specifications, coil dimensions, processing speed requirements, and budget considerations.

- Q: How are steel coils shipped internationally?

- To ensure the safe and efficient transportation of steel coils internationally, various methods are utilized. The most commonly employed technique involves container shipping, where steel coils are placed in standard shipping containers. These containers are specifically designed to handle heavy and bulky cargo like steel coils. To load the steel coils into the containers, they are typically stacked horizontally and secured with steel strapping or metal bands to prevent any movement during transit. This ensures stability and minimizes the risk of damage. Additionally, wooden or metal dunnage may be used to separate and secure the coils, further preventing any shifting. Once loaded, the containers are sealed and transported to the port using trucks or trains. At the port, the containers are loaded onto cargo ships utilizing crane or specialized equipment, such as roll-on/roll-off (RO-RO) vessels or semi-submersible ships. These ships provide a protected environment for the steel coils during the journey, shielding them from adverse weather conditions and potential damage. Throughout the voyage, the steel coils are subjected to various safety measures to prevent corrosion and maintain their integrity. These measures include the application of protective coatings, such as oil or special paints, as well as the use of desiccants or humidity control systems inside the containers to regulate moisture levels and minimize the risk of rusting. Upon arrival at the destination port, the containers are unloaded from the ship and transferred to trucks or trains for further transportation to their final destination. At this stage, the steel coils may undergo customs clearance and inspection procedures before being delivered to the intended recipients. In conclusion, the international shipping of steel coils requires careful planning, secure packaging, and the utilization of specialized containers and equipment to ensure their safe and successful transport.

- Q: How do steel coils contribute to durability and longevity in products?

- The durability and longevity of products are greatly enhanced by steel coils, mainly because of their strength, stability, and resistance to corrosion. Firstly, steel is widely known for its exceptional strength, making it the perfect material for applications where durability is crucial. Steel coils, which are essentially tightly rolled steel, add strength and structural integrity to products. The stability offered by steel coils is another important factor in improving product durability. The tightly rolled structure of the coils ensures that they maintain their shape and resist deformation even under heavy loads or extreme conditions. This stability is particularly significant in industries like construction and automotive, where products need to withstand rigorous usage for long periods of time. Furthermore, steel coils have excellent resistance to corrosion, primarily due to the presence of protective coatings. These coatings, such as zinc or other metallic alloys, act as a barrier against moisture and environmental elements that cause rust and degradation. By preventing corrosion, steel coils help extend the lifespan of products, making them more durable and reliable. Moreover, steel coils can be customized to meet specific requirements, such as different thicknesses, widths, or surface finishes. This versatility allows manufacturers to tailor the steel coils to their desired application, ensuring optimal performance and longevity in their products. To sum up, steel coils contribute to the durability and longevity of products through their strength, stability, corrosion resistance, and customization capabilities. By incorporating steel coils into various industries and applications, manufacturers can ensure that their products last longer and provide greater reliability to consumers.

- Q: How are steel coils used in the production of transportation equipment?

- Steel coils are used in the production of transportation equipment, such as automobiles, ships, and trains, to create various structural components. These coils are typically shaped and formed into parts like chassis, frames, bodies, and panels, providing strength, durability, and stability to the vehicles. Additionally, steel coils can be used in the manufacturing of wheels, axles, and suspension systems, ensuring reliable performance and safety in transportation equipment.

- Q: Can steel coils be coated with thermally conductive materials?

- Yes, steel coils can be coated with thermally conductive materials. These materials are often applied as a thin layer or coating onto the surface of the steel coils to enhance their thermal conductivity. This coating helps in the efficient transfer of heat through the coils, making them suitable for various applications that require effective heat dissipation or thermal management.

- Q: Im looking to learn guitar and i was wondering if steel strings are too hard to use as a beginner. I am also self teaching so any good lesson books/starting guitar recommendations are welcome !! thanks.

- Steel strings are fine for a beginner. I learned to play on Steel strings and I have always preferred them to nylon strings.

- Q: My teacher says if they were that they would still be standing today. I'm not sure if he means the reinforced steel in the concrete beams, columns etc or if the whole beams and columns floor etc were were made of reinforced steel.

- Reinforced Steel is found in concrete, and if the towers were built with reinforced concrete (concrete beams with rebar) then they would likely still be standing. The twin towers were made of steel. When steel is heated up, it deforms and collapses, which is why it didnt stand up. One of the top 2 things against steel is that it is not fire resistant.

Send your message to us

anto acid and alkali prepainted steel coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords