Best Packaging Tape for Shipping - Anti-Slip Tape with Different Colors and Designes Logo Printing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

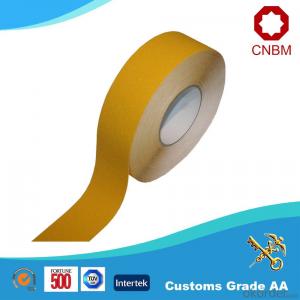

Introduction of Anti-slip Tape

1. Structure: Surface: choice anti-slip sand, rubber anti-slip fiber, sand-free special anti-slip material; Middle Layer: PET, PP, PVC and aluminum, etc. Base glue: ready-to-use waterproof strong viscose. Base paper: white/leather silicone paper.

2. Appearance of Colors: Black, gray, red, orange, blue, between yellow and black, red and white, transparent, white, reflective, night light-emitting, etc. printing a variety of beautiful picture and patterns according with customer requirements.

3. Types: 1) super anti-slip 2) cozy anti-slip 3) general anti-slip 4) easy-to-clean

Application of Anti-slip Tape

1) Equipment: skateboard, scooter, running machine, exercise machine, machine tool, footplate of printing machine, passages on buses or stairways.

2) Locations: Kindergarten, school, swimming pool, nursing home, bus station, subway station, train station, pier, hotel, club house, kitchen, washing room, playground, health and recreation facilities, entrance of elevator, pedestrian slope, shopping mall, working area and deck, etc.

3) Also applicable to tourist car, ship, tow truck, truck, aircraft, hanging ladder, large- or small-sized power equipment.

Advantage of Anti-slip Tape

1.Anti-slip tape, superb tack and adhesion to surface, Strong grip that is ensured because of an excellent adhesive backing.

2. Peak performance even under extreme conditions of pressure and temperature, which can stick to all types of surfaces.

3. Consistent quality

4. on time delivery

5. Effective and timely communication

6. Competitive price

Packing of Anti-slip Tape

individually wrapped, shrink, carton.

6rolls/shrink, about 36~100rolls/carton(according to different specifications)

carton size : any carton size as your request

Pictures of Anti-slip Tape

Specification of Anti-slip Tape

| Material | PVC, PP, PE |

| Adhesive Side | Single Sided. |

| Adhesive | Acrylic, Water based acrylic adhesive. |

| Acrylic | Water based acrylic adhesive. |

| Color | Transparent clear/yellowish /tan brown/blue/red/ green |

| Normal thickness | 45mic, 46mic, 48mic,50mic, 52mic, 55mic, 60mic, 65mic, 70mic etc |

| Color | black, white, clear, blue, and print as customer’s requirment. |

| Mesh | 40# 60# 80# 100# 150# |

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

5.What are the international commodity codes for these products?

HS Code: 48231900.

6.Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

- Q: Is packaging tape resistant to tearing or ripping?

- Yes, packaging tape is typically resistant to tearing or ripping. It is designed to provide a strong and secure seal on packages, ensuring that they remain intact during transit or handling. Packaging tape is made from durable materials such as polypropylene or reinforced paper, which offer high tensile strength and tear resistance. Additionally, many packaging tapes have adhesive properties that further enhance their resistance to tearing or ripping. However, it is important to note that the strength and tear resistance of packaging tape may vary depending on the specific brand or type of tape used.

- Q: Can packaging tape be used for sealing packages with high-value contents?

- Indeed, packaging tape proves useful in sealing packages that contain valuable items. Designed with the specific purpose of ensuring the secure closure of packages, it offers protection against tampering, moisture, and transit-related harm. Possessing strength and durability, packaging tape usually boasts a resilient adhesive backing that guarantees a lasting seal. By employing packaging tape correctly, one can effectively safeguard packages that hold valuable contents, thereby guaranteeing their safe arrival. However, it is crucial to bear in mind supplementary security precautions, such as utilizing tamper-evident tape or incorporating additional layers of protection, depending on the worth and fragility of the items contained within.

- Q: Can packaging tape be used for sealing automotive parts or equipment?

- Sealing automotive parts or equipment with packaging tape is generally not recommended. Packaging tape is designed for securely sealing lightweight materials like cardboard boxes, but it may lack the durability and adhesive strength necessary for automotive use. Automotive parts and equipment experience various conditions like heat, vibrations, and exposure to chemicals, which can degrade or weaken packaging tape over time. Furthermore, specialized sealing methods like gaskets, seals, or automotive-grade adhesives are typically required for proper functionality and long-lasting performance. Therefore, it is generally advisable to use sealing methods and materials specifically designed for automotive applications to ensure desired performance and reliability.

- Q: What is packaging tape?

- Packaging tape is a type of adhesive tape that is specifically designed for sealing and securing packages and boxes. It is commonly used in various industries, shipping companies, warehouses, and households to ensure that packages are properly sealed and protected during transportation or storage. This type of tape is typically made from durable materials such as polypropylene or polyester, which makes it resistant to tearing and provides strong adhesion. Packaging tape is available in different widths and thicknesses to accommodate various package sizes and weights. It is often transparent or brown in color, but can also come in different colors or patterns for aesthetic purposes or to differentiate between different types of packages. Overall, packaging tape is an essential tool in ensuring the safety and security of packages during transit or storage.

- Q: Can packaging tape be used for sealing packages with breakable items like ceramics?

- Yes, packaging tape can be used for sealing packages with breakable items like ceramics. However, it is important to ensure that the tape is applied properly to provide adequate support and protection for the fragile items. In addition to using packaging tape, it is recommended to use additional protective materials such as bubble wrap or foam padding to cushion the ceramics and minimize the risk of damage during transit.

- Q: Does packaging tape come in different adhesion levels for various surfaces?

- Yes, packaging tape does come in different adhesion levels for various surfaces. There are packaging tapes available with different adhesive strengths to adhere to different surfaces such as cardboard, plastic, or metal. This allows for better packaging and ensures that the tape securely sticks to the desired surface.

- Q: Is packaging tape safe for use on photos or artwork?

- Yes, packaging tape is safe for use on photos or artwork as long as it is acid-free and archival quality tape. This type of tape will not harm or damage the photos or artwork over time.

- Q: Can packaging tape be used for sealing foam?

- Yes, packaging tape can be used for sealing foam. It provides a secure and reliable way to hold foam pieces together or close gaps in foam packaging. However, it's important to note that there are specific types of tape designed for foam sealing, such as foam tape or adhesive-backed foam strips, which may offer better results and durability.

- Q: Can packaging tape be used for securing pallet loads?

- Yes, packaging tape can be used for securing pallet loads. Packaging tape is commonly used to secure boxes and packages, but it can also be used to reinforce and secure pallet loads. It helps to hold the items on the pallet together, preventing them from shifting or falling off during transportation or storage. However, it's important to note that the effectiveness of packaging tape for securing pallet loads may depend on the weight and stability of the items being transported. In some cases, additional strapping or banding may be needed for extra security.

- Q: Can packaging tape be used for sealing packages with perishable items?

- No, packaging tape is not suitable for sealing packages with perishable items as it does not provide the necessary insulation or protection needed to maintain the freshness and quality of such items. It is recommended to use specialized packaging materials such as insulated boxes or coolers along with appropriate sealing methods for perishable items.

Send your message to us

Best Packaging Tape for Shipping - Anti-Slip Tape with Different Colors and Designes Logo Printing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords